- Kaydeli

- Low-Temperature Water Cooled Chillers

Low-Temperature Water Cooled Chillers

Catalog:Water Cooled Chillers

Determine a capacidade de resfriamento correta para sua configuração estimando os requisitos de quilowatts por hora. 🤓

|

Capacidade de resfriamento: --

|

|

Princípio básico de funcionamento dos resfriadores

Os chillers operam em um ciclo do refrigerante para proporcionar um resfriamento eficiente, extraindo o calor de áreas designadas. Esse ciclo envolve quatro estágios principais:

Compressão

Condensação

Expansão

Evaporação

Esse processo permite que os chillers forneçam resfriamento consistente em várias aplicações industriais e comerciais, removendo continuamente o calor do ambiente.

O que são os chillers de baixa temperatura?

Chillers de baixa temperatura são unidades de resfriamento especializadas projetadas para atingir e manter temperaturas extremamente baixas, normalmente abaixo de zero, para dar suporte a aplicações industriais e científicas que exigem controle preciso da temperatura. Diferentemente dos chillers padrão, que geralmente operam em faixas de temperatura padrão, os chillers de baixa temperatura são projetados para atingir e manter temperaturas tão baixas quanto -40°C ou até mais baixas, dependendo da aplicação. Esses chillers usam ciclos de refrigeração avançados e componentes especializados para lidar com as demandas de ambientes abaixo de zero.

| Recurso | Descrição |

|---|---|

| Faixa de temperatura ultrabaixa | Projetados para processos que exigem temperaturas muito abaixo de 0°C, os chillers de baixa temperatura são ideais para aplicações especializadas em que o resfriamento padrão é insuficiente. |

| Ciclo de refrigeração aprimorado | Esses chillers geralmente empregam ciclos de refrigeração de vários estágios ou em cascata, combinando diferentes mecanismos de resfriamento para atingir e manter temperaturas extremas com eficiência. |

| Alta precisão e estabilidade | Os chillers de baixa temperatura são capazes de realizar um controle preciso da temperatura, permitindo um resfriamento estável e ininterrupto mesmo em temperaturas muito baixas. |

Comparison with Other Types of Water-Cooled Chillers

Low Temperature Water Cooling Chillers are specifically engineered to handle ultra-low temperature requirements, setting them apart from standard water-cooled chillers like Scroll, Piston, Screw, and Centrifugal models. Here’s a detailed comparison:

| Recurso | Low Temperature Water Cooling Chillers | Scroll Chillers | Resfriadores de pistão | Screw Chillers | Centrifugal Chillers |

|---|---|---|---|---|---|

| Faixa de temperatura | Capable of cooling down to -30°C or lower, ideal for processes requiring sub-zero cooling. | Typically cools between 5°C and 15°C, suitable for moderate cooling demands. | Operates effectively from 5°C to 10°C; less efficient for ultra-low temperatures. | Maintains temperatures as low as 5°C but not optimized for sub-zero cooling. | Primarily used for cooling in the 7°C to 15°C range for large-scale systems. |

| Cooling Capacity | High; designed for extreme thermal loads associated with low temperatures. | Moderate; ideal for small to mid-sized applications. | High; suitable for industrial processes but less efficient at ultra-low temperatures. | Very high; handles large cooling loads but not specialized for extreme low temperatures. | Extremely high; built for massive facilities, not sub-zero requirements. |

| Compressor Type | Robust screw or piston compressors adapted for high-pressure, low-temperature performance. | Scroll compressors for efficient, low-vibration cooling at moderate temperatures. | Piston compressors for durable, heavy-duty cooling at standard industrial conditions. | Screw compressors for large-scale operations with variable loads. | Centrifugal compressors for energy-efficient cooling in large facilities. |

| Eficiência energética | Optimized for low-temperature processes, balancing efficiency and performance. | Energy-efficient for moderate cooling needs. | Moderate energy consumption for heavy-duty applications. | Highly efficient under partial loads but not designed for ultra-low temperatures. | Most efficient for large-scale cooling, not optimized for sub-zero temperatures. |

| Aplicativos | Chemical processing, pharmaceutical storage, food freezing, cold chain logistics. | Offices, data centers, small manufacturing facilities. | Plastic molding, heavy-duty industrial equipment, standard manufacturing processes. | HVAC for large buildings, industrial processes, chemical plants. | Power plants, airports, and other large-scale commercial or industrial facilities. |

| Cost | Higher upfront cost due to specialized components, offset by application-specific benefits. | Lower initial cost; affordable for moderate cooling needs. | Moderate cost with higher maintenance needs in demanding applications. | High initial cost, offset by efficiency in large-scale operations. | Very high initial and operational costs for large-scale applications. |

Recursos

Requisitos de resfriamento

Necessidades de capacidade de resfriamento

Determinar a capacidade de resfriamento correta é fundamental para garantir o desempenho ideal e a eficiência energética. Os requisitos de capacidade de resfriamento variam de acordo com fatores como carga de calor, temperatura desejada e tamanho da aplicação. Para ajudá-lo a fazer a escolha certa, incluímos uma tabela de cálculo simples nesta página. Essa ferramenta ajuda a estimar a carga de resfriamento (em kW ou TR) necessária para a sua configuração específica, orientando-o em relação ao modelo de chiller ideal para atender às suas demandas de resfriamento com eficiência.

| Recurso | Descrição | Benefit |

|---|---|---|

| Responsive Design | Adjusts to screen size for desktop and mobile users. | Ensures usability on all devices. |

| Consistent Styling | Uses predefined fonts, colors, and layouts. | Maintains brand consistency. |

| Enhanced Readability | Alternate row colors and adequate padding improve clarity. | Reduces visual strain. |

Os chillers do tipo Scroll e Pistão são versáteis e podem atender a uma variedade de demandas de resfriamento. Para necessidades de resfriamento moderadas a altas em aplicações de temperatura padrão, esses resfriadores oferecem desempenho confiável e eficiente em termos de energia.

Application Scenarios

Low Temperature Water Cooling Chillers are essential for industries that require precise cooling at sub-zero or near-zero temperatures. Their ability to maintain stable and consistent cooling makes them invaluable for a variety of specialized applications.

Manufatura industrial

-Aplicativos: Cooling chemical reactors, stabilizing volatile compounds, and managing exothermic reactions.

-Benefit: Ensures precise temperature control, enhancing reaction stability and product quality.

Electronic Component Testing

-Aplicativos: Thermal testing of semiconductors and electronic circuits in extreme conditions.

-Benefit: Ensures product reliability and performance under sub-zero temperatures.

Food and Beverage Industry

-Aplicativos: Freezing or cooling food products during production, packaging, and storage.

-Benefit: Maintains freshness and quality while meeting stringent food safety standards.

Industrial Freezing Systems

-Aplicativos: Cooling industrial molds, equipment, and processes requiring extreme thermal management.

-Benefit: Prevents overheating, ensuring efficiency and longevity of equipment.

Requisitos de temperatura

Precision Cooling for Extreme Conditions

Low Temperature Water Cooling Chillers are engineered to provide stable and precise cooling in demanding environments, ensuring consistent performance in applications requiring sub-zero temperatures.

| Recurso | Descrição |

|---|---|

| Advanced Temperature Regulation | Equipped with intelligent control systems, these chillers maintain precise temperatures, even under fluctuating loads. This ensures process reliability and product consistency. |

| Ultra-Low Temperature Performance | Designed to achieve and maintain temperatures as low as -30°C, they meet the demands of industries requiring extreme cooling precision. |

| Dynamic Cooling Adjustments | Real-time adjustments based on thermal loads prevent temperature overshoot or undershoot, ensuring optimal efficiency. |

| Robust Compressor Design | Specialized screw or piston compressors deliver consistent cooling performance, even in high-pressure, low-temperature environments. |

Benefits of Temperature Stability

O ambiente em que o chiller opera pode influenciar sua eficiência e capacidade de resfriamento, principalmente em climas extremos

| Benefit | Descrição |

|---|---|

| Enhanced Process Efficiency | Stable temperatures reduce variability in industrial processes, improving efficiency and output quality. |

| Reduced Product Waste | In applications like food processing and pharmaceuticals, precise cooling prevents spoilage and material degradation. |

| Increased Equipment Longevity | Consistent cooling minimizes wear and tear on machinery, extending its operational lifespan. |

| Energy Savings | Optimized temperature control prevents overcooling, reducing energy consumption and lowering operational costs. |

Instalação e manutenção

Proper Installation for Optimal Performance

A well-installed Low Temperature Water Cooling Chiller ensures efficient operation and long-term reliability. Follow these key installation steps:

Site Selection and Ventilation

Install the chiller in a well-ventilated area with stable ambient conditions. Ensure adequate space around the unit for easy access during maintenance. Place it near a reliable water source and cooling tower to optimize the water circulation loop.

Foundation and Stability

Set up the chiller on a flat, vibration-free surface to minimize operational instability. For large units, use reinforced concrete foundations to ensure secure placement.

Water Connection Setup

Use insulated pipes to prevent heat loss in the circulation system. Ensure all water connections are sealed properly to avoid leaks and maintain system efficiency.

Electrical Configuration

Verify that the electrical supply matches the chiller’s power requirements. Engage a certified electrician for proper wiring and installation to prevent power surges or damage.

System Testing and Calibration

Perform initial testing after installation to check water flow rates, refrigerant levels, and cooling performance. Adjust settings as needed for optimal operation.

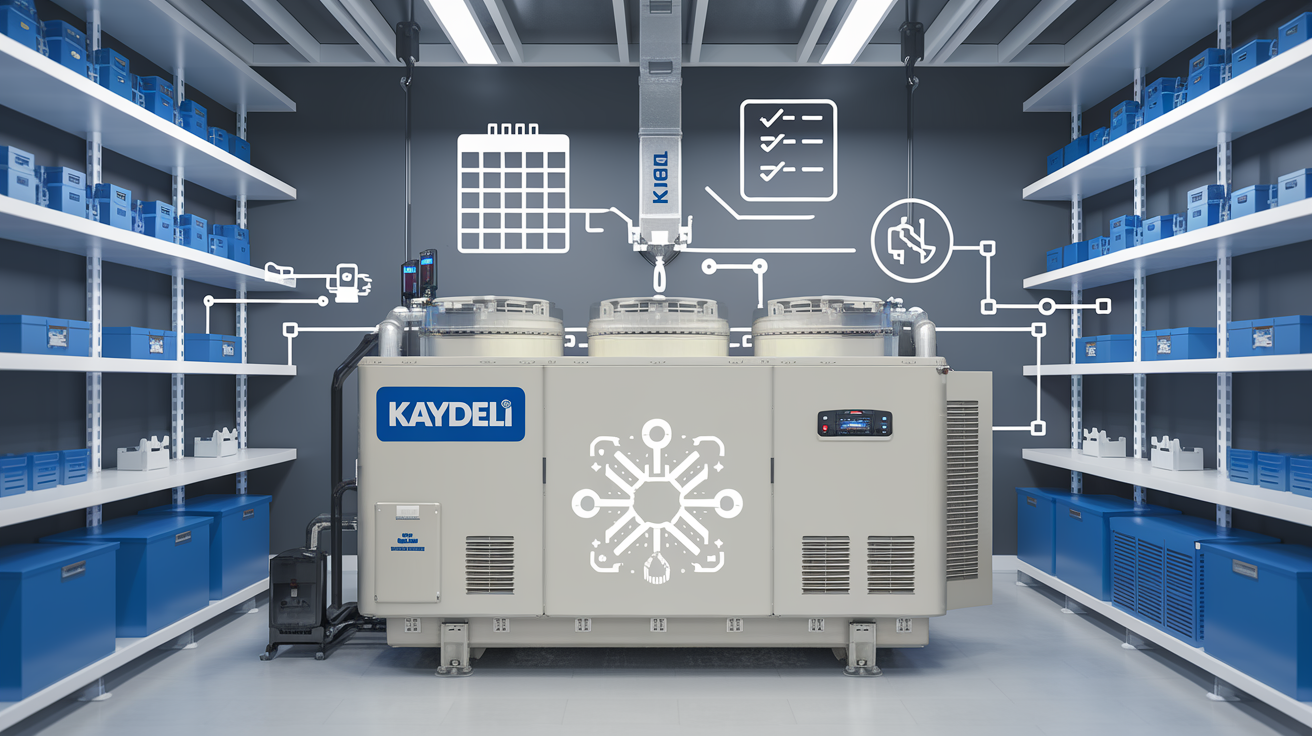

Routine Maintenance for Reliable Cooling

Low Temperature Water Cooling Chillers require regular maintenance to maintain their efficiency and extend their lifespan. Here’s a recommended plan:

| Task | Descrição |

|---|---|

| Clean Heat Exchangers Regularly | Remove dirt and scale from heat exchangers to maintain optimal heat transfer efficiency. For water-cooled systems, inspect and clean the cooling tower frequently. |

| Monitor Refrigerant Levels | Check refrigerant levels and pressure periodically to prevent reduced cooling performance or energy inefficiency. |

| Inspect and Maintain Compressors | Regularly inspect the screw compressor for wear or leaks. Ensure the compressor oil is at the proper level and replace it as recommended by the manufacturer. |

| Check Water Quality | Use treated water in the cooling system to prevent scaling and corrosion. Schedule regular water quality testing and maintenance to protect the chiller’s components. |

| Inspect Electrical Systems | Check for loose connections, worn cables, or electrical faults to ensure consistent power delivery. |

| Schedule Professional Maintenance | Arrange for periodic inspections by trained technicians to evaluate system performance, recalibrate controls, and replace aging components. |

Eficiência energética e custo-benefício

Built for Energy Efficiency

Kaydeli’s Low Temperature Water Cooling Chillers are designed to deliver precise cooling at sub-zero temperatures while minimizing energy consumption. Here’s how they achieve outstanding energy efficiency:

Optimized Heat Exchangers

High-efficiency heat exchangers maximize thermal transfer, reducing energy use while maintaining consistent cooling performance.

Advanced Compressor Technology

Equipped with high-performance screw or piston compressors that adjust cooling output based on demand, ensuring efficient operation even under partial loads.

Water-Cooled Design Advantage

Compared to air-cooled alternatives, water-cooled chillers are inherently more energy-efficient, especially for low-temperature applications.

Dynamic Control Systems

Intelligent control systems adapt in real time to thermal loads, avoiding energy waste during fluctuating operational requirements.

Long-Term Cost Benefits

Investing in Low Temperature Water Cooling Chillers provides significant financial advantages:

Extended Equipment Lifespan

Stable temperature control reduces wear and tear on both the chiller and connected systems, delaying costly replacements.

Custos de manutenção mais baixos

Durable components and optimized designs reduce the frequency and cost of repairs, ensuring reliable performance over time.

Reduced Energy Costs

Efficient cooling systems minimize electricity consumption, lowering operational expenses in facilities requiring continuous cooling.

Improved Productivity

By maintaining precise cooling, these chillers help prevent production losses, improving output quality and reducing waste.

Suporte à marca e pós-venda

Why Kaydeli is the Trusted Choice

Kaydeli is a global leader in industrial cooling solutions, offering innovative designs, robust performance, and reliable customer support. Here’s why Kaydeli’s Low Temperature Water Cooling Chillers are the top choice for demanding applications:

Padrões de qualidade excepcionais

Os chillers da Kaydeli são construídos com materiais de nível industrial e tecnologia avançada, garantindo durabilidade e desempenho consistente em condições extremas.

Conhecimento específico do setor

Anos de experiência em diversos setores permitem que a Kaydeli forneça soluções personalizadas que atendem aos requisitos exclusivos de cada aplicação.

Compromisso com a sustentabilidade

A Kaydeli prioriza projetos ecologicamente corretos, integrando componentes com eficiência energética e refrigerantes ecologicamente corretos.

Confiabilidade comprovada

Com a confiança de empresas líderes em todo o mundo, os chillers Kaydeli fornecem consistentemente resfriamento preciso e eficiente para processos críticos.

Suporte pós-venda abrangente

Kaydeli provides unparalleled after-sales support to ensure your investment delivers long-term value:

Assistência profissional para instalação

A orientação especializada durante a configuração garante que seu resfriador opere com eficiência desde o início.

Planos de manutenção personalizados

As programações de manutenção personalizadas ajudam a maximizar o desempenho do resfriador e a minimizar o tempo de inatividade.

Suporte técnico 24 horas por dia, 7 dias por semana

A equipe de suporte dedicada da Kaydeli está sempre disponível para resolver problemas prontamente, garantindo operações ininterruptas.

Serviços de garantia e reparo

Opções abrangentes de garantia protegem seu investimento, com serviços de reparo rápidos e eficientes.

Comentários de clientes e estudos de caso

Ouvir a opinião de outros usuários pode ser de grande valia ao selecionar o chiller certo. Aqui estão alguns destaques do feedback de clientes de vários setores que usam os resfriadores Kaydeli:

Biopharma Solutions

Kaydeli’s low-temperature chiller has been a game-changer for our vaccine production line. Its precise cooling ensures product stability and compliance with strict industry standards.

ChemPro Industries

With Kaydeli’s chiller, we’ve achieved consistent cooling for our reactors, resulting in a 15% increase in production efficiency. The energy savings are an added bonus.

Pharma Innovations

The Scroll Water Chiller has been a game-changer for our lab’s temperature-sensitive processes. It operates quietly and efficiently, allowing us to maintain precise conditions for quality control.