- Kaydeli

- Water Heat Source Steam Heat Pumps

Water Heat Source Steam Heat Pumps

Catalog:Bombas de calor Chillers

Determine a capacidade de resfriamento correta para sua configuração estimando os requisitos de quilowatts por hora. 🤓

|

Capacidade de resfriamento: --

|

|

Princípio de funcionamento simplificado das bombas de calor

As bombas de calor operam absorvendo o calor do ar, comprimindo-o para aumentar a energia, liberando o calor para uso e reciclando o refrigerante para aquecimento ou resfriamento contínuo.

Absorção de calor

Compressão

Liberação de calor

Expansão

What Are Water Heat Source Steam Heat Pumps?

Water Heat Source Steam Heat Pumps are advanced systems that use water as a renewable thermal energy source to generate steam for industrial and commercial applications. These pumps extract heat from water sources such as rivers, lakes, groundwater, or industrial waste heat and efficiently convert it into high-grade steam.

| Recurso | Descrição |

|---|---|

| Sustainable Energy Solution | Utilizes water as a renewable and consistent energy source, reducing reliance on fossil fuels. |

| High-Efficiency Steam Generation | Produces steam with minimal energy input, significantly improving operational efficiency compared to traditional boilers. |

| Operação ecologicamente correta | Emits lower greenhouse gases by leveraging renewable energy sources and reducing overall energy consumption. |

| Versatile Applications | Suitable for industries requiring precise and consistent steam production, including food processing, pharmaceuticals, textiles, and chemical manufacturing. |

| Wide Temperature Range | Capable of generating steam at temperatures up to 120°C or higher, depending on the application. |

| Aspecto | Traditional Steam Systems | Water Heat Source Steam Heat Pumps |

|---|---|---|

| Fonte de energia |

– Relies on fossil fuels like coal, oil, or natural gas. – Non-renewable, contributing to resource depletion and environmental degradation. |

– Utilizes renewable heat from water sources such as rivers, lakes, or industrial waste heat. – Reduces dependency on fossil fuels, making it more sustainable. |

| Efficiency |

– Lower overall efficiency due to energy loss during combustion and heat transfer. – Fixed output leads to energy waste during periods of reduced demand. |

– Significantly higher efficiency, often exceeding 300%. – Variable-speed compressors adjust output to match demand, minimizing energy waste. – Lower operational costs due to reduced energy consumption. |

| Impacto ambiental |

– High greenhouse gas emissions (CO2, NOx, and SOx). – Contributes to global warming and air pollution. – Increased regulatory pressures and compliance costs. |

– Little to no direct emissions by using renewable heat sources. – Incorporates low-GWP refrigerants for an eco-friendly footprint. – Compliant with global sustainability regulations. |

| Additional Advantages |

– Higher maintenance needs due to combustion processes. – Less adaptable to diverse temperature requirements. |

– Reduced maintenance costs due to fewer moving parts. – Flexible and customizable for various temperature needs. – Future-proof technology aligning with energy transition goals. |

Comparison of Water Heat Source Steam Heat Pumps and Other Heat Pumps

This table compares Water Heat Source Steam Heat Pumps with other heat pump types, including Air and Ground Source Heat Pumps. It highlights key differences in energy sources, efficiency, installation complexity, applications, environmental impact, and costs, providing a comprehensive overview to help users select the most suitable system for their needs.

| Recurso | Water Heat Source Heat Pumps | Other Heat Pumps (Air & Ground Source) |

|---|---|---|

| Fonte de energia |

- Extracts heat from water sources (rivers, lakes, groundwater, or industrial waste heat). - Provides stable thermal energy regardless of outdoor air temperature. |

- Air Source: Extracts heat from ambient air, performance decreases in extreme cold. - Ground Source: Extracts heat from underground, requires extensive drilling. |

| Efficiency |

- Highly efficient due to stable water temperatures. - Less affected by seasonal or weather variations. |

- Air Source: Efficiency drops in cold climates. - Ground Source: High efficiency but requires higher installation costs. |

| Installation Complexity |

- Requires access to water sources. - Installation complexity depends on water proximity and permits. |

- Air Source: Simple installation, suitable for urban areas. - Ground Source: Requires significant excavation or drilling, increasing costs. |

| Aplicativos |

- Ideal for industries needing consistent steam or heating (e.g., food processing, pharmaceuticals, textiles). - Suitable for district heating and industrial processes. |

- Air Source: Ideal for residential and commercial HVAC systems. - Ground Source: Best for long-term installations with available land space. |

| Impacto ambiental |

- Eco-friendly by using renewable water-based thermal energy. - Reduced greenhouse gas emissions and energy consumption. |

- Air Source: Lower emissions but efficiency varies with climate. - Ground Source: Low emissions but requires more resources for installation. |

| Cost |

- Moderate installation costs, depending on water accessibility. - Lower operational costs due to higher efficiency. |

- Air Source: Lower initial cost, higher operational cost in extreme climates. - Ground Source: High upfront cost with long-term savings. |

Recursos

Requisitos de aquecimento

Necessidades de capacidade de aquecimento

Understanding your specific heating requirements is essential to ensure optimal performance and efficiency when using a Water Heat Source Steam Heat Pump. Here’s a breakdown of how to determine your needs and choose the right system:

| Requisito | Detalhes |

|---|---|

| 🔥 Heat Demand |

- Identify process-specific heat needs (e.g., sterilization, drying). - Calculate heating load in kW or BTU based on facility size. - Examples: Food processing or chemical reactions requiring consistent heat. |

| 🌡️ Temperature Requirements |

- Define required steam temperatures (e.g., 80°C–120°C or higher). - Low temperatures suit district heating; high temperatures benefit industrial processes. |

| 🌊 Operational Environment |

- Ensure a reliable water source (e.g., rivers, lakes, industrial waste heat). - Consider water temperature stability for consistent heat extraction. - Suitable for regions with limited seasonal variations. |

| ⚡ Energy Efficiency Goals |

- Look for a system with a high Coefficient of Performance (COP). - Prioritize systems with low-GWP refrigerants to reduce carbon footprint. - Balance cost savings with environmental objectives. |

| 📏 System Sizing |

- Choose a model with a capacity slightly exceeding the calculated heating load. - Opt for modular systems to accommodate future expansion or variable demand. - Example: Textile factories with fluctuating production cycles. |

| 🏭 Industry Examples |

- **Textile Industry**: Steam at 80°C–100°C for dyeing and finishing. - **District Heating**: Low-pressure steam for urban heating systems. - **Chemical Industry**: High-temperature steam >100°C for distillation and reactions. |

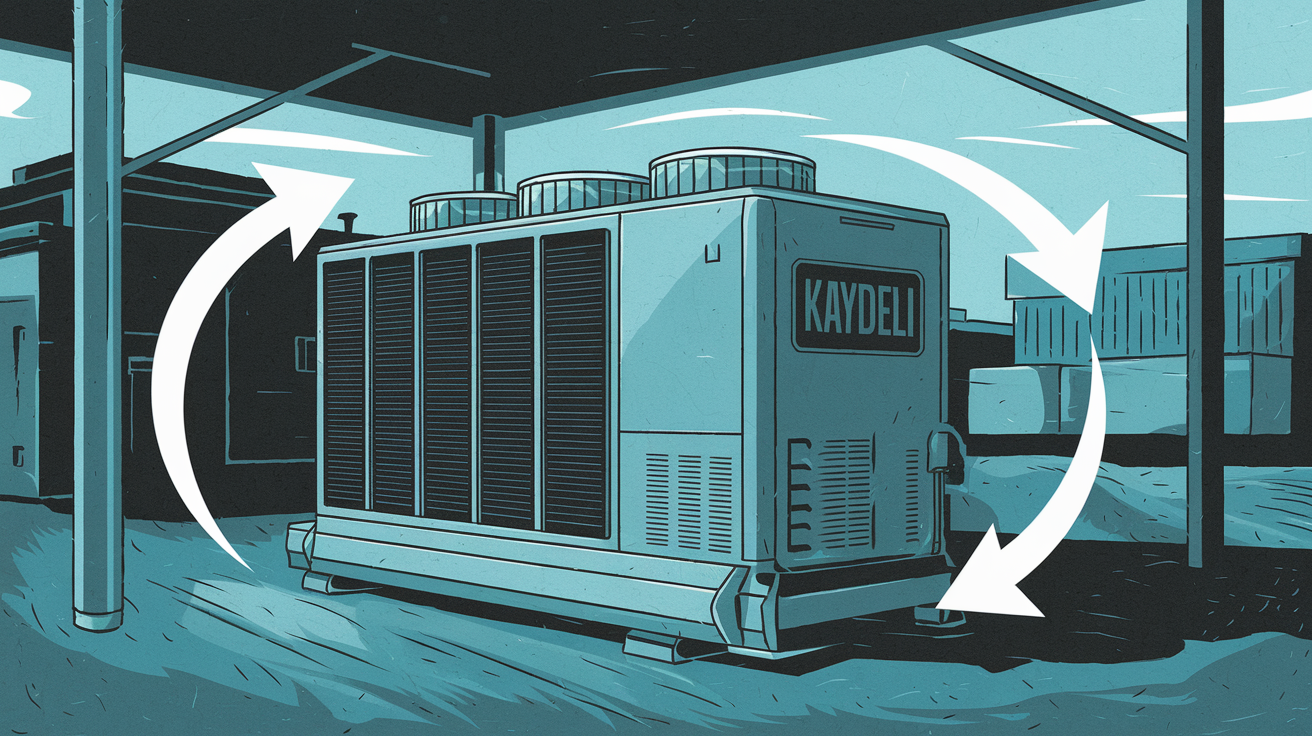

Where Water Heat Source Heat Pumps Excel

Water Heat Source Heat Pumps excel in a wide range of applications, offering superior efficiency, reliability, and eco-friendliness compared to traditional heating systems. Below are the key scenarios where these systems shine:

Processos industriais

-Aplicativos:

Steam-driven chemical reactions.

Distillation and drying processes in chemical, pharmaceutical, and food industries.

Pulp and paper production requiring consistent heating.

-Benefícios:

Provides precise temperature control for sensitive industrial processes.

Reduces operational costs by utilizing renewable water-based heat sources.

Sistemas de aquecimento distrital

-Aplicativos: Centralized heating for residential, commercial, and industrial buildings in urban and suburban areas.Supplying hot water and heating to multiple facilities.

-Benefícios:

Delivers cost-effective and environmentally friendly heating solutions.

Reduces dependency on fossil fuel-based heating systems.

Agricultural Applications

-Aplicativos:

Heating greenhouses to maintain optimal growth conditions for plants.

Humidity control and heat management in livestock facilities.

-Benefícios:

Promotes higher crop yields by maintaining stable temperatures.

Reduces heating costs for large-scale agricultural operations.

Renewable Energy Systems

-Aplicativos:

Integration with solar panels or geothermal systems to enhance renewable energy usage.

Hybrid systems for industrial and commercial buildings seeking sustainable solutions.

-Benefícios:

Maximizes energy efficiency by combining multiple renewable energy sources.

Supports environmental goals by reducing greenhouse gas emissions.

Temperature Requirements for Water Source Heat Pumps

Water Source Heat Pumps are highly adaptable to a range of temperature conditions due to their ability to extract thermal energy from water sources with stable temperatures. Below is an overview of their performance under various conditions and the requirements to consider:

| Aspecto | Detalhes |

|---|---|

| Optimal Temperature Range |

- Operates efficiently between 10°C e 25°C. - Groundwater maintains a stable range, ensuring year-round performance. |

| Cold Climate Performance |

- Works effectively even when water temperatures drop below 10°C. - Advanced systems maintain output with minimal efficiency loss. |

| High-Temperature Applications |

- Capable of generating steam up to 120°C or higher. - Ideal for processes requiring high-grade steam, such as food sterilization and chemical reactions. |

| Water Source Considerations |

- **Groundwater**: Consistent temperatures between 10°C–15°C. - **Surface Water**: Seasonal variations, ranging from 5°C–25°C. - **Industrial Waste Heat**: Stable and often above 30°C, improving efficiency. |

| Industry-Specific Temperature Needs |

Alimentos e bebidas: 60°C–120°C for sterilization and pasteurization. Fabricação de produtos químicos: 80°C–120°C for distillation and reactions. Indústria têxtil: 70°C-100°C para tingimento e acabamento. Aquecimento urbano: 40°C–80°C for urban heating systems. |

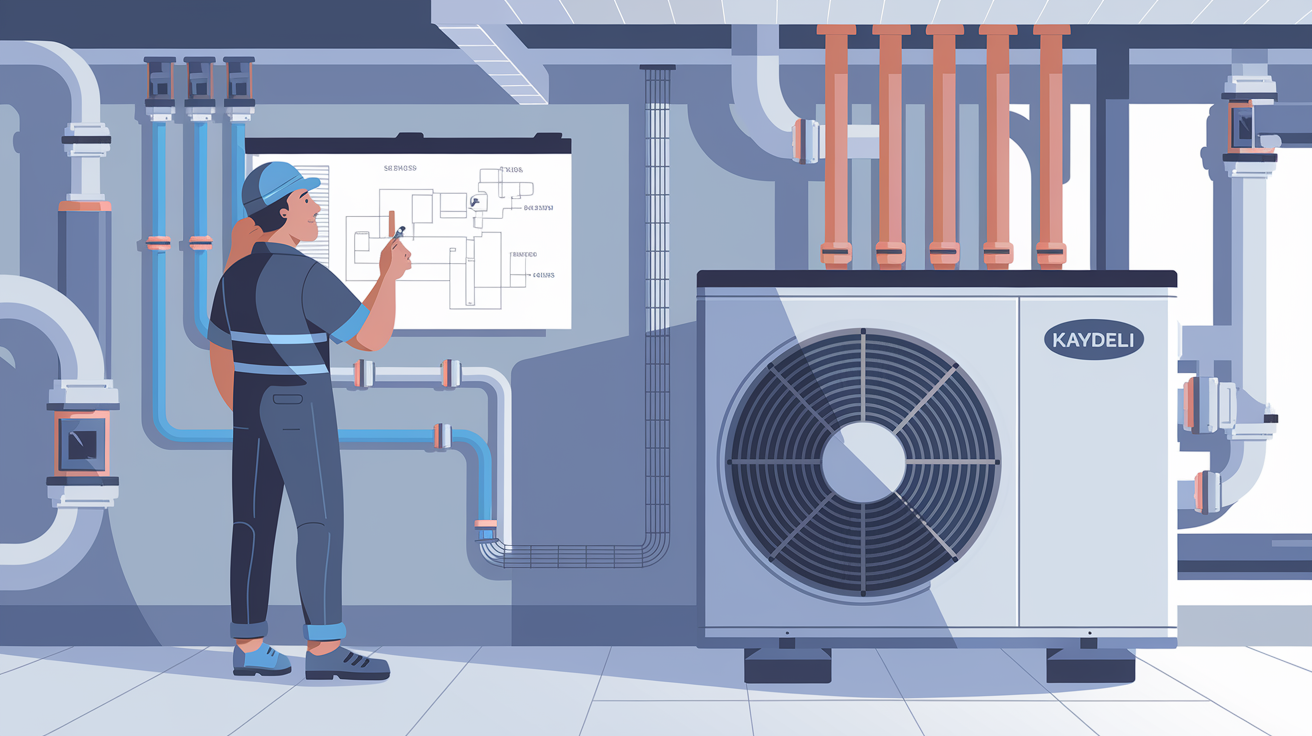

Instalação e manutenção

Proper installation and regular maintenance are crucial for ensuring that Water Heat Source Heat Pumps operate efficiently and reliably. This section highlights the key steps for installation and best practices for ongoing maintenance.

Diretrizes de instalação

🏗️ Site Preparation

Identify a consistent and reliable water source such as groundwater, lakes, rivers, or industrial waste heat. Ensure the site allows easy access for installation, water piping, and electrical connections.

🔧 Integração do sistema

Verify compatibility with existing heating systems, steam networks, or industrial processes. Professional installation is essential to correctly size the system and ensure proper heat extraction and flow.

Considerações sobre a qualidade da água

Analyze the water source for impurities, as high sediment or mineral content may require filtration systems to protect components like heat exchangers.

🛠️ Testes iniciais

After installation, could you test the heat pump system to ensure all components, such as compressors, pumps, and valves, operate correctly? Monitor initial heating performance, water flow rates, and steam output levels.

Práticas recomendadas de manutenção

A manutenção de rotina é fundamental para preservar a eficiência e a longevidade dos chillers tipo parafuso. Veja a seguir as etapas essenciais de manutenção:

| Tarefa de manutenção | Detalhes |

|---|---|

| 🧼 Regular Cleaning |

- Clean heat exchangers and filters to prevent scaling, clogging, or debris buildup that could impact efficiency. - Inspect and flush the water circuit periodically for smooth operation. |

| ⚙️ Component Inspections |

- Check compressors, refrigerant levels, and pumps regularly to identify wear and prevent unexpected breakdowns. - Inspect all pipes and valves for leaks or corrosion. |

| 🔍 System Monitoring |

- Use smart monitoring systems (if available) to track performance metrics such as steam output, energy consumption, and water temperature. - Set up performance alerts to address irregularities before they escalate. |

| 🧪 Water Treatment |

- Regularly test and treat the water source to avoid sediment buildup, scaling, or corrosion inside the system. - Utilize water softening or filtration systems if the water quality is subpar. |

| 📅 Manutenção profissional programada |

- Arrange for annual maintenance with certified technicians to ensure peak system performance. - Replace worn-out parts promptly, such as seals, valves, or pumps, to extend the lifespan of the system. |

Why Proper Installation and Maintenance Matter

1.Maximized Efficiency: Ensures consistent performance and optimal heat transfer.

2.Longer Lifespan: Prevents wear and tear, prolonging the system’s durability.

3.Economia de custos: Reduces energy consumption and lowers repair costs through preventive care.

4.Operational Reliability: Minimizes downtime for critical industrial processes or heating systems.

Eficiência energética e custo-benefício

Built for Energy Efficiency

Air Source Heat Pumps (ASHPs) are renowned for their ability to deliver high energy efficiency while supporting sustainability goals. Here’s how they excel in both areas:

High Energy Output

Kaydeli Water Source Heat Pumps achieve a Coefficient of Performance (COP) exceeding 3, meaning they produce more energy than they consume.

Variable-Speed Compressors

Adjust power output to match real-time demand, avoiding energy waste during partial loads.

Eco-Friendly Refrigerants

Modern low-GWP refrigerants minimize environmental impact while maintaining efficiency.

Eficiência sazonal

Consistent performance across varying climates ensures energy savings year-round, even in extreme weather conditions.

Long-Term Cost Benefits

Investing in Low Temperature Water Cooling Chillers provides significant financial advantages:

Lower Utility Bills

By operating efficiently, Kaydeli Water Source Heat Pumps significantly reduces energy expenses for homes and businesses.

Reduced Maintenance Costs

Durable designs and fewer moving parts ensure lower maintenance requirements over the unit’s lifespan.

Incentives and Rebates

Many regions provide financial support for energy-efficient installations, offsetting upfront investment.

Extended Lifespan

Designed for reliability, these systems offer a long operational life, reducing replacement costs.

Sustainability Advantages

Kaydeli Air Source Heat Pumps harness renewable energy from the air, reducing reliance on fossil fuels. With low-GWP refrigerants and hybrid compatibility, they offer high efficiency and eco-friendly performance, supporting sustainability goals.

Uso de energia renovável

Utilizes free, renewable heat from the air, reducing reliance on fossil fuels.

Design ecologicamente correto

Incorporates eco-conscious refrigerants and technologies to lower carbon footprints.

Integração híbrida

Effortlessly combines with solar panels or other renewable systems for even greater sustainability and savings.

Suporte à marca e pós-venda

Choosing the right system is about more than just technology—it’s also about trust, reliability, and ongoing support. Kaydeli’s Water Heat Source Steam Heat Pumps are backed by a globally recognized brand and industry-leading after-sales services, ensuring your investment delivers long-term value.

Por que escolher a Kaydeli?

A Kaydeli é líder global em soluções de aquecimento e resfriamento com eficiência energética, reconhecida por suas tecnologias inovadoras e pelo excepcional suporte ao cliente. Veja por que a Kaydeli se destaca:

Padrões de qualidade excepcionais

Os chillers da Kaydeli são construídos com materiais de nível industrial e tecnologia avançada, garantindo durabilidade e desempenho consistente em condições extremas.

Conhecimento específico do setor

Anos de experiência em diversos setores permitem que a Kaydeli forneça soluções personalizadas que atendem aos requisitos exclusivos de cada aplicação.

Compromisso com a sustentabilidade

A Kaydeli prioriza projetos ecologicamente corretos, integrando componentes com eficiência energética e refrigerantes ecologicamente corretos.

Confiabilidade comprovada

Com a confiança de empresas líderes em todo o mundo, os chillers Kaydeli fornecem consistentemente resfriamento preciso e eficiente para processos críticos.

Suporte pós-venda abrangente

A Kaydeli garante tranquilidade com um programa robusto de pós-venda projetado para maximizar o desempenho e a vida útil do produto

Assistência profissional para instalação

A orientação especializada durante a configuração garante que seu resfriador opere com eficiência desde o início.

Planos de manutenção personalizados

As programações de manutenção personalizadas ajudam a maximizar o desempenho do resfriador e a minimizar o tempo de inatividade.

Suporte técnico 24 horas por dia, 7 dias por semana

A equipe de suporte dedicada da Kaydeli está sempre disponível para resolver problemas prontamente, garantindo operações ininterruptas.

Serviços de garantia e reparo

Opções abrangentes de garantia protegem seu investimento, com serviços de reparo rápidos e eficientes.

Comentários de clientes e estudos de caso

Ouvir a opinião de outros usuários pode ser de grande valia ao selecionar o chiller certo. Aqui estão alguns destaques do feedback de clientes de vários setores que usam os resfriadores Kaydeli:

FreshFoods Processing Co.

Kaydeli’s system has been a game-changer for our operations. Energy costs are down, and steam output is stable, improving our production efficiency.

PharmaCare Solutions Ltd.

With Kaydeli’s steam heat pumps, we’ve achieved precise temperature control and significant energy savings. Their support team has been exceptional.

GlobalTextile Manufacturing

Kaydeli delivered a high-performance solution that drastically improved our production process while cutting costs.