- Kaydeli

- Torre de resfriamento de contrafluxo

Torre de resfriamento de contrafluxo

Catalog:Water Cooling Tower

Simply input your water flow rate (m³/h) and temperature difference (°C) to determine the ideal Flow around the Water Cooling Tower model. Our system will recommend the perfect match, ensuring optimal cooling efficiency and energy savings for your setup. 💧🌡️✅

💧 Capacidade de resfriamento: kW

🏷️ Recommended Tower Model: T

Working Principle of Counterflow Cooling Tower

Counterflow Cooling Towers are highly efficient systems designed for industrial cooling, HVAC applicationse large-scale commercial facilities. They utilize a counterflow air-water interaction principle, where water flows downward while air flows upward, maximizing heat exchange efficiency and minimizing water and energy usage.

Hot Water Entry 💦

Water Distribution System 🌧️

Air Circulation 🌬️

Heat Exchange 🔄

Drift Elimination 🚫💧

Cooled Water Collection 📥🔁

What is a Counterflow Cooling Towers?

Counterflow Cooling Towers are engineered for optimal cooling efficiency, low operational costse long-lasting reliability. Below are the key features that make them an ideal choice for industrial, commerciale HVAC cooling applications.

| Recurso | Descrição | Key Benefit |

|---|---|---|

| 🌬️ Counterflow Design | Opposing air-water flow pattern | Maximizes heat transfer |

| 🏢 Compact Structure | Vertical, space-efficient design | Ideal for tight spaces |

| 💦 Water Distribution | High-pressure nozzles | Uniform water coverage |

| ⚡ Energy Efficiency | Variable Speed Drives (VSD) | Reduced energy costs |

| 🔇 Noise Reduction | Low-noise axial fans | Quiet operation |

| 🚫 Drift Eliminators | Prevent water droplet escape | Minimized water loss |

| 🛡️ Durability | Weatherproof, corrosion-resistant | Long-lasting operation |

| 🧼 Easy Maintenance | Accessible modular design | Reduced downtime |

| 🌍 Sustainability Focus | Water and energy conservation | Eco-friendly operation |

| Recurso | Descrição | Key Benefit |

|---|---|---|

| Superior Heat Transfer | Counterflow design maximizes air-water interaction, ensuring higher thermal efficiency. | Optimal cooling performance with lower energy costs. |

| Eficiência energética | Variable Speed Drives (VSD) adjust fan speeds based on cooling demand, saving energy. | Up to 30% energy savings during operation. |

| Compact Design | Vertical structure requires minimal horizontal space, suitable for tight installations. | Maximizes space utilization. |

| Advanced Water Management | Smart drift eliminators minimize water loss and ensure even water distribution. | Improved water conservation and operational sustainability. |

| Noise Control | Low-noise axial fans and optional noise barriers reduce operational sound levels. | Suitable for noise-sensitive environments. |

| Durability | Corrosion-resistant materials and weatherproof design ensure long-lasting performance. | Reduced maintenance and replacement costs. |

| Easy Maintenance | Modular design allows quick access for cleaning, inspections, and repairs. | Minimizes downtime and operational disruptions. |

| Environmental Focus | Energy-efficient operation and low water waste meet environmental standards. | Aligns with sustainability goals. |

Advantages Over Other Cooling Towers

When selecting a cooling tower, understanding how Counterflow Cooling Towers compare to other common designs, such as Crossflow Towers, Round Cooling Towerse Closed-Circuit Cooling Towers, is essential. Below, we provide a clear comparison to highlight the unique advantages of Counterflow Cooling Towers.

| Recurso | Counterflow 🆚 | Crossflow 🔀 | Round 🌐 | Closed-Circuit 🔄 |

|---|---|---|---|---|

| Thermal Efficiency | High | Moderado | Low | High |

| Requisitos de espaço | Low | High | Low | Moderado |

| Water Distribution | Uniform | Variable | Uneven | Limited |

| Eficiência energética | High | Moderado | Low | Moderado |

| Noise Levels | Low | Moderado | High | Moderado |

| Manutenção | Easy | Moderado | Frequent | Specialized |

Recursos

Requisitos de resfriamento

Necessidades de capacidade de resfriamento

Understanding the cooling requirements for a Torre de resfriamento de contrafluxo is essential to ensure eficiência ideal, energy savingse consistent performance across various industrial and commercial applications. Below are the key parameters to consider when determining the right cooling capacity.

| Parameter | Descrição | Importance |

|---|---|---|

| 💦 Water Flow Rate (m³/h) | Measure the volume of water requiring cooling per hour, typically in cubic meters per hour (m³/h). | Ensures sufficient water volume for effective cooling. |

| 🌡️ Temperature Difference (ΔT) | Calculate the difference between the inlet hot water and the outlet cooled water temperature. | Directly impacts cooling capacity requirements. |

| ⚡ Cooling Capacity (kW) | Estimate the total heat load using the formula: Q = V × ΔT × 4.186. | Ensures the cooling tower meets system demand. |

| Fatores ambientais | Consider ambient temperature, humidity levels, and altitude for accurate sizing. | Adjusts cooling efficiency based on external conditions. |

| 🔄 Load Fluctuations | Account for peak and partial load conditions to ensure consistent performance. | Ensures flexibility during varying cooling demands. |

| 📊 Example Calculation | For 100 m³/h flow and 10°C ΔT: Q = 100 × 10 × 4.186 = 4,186 kW. | Provides a practical reference for capacity estimation. |

Application Scenarios for Flow Round Water Cooling Tower

Counterflow Cooling Towers are a widely used cooling solution known for their compact design, high efficiencye easy maintenance. These towers are ideal for processos industriais, HVAC systemse large-scale commercial applications where consistent cooling performance and space optimization are crucial.

HVAC Systems in Commercial Buildings

-Purpose: Maintain comfortable indoor temperatures by efficiently managing cooling loads.

-Applications: Office buildings, shopping malls, hotels, and hospitals.

-Advantage: Uniform air distribution ensures stable cooling across large spaces.

Industrial Manufacturing Facilities

-Purpose: Remove excess heat generated during manufacturing processes.

-Applications: Plastic molding, metalworking, chemical production.

-Advantage: High cooling efficiency supports continuous industrial operations without overheating.

Power Generation Plants

-Purpose: Cool steam condensers and auxiliary equipment to maintain system efficiency.

-Applications: Thermal power plants, nuclear power facilities.

-Advantage: Handles high heat loads with consistent cooling performance.

Processamento de alimentos e bebidas

-Purpose: Maintain precise cooling temperatures during production and storage.

-Applications: Dairy processing, beverage manufacturing, refrigeration systems.

-Advantage: Ensures product quality and safety through stable cooling.

Temperature Requirements for Square Cooling Towers

Understanding the temperature requirements of a Counterflow Cooling Towers is crucial to ensure optimal performance, eficiência energéticae consistent cooling output. Below are the key temperature parameters to consider when selecting and operating your cooling tower.

| Parameter | Optimal Range | Why It’s Important |

|---|---|---|

| 🌡️ Inlet Temperature | 30°C–50°C | Ensures effective cooling process |

| ❄️ Outlet Temperature | 25°C–35°C | Supports downstream system efficiency |

| 🔄 Temperature ΔT | 5°C–15°C | Indicates heat exchange efficiency |

| 💧 Wet Bulb Temp | Varies by region | Sets the theoretical cooling limit |

| ☀️ Seasonal Adjustments | Summer & Winter tuning | Maintains consistent performance |

| Fatores ambientais | Air Temp & Humidity | Directly impacts cooling efficiency |

Instalação e manutenção

Proper installation e regular maintenance are critical for ensuring Counterflow Cooling Towers’ optimal performance, energy efficiency, and long service life. Below are key considerations and best practices for both stages.

Diretrizes de instalação

📍 Preparação do local

You can choose a well-ventilated area with minimal obstructions to airflow. Avoid placing the cooling tower in enclosed spaces or near heat sources. Ensure easy access for maintenance and operation.

Foundation Requirements 🪨

Install on a stable and level foundation to prevent structural damage. Use anti-vibration mounts to reduce operational noise and vibration. Verify the foundation meets the weight capacity requirements.

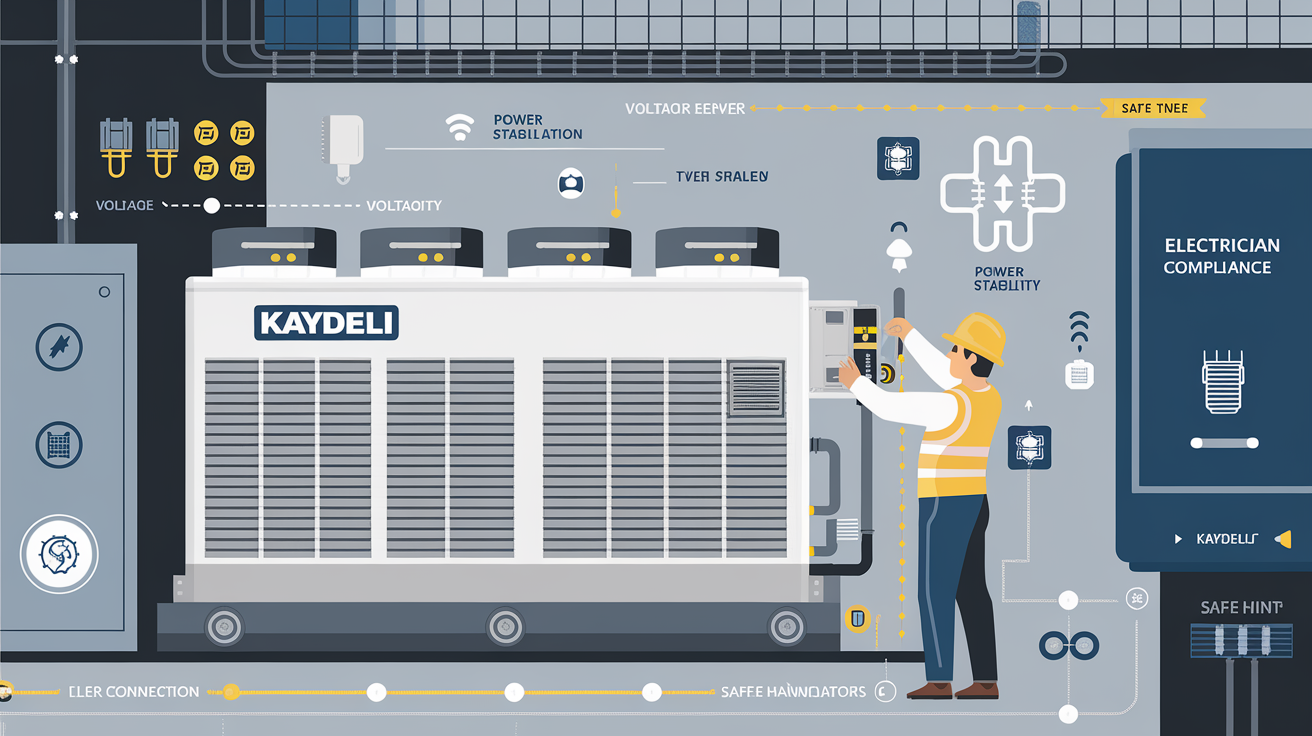

Water and Electrical Connections 💧⚡

Please properly connect the water inlet and outlet pipes to prevent leaks. Ensure electrical components are safely installed and grounded. Verify control systems and automation modules are functional.

Assembly and Alignment 🧩

Follow the manufacturer’s guidelines for assembling parts like fans, drift eliminators, and fill media. Align axial fans and motors to avoid imbalance and energy loss. Perform an initial operational test before full commissioning.

Práticas recomendadas de manutenção

Regular maintenance is essential for ensuring the optimal performance, energy efficiency, and longevity of Counterflow Cooling Towers. Key practices include routine cleaning of fill media, precise water treatment, fan and motor inspections, drift eliminator checks, and seasonal adjustments. With proactive monitoring and smart diagnostics, businesses can minimize downtime, reduce operational costs, and maintain consistent cooling efficiency. 🛠️💧✅

| Tarefa de manutenção | Descrição |

|---|---|

| Regular Cleaning 🧽 |

• Periodically clean the fill media to remove dirt, algae, and scale buildup. • Flush the water basin regularly to prevent sludge accumulation. |

| Water Treatment 💦⚗️ |

• Use water treatment chemicals to prevent scaling, corrosion, and biological growth. • Monitor pH levels and water hardness consistently. |

| Fan and Motor Inspection 🌬️⚙️ |

• Lubricate fan bearings and inspect motor alignment regularly. • Check for unusual vibrations or noise during operation. • Replace worn-out fan belts or damaged motor components promptly. |

| Drift Eliminator Check 🚫💧 |

• Ensure drift eliminators are intact and functioning properly. • Replace damaged eliminators to minimize water loss. |

| Seasonal Maintenance 📆❄️☀️ |

• Adjust fan speeds and water flow rates according to seasonal cooling demands. • Winterize the system in colder climates to prevent freezing damage. |

| Documentation and Monitoring 📑🔍 |

• Maintain a maintenance logbook for routine checks and repairs. • Use remote monitoring systems for real-time performance analysis. |

Why Proper Installation and Maintenance Matter ✅

-Maximized Efficiency: Reduces energy consumption and operational costs.

-Extended Lifespan: Prevents premature wear and tear of components.

-Stable Performance: Ensures consistent cooling output even during peak demand.

-Environmental Compliance: Proper water treatment reduces environmental impact.

-Cost Savings: Prevents expensive emergency repairs and downtimes.

Eficiência energética e custo-benefício

Counterflow Cooling Towers are designed to focus on eficiência energética e custo-benefício, making them a wise investment for industrial, HVAC, and commercial cooling applications. Below are the key factors contributing to their energy efficiency and financial advantages.

Optimized Airflow Design 🌬️🔄

With a 360° uniform air intake, energy-efficient axial fans, and Variable Speed Drives (VSD), our system delivers up to 30% energy savings by optimizing airflow and adjusting fan speeds based on real-time cooling needs.

Reduced Water Consumption 💦📉

With advanced drift eliminators, an optimized water distribution system, and intelligent make-up water control, our design conserves water resources and reduces operational costs through precise water management.

Efficient Heat Exchange Technology 🌡️🔄

With high-performance fill media, an efficient evaporative cooling process, and precise temperature control, our system ensures consistent cooling while minimizing energy expenditure.

Low Operational and Maintenance Costs 🛠️💰

With a simplified maintenance design, durable corrosion-resistant materials, and intelligent monitoring systems, our solution minimizes downtime and lowers long-term maintenance and replacement costs.

Suporte à marca e pós-venda

Regarding industrial and commercial cooling solutions, Kaydeli Square Cooling Towers stand out with their cutting-edge design, eficiência energéticae reliable performance. Below are the key reasons Kaydeli is the right decision for your cooling needs.

Por que escolher a Kaydeli?

Kaydeli stands out as a trusted leader in the cooling tower industry, delivering innovative solutions backed by decades of experience. Here’s why choosing Kaydeli ensures the best value for your investment:

Proven Expertise and Innovation

Backed by decades of experience, continuous R&D investment, and tailored solutions, we deliver reliable performance and future-ready cooling tower technologies for diverse industrial and commercial needs.

Global Presence and Reputation

Trusted worldwide for quality, reliability, and environmental responsibility, we serve diverse industries across regions and climates, delivering consistent excellence to thousands of satisfied clients.

Energy-Efficient and Sustainable Design

With optimized energy-saving designs, advanced drift eliminators, and environmentally friendly components, our systems reduce operational costs and carbon footprint while supporting sustainability goals.

Customizable Solutions

With flexible configurations, modular designs, and adaptability across industries, our solutions deliver maximum efficiency and cost-effectiveness tailored to your unique operational needs.

Suporte pós-venda abrangente

Kaydeli’s commitment doesn’t end with the sale – our after-sales support ensures long-term efficiency e customer satisfaction.

Assistência profissional para instalação

A orientação especializada durante a configuração garante que seu resfriador opere com eficiência desde o início.

Planos de manutenção personalizados

As programações de manutenção personalizadas ajudam a maximizar o desempenho do resfriador e a minimizar o tempo de inatividade.

Suporte técnico 24 horas por dia, 7 dias por semana

A equipe de suporte dedicada da Kaydeli está sempre disponível para resolver problemas prontamente, garantindo operações ininterruptas.

Serviços de garantia e reparo

Opções abrangentes de garantia protegem seu investimento, com serviços de reparo rápidos e eficientes.

Comentários de clientes e estudos de caso

Ouvir a opinião de outros usuários pode ser de grande valia ao selecionar o chiller certo. Aqui estão alguns destaques do feedback de clientes de vários setores que usam os resfriadores Kaydeli:

Global Plastics Corp.

Our production line requires consistent cooling under high heat loads. Kaydeli’s Flow Round Water Cooling Tower has been a game-changer—energy-efficient, low maintenance, and highly reliable. Downtime is no longer an issue!

GreenTech Corporate Tower

Maintaining comfortable indoor temperatures in our office building was a challenge until we switched to Kaydeli’s Flow Round Cooling Tower. It’s energy-efficient, quiet, and delivers stable performance even during peak summer months

National Energy Grid

Power plants demand precision cooling to avoid overheating critical equipment. Kaydeli’s cooling tower has delivered consistent results, even under heavy load conditions. Maintenance has also been hassle-free.