- Kaydeli

- Screw Type Chiller

Screw Type Chiller

Catalogy:Air Cooled Chillers

Determine the right cooling capacity for your setup by estimating kilowatt requirements per hour. 🤓

|

Cooling Capacity: -- kW

|

|

Basic Working Principle of Chillers

Chillers operate on a refrigerant cycle to provide efficient cooling by extracting heat from designated areas. This cycle involves four main stages:

Compression

Condensation

Expansion

Evaporation

This process enables chillers to provide consistent cooling in various industrial and commercial applications by continuously removing heat from the environment.

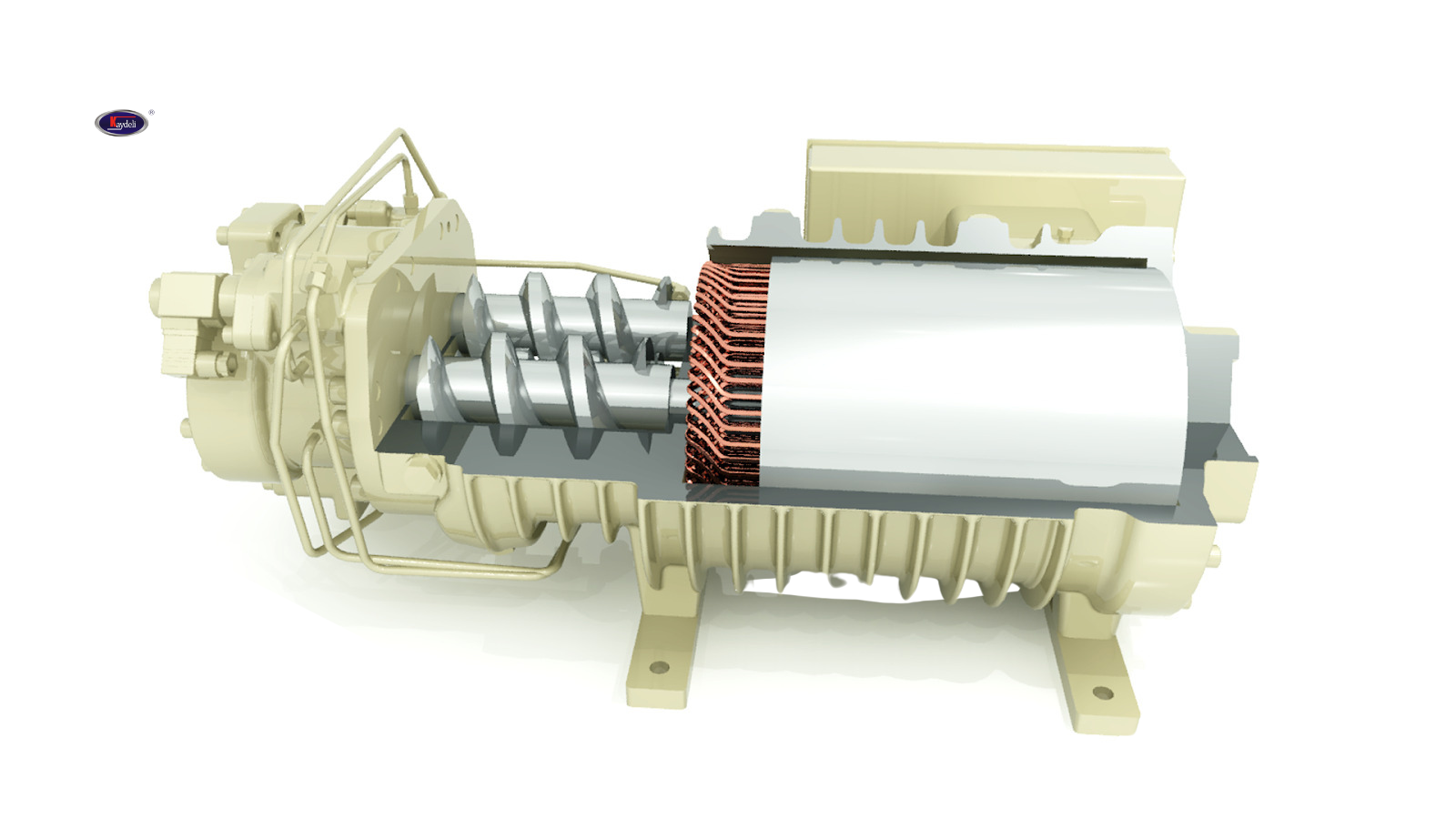

What Is the Screw Type Chiller

A Screw Type Chiller is a type of industrial chiller that uses a screw compressor, which operates with a unique rotary mechanism to compress refrigerant and achieve effective cooling. The screw compressor inside these chillers consists of two helical rotors (often called screws) that rotate together. As they turn, the refrigerant gas is drawn into the space between the rotors, compressed as the rotors move, and then pushed out at high pressure. This process efficiently compresses the refrigerant and provides consistent cooling for high-demand applications.

Key Characteristics of Screw-Type Chillers

High Capacity: Screw Type Chillers are known for handling large cooling loads, making them ideal for applications that require continuous, powerful cooling, such as data centers, large commercial buildings, and industrial processes.

Energy Efficiency: Although they consume significant power, screw compressors operate efficiently at high loads, and many models include variable speed options to optimize energy use when full capacity isn’t needed.

Continuous Operation: Screw compressors are designed for durability and continuous use, with fewer moving parts than reciprocating compressors, resulting in lower wear and maintenance requirements.

Quiet Operation: Compared to other high-capacity chillers, Screw Type Chillers are relatively quiet, which is beneficial for environments where noise reduction is essential.

Comparison with Other Types of Air-Cooled Chillers

Different air-cooled chillers—like Scroll, Piston, Screw, Low Temperature, Dual-Use, PCB, and Oil Cooling—offer specific cooling advantages. Scroll and Piston Chillers deliver versatile, quiet cooling for offices and factories, while other types are specialized for intense cooling needs or precision applications. The table below highlights each chiller type’s unique benefits.

| Chiller Type | Description | Best Use | Difference |

|---|---|---|---|

| Scroll and Piston Type Chillers | Efficient, versatile cooling with scroll or piston compressors. | Offices, hotels, factories. | Quiet operation with high-pressure cooling options. |

| Screw Type Chillers | Rotary screws for large-capacity, continuous cooling. | Data centers, large industrial facilities. | Higher capacity but more energy use and noise. |

| Low Temperature Chillers | Engineered for deep cooling at sub-zero temperatures. | Pharmaceuticals, chemical processing. | Designed for extreme cooling; Scroll/Piston for standard ranges. |

| Dual-Use Temperature Chillers | Switches between heating and cooling as needed. | Labs, testing facilities with variable temperature needs. | Offers both heating and cooling; Scroll/Piston are for cooling only. |

| PCB Industry Chillers | Precision cooling for printed circuit board manufacturing. | Electronics manufacturing, PCB production. | Exact temperature control, whereas Scroll/Piston are general-purpose. |

| Oil Cooling Chillers | Specialized to maintain optimal temperatures for machinery oils. | Metalworking, hydraulic systems. | Focused on oil cooling; Scroll/Piston focus on air cooling. |

Resources

Cooling Requirements

Cooling Capacity Needs

Selecting the appropriate cooling capacity is crucial to ensure the chiller meets the demands of your application efficiently. Screw Type Chillers are particularly suited for high-capacity cooling needs. Here’s how to calculate the required capacity:

| Step | Description |

|---|---|

| 1. Determine the Heat Load | Assess the total heat produced by your equipment or process. This can often be found in equipment specifications. |

| 2. Apply Cooling Formulas | Use formulas or industry calculators to convert heat load into cooling capacity, factoring in the desired temperature drop and area size. |

| 3. Choose Based on Capacity | Once the required kW or TR is determined, choose a chiller with sufficient capacity to handle your cooling load effectively. |

Choosing Screw Type Chillers for High-Demand Applications

Screw Type Chillers are optimized for applications with substantial, continuous cooling needs. Here are some scenarios where Screw Type Chillers are an ideal choice:

Industrial Facilities

For large-scale operations such as plastic injection molding, food processing, and chemical production, Screw Type Chillers provide robust cooling, reducing the risk of overheating and ensuring stable production conditions.

Commercial Buildings

In large commercial spaces like hotels, hospitals, and office buildings, Screw Type Chillers deliver effective climate control and adapt well to varying load demands.

Data Centers and IT Facilities

For facilities with servers and high-tech equipment, reliable and powerful cooling is crucial. Screw Type Chillers meet these demands with consistent, round-the-clock cooling, safeguarding equipment and maintaining operational integrity.

Temperature Requirements

Water Temperature Needs

The target water temperature for your application is an essential factor in choosing the right Screw Type Chiller. Screw Type Chillers are highly adaptable and can maintain specific temperatures for various processes, making them suitable for applications that require precise temperature control. Here’s how to determine the correct water temperature needs:

| Industry | Optimal Temperature Range | Purpose | Temperature Stability |

|---|---|---|---|

| Plastic Processing | 7°C to 15°C | Used primarily for mold cooling to enhance production efficiency, reduce cycle times, and minimize defects in molded products. | Maintaining a stable temperature is critical to avoid quality issues in molded parts and to ensure consistent production rates. |

| Food and Beverage Storage and Processing | 0°C to 5°C | Essential for preserving food freshness, controlling fermentation, and ensuring safe storage conditions. | Screw Type Chillers are effective in maintaining low, steady temperatures, preventing temperature fluctuations that could impact product quality or safety. |

| Chemical and Pharmaceutical Manufacturing | -5°C to 10°C | Used to control reaction temperatures, improve process stability, and prevent overheating in sensitive chemical and pharmaceutical operations. | Precise temperature control is essential to maintain consistent reaction rates and ensure product quality and safety in pharmaceutical environments. |

| Data Centers and IT Facilities | 15°C to 20°C | Provides consistent cooling to prevent overheating in high-tech equipment, servers, and data storage units. | Maintaining a stable temperature is crucial to avoid downtime or equipment failure, especially in high-density data centers. |

| HVAC Systems for Commercial Buildings | 5°C to 15°C for chilled water systems | Provides climate control across large spaces, ensuring a comfortable environment for occupants. | Screw Type Chillers allow for stable temperature regulation across varying ambient conditions, supporting energy efficiency and occupant comfort. |

Environmental Temperature Impact

The ambient environment where the chiller operates can significantly affect its efficiency. Screw Type Chillers are designed to perform across a range of temperatures, but high or low ambient temperatures can still impact performance.

| Factor | Impact | Considerations |

|---|---|---|

| Operating Efficiency | Chillers perform best within a specified ambient temperature range (e.g., air-cooled chillers at ≤35°C). Efficiency decreases if ambient temperatures exceed this range. | For ambient temperatures above 43°C, the chiller may enter overload, triggering a shutdown due to high condenser pressure and exhaust temperature. |

| Cooling Capacity Fluctuations | Cooling capacity decreases as ambient temperature rises due to increased condenser pressure. Evaporator pressure remains unchanged, reducing cooling efficiency. | Higher outlet temperatures can temporarily boost cooling capacity, but also increase energy consumption. Maintain appropriate outlet temperature in hot conditions. |

| Equipment Protection | High ambient temperatures can cause compressors to intake overheated vapor, potentially leading to equipment failure. | Modern chillers often include overheat protection systems that shut down the equipment under unsuitable conditions to prevent damage. |

| Maintenance Needs | Frequent maintenance may be required in high-temperature environments to ensure efficient operation. | Regularly clean condensers and check system pressure to sustain performance and prevent overheating. |

| Equipment Selection | Chillers need to be selected based on their design operating range, ensuring compatibility with expected environmental conditions. | Select a model rated for high temperatures if necessary, and place air-cooled chillers in ventilated areas away from direct sunlight or other heat sources. |

Installation and Maintenance

Installation Requirements

The target water temperature is a key factor in choosing the right chiller. Different applications require specific water temperatures to function optimally. Determining the precise cooling temperature needed for your equipment or process allows you to select a chiller that can consistently maintain that level, ensuring both efficiency and reliability. Scroll and Piston Type Chillers are available in models designed to support a range of water temperatures, making it easy to match your cooling needs.

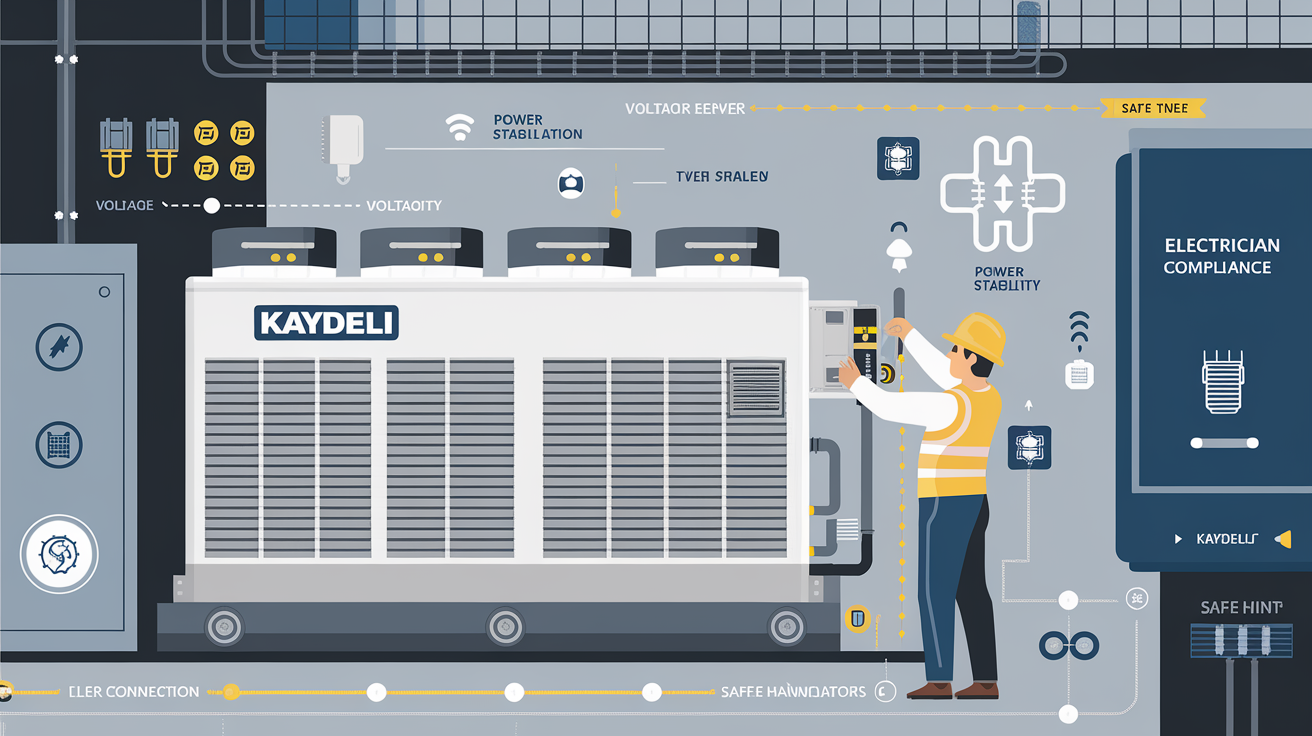

Space Requirements

Ensure there is sufficient space around the unit for ventilation and airflow. For air-cooled chillers, installing in a well-ventilated area is recommended, as this helps maintain efficiency and prevent overheating.

Surface and Positioning

Place the chiller on a stable, level surface to prevent vibrations during operation. Avoid areas with direct sunlight or proximity to other heat sources, as this can impact cooling efficiency.

Electrical Setup

Verify that the site meets the chiller’s electrical requirements, including voltage and power supply stability. Engage a certified electrician for safe and compliant electrical connections.

Maintenance Tips

Routine maintenance is key to preserving the efficiency and longevity of Screw Type Chillers. Here are essential maintenance steps:

| Maintenance Activity | Description |

|---|---|

| Regular Cleaning | Clean the condenser coils and air filters to prevent dust and debris buildup, which can impair cooling efficiency and increase energy consumption. |

| System Checks | Regularly check refrigerant levels, inspect for leaks, and monitor system pressures. Keeping an eye on these elements can help identify potential issues early and prevent costly repairs. |

| Seasonal Maintenance | In warmer seasons or high-demand environments, increase maintenance frequency to ensure reliable operation. Seasonal maintenance can include deep cleaning of condensers, inspecting electrical connections, and testing operational parameters. |

| Scheduled Professional Maintenance | Periodic professional maintenance, such as checking compressor health and calibrating controls, helps keep the chiller operating at peak efficiency. This service can also extend the chiller’s lifespan. |

Energy Consumption and Cost-Effectiveness

Energy Efficiency of Screw Type Air-Cooled Chillers

Screw Type Air-Cooled Chillers are engineered to handle substantial cooling loads while optimizing energy usage. Here are some key energy-related considerations.

Efficient Compression Mechanism

The screw compressor operates with a continuous rotary mechanism that allows for smooth and steady compression, reducing energy spikes and enabling efficient energy use. This results in a high energy-efficiency ratio (EER), especially under full load conditions.

Variable Capacity Options

Many Screw Type Chillers are equipped with variable-speed compressors, allowing the system to adjust its cooling capacity based on demand. This adaptability reduces power consumption during low-demand periods, lowering overall energy costs.

Seasonal Efficiency

Screw Type Chillers are built to perform well even in high ambient temperatures, but energy efficiency may vary by season. For environments with temperature fluctuations, choosing a model with a high seasonal energy efficiency ratio (SEER) ensures that energy use remains optimal throughout the year.

Balancing Initial Investment and Operational Costs

Investing in a Screw Type Chiller involves understanding both the upfront cost and long-term savings potential. Here’s what to consider.

Upfront Investment

Screw Type Chillers may have a higher initial cost due to their robust design and high cooling capacity. However, their energy-efficient operation can offset these costs over time, making them a cost-effective choice for high-demand environments.

Reduced Maintenance Costs

Due to fewer moving parts and lower wear, Screw Type Chillers often require less frequent maintenance than other compressor types. This helps lower operational costs and reduces the likelihood of unexpected repairs.

Long-Term Savings

The combination of energy efficiency, low maintenance requirements, and adaptability to variable cooling demands makes Screw Type Chillers a cost-effective option for long-term use. In high-demand settings, these chillers can significantly lower electricity bills and reduce the total cost of ownership over time.

Brand and After-Sales Support

Trusted Brand Reputation

When investing in a Screw Type Air-Cooled Chiller, choosing a reliable brand is key to ensuring product quality and performance. Kaydeli is known for its commitment to durability, efficiency, and innovation in chiller technology. Here’s why brand quality matters:

Proven Performance

Kaydeli chillers are designed to meet demanding industry standards, offering reliable and efficient performance across a range of applications.

Advanced Technology

Kaydeli integrates the latest in screw compressor technology and energy-saving features to optimize cooling efficiency and reduce operational costs.

Sustainable Practices

With a focus on eco-friendly refrigerants and efficient designs, Kaydeli chillers help reduce environmental impact, supporting customers’ sustainability goals.

Comprehensive After-Sales Support

Effective after-sales support ensures that customers receive ongoing assistance throughout the chiller’s lifespan. Kaydeli offers comprehensive customer support services, including

Installation Guidance

Professional installation support to help customers set up the chiller for optimal performance.

Maintenance Services

Scheduled maintenance programs tailored to the chiller’s operating conditions, minimizing downtime and extending equipment life.

Technical Assistance

A dedicated technical support team is available to troubleshoot issues and provide solutions, ensuring minimal disruption to operations.

Warranty Protection

Kaydeli provides robust warranty options that cover repairs or replacement in case of unexpected issues, giving customers peace of mind.

Customer Feedback and Case Studies

Hearing from other users can be invaluable when selecting the right chiller. Here are some highlights of customer feedback from various industries that use Kaydeli chillers:

Global Plastics Co

Kaydeli’s Screw Type Chillers have greatly improved our cooling efficiency. Their high capacity and stable performance allow us to maintain non-stop production without overheating concerns. This has directly led to a 10% increase in our production output, with downtime now minimized.

DataSecure Solutions

In our data center, cooling is essential to prevent server overloads, and Kaydeli’s Screw Type Chillers have proven exceptionally reliable. Even under heavy loads, they maintain low temperatures seamlessly. The chiller’s adaptability to varying demands has allowed us to reduce energy costs and operate more efficiently.

Skyline Hospitality Group

Our hotel guests rely on a comfortable, quiet environment, and Kaydeli’s Screw Type Chillers meet these needs perfectly. The energy efficiency has brought down our operating costs, while the low noise level enhances guest comfort. We’re pleased with the consistency and quality these chillers provide.