- Kaydeli

- Scroll or Piston Water Chiller

Scroll or Piston Water Chiller

Catalog:Water Cooled Chillers

Cooling Capacity: 9-190 KW

Determine a capacidade de resfriamento correta para sua configuração estimando os requisitos de quilowatts por hora. 🤓

|

Capacidade de resfriamento: --

|

|

Princípio básico de funcionamento dos resfriadores

Os chillers operam em um ciclo do refrigerante para proporcionar um resfriamento eficiente, extraindo o calor de áreas designadas. Esse ciclo envolve quatro estágios principais:

Compressão

Condensação

Expansão

Evaporação

Esse processo permite que os chillers forneçam resfriamento consistente em várias aplicações industriais e comerciais, removendo continuamente o calor do ambiente.

O que são resfriadores do tipo Scroll e Pistão?

Chillers do tipo scroll e pistão são dois chillers resfriados a ar específicos com designs de compressor distintos, cada um oferecendo benefícios exclusivos para diferentes requisitos de resfriamento.

Os compressores Scroll usam um mecanismo de rolagem em espiral para obter uma compressão de refrigerante suave e silenciosa, o que os torna ideais para ambientes em que o baixo nível de ruído é essencial. Veja como eles funcionam:

-O compressor consiste em um scroll fixo e um scroll móvel que gira dentro dele, comprimindo gradualmente o refrigerante a alta pressão.

-Esse design elimina o contato mecânico intenso, reduzindo o ruído e a vibração.

-Aplicações ideais: Os compressores Scroll são adequados para prédios de escritórios, hotéis e espaços públicos onde se prefere um sistema de resfriamento silencioso e estável.

Os compressores de pistão, também conhecidos como compressores alternativos, dependem de um mecanismo acionado por pistão que cria resfriamento de alta pressão, tornando-os ideais para aplicações de resfriamento exigentes. Veja o funcionamento deles:

-O compressor de pistão usa pistões dentro de cilindros, semelhante a um motor, para comprimir o refrigerante com grande força.

-Esse design permite altas taxas de compressão, proporcionando um resfriamento mais potente para aplicações intensivas.

-Aplicações ideais: Os compressores de pistão são comumente usados em ambientes industriais, laboratórios e fábricas, onde a alta potência de resfriamento é essencial.

Principais diferenças entre os compressores Scroll e de pistão

-Nível de ruído: Os compressores Scroll oferecem uma operação mais silenciosa e são adequados para ambientes sensíveis a ruídos.

-Potência de resfriamento: Os compressores de pistão oferecem maior capacidade de resfriamento e pressão, o que os torna ideais para aplicações industriais que exigem resfriamento intenso.

Differences Between Scroll and Piston Compressors

Scroll and Piston Water Chillers are distinguished by their compressor technology, each offering unique features and advantages suited to different applications. When compared to other types of water-cooled chillers, such as screw and centrifugal models, these chillers stand out in specific ways.

| Recurso | Compressores Scroll | Compressores de pistão | Screw Compressors | Centrifugal Compressors |

|---|---|---|---|---|

| Working Mechanism | Interlocking spiral scrolls compress refrigerant smoothly. | Piston motion in cylinders compresses refrigerant. | Rotary screws compress refrigerant continuously. | Rotating impeller compresses refrigerant using centrifugal force. |

| Noise and Vibration | Low; suitable for quiet environments. | Moderate; handles industrial conditions. | Moderate; stable for continuous use. | Low; ideal for large-scale, quiet operations. |

| Cooling Capacity | Moderate; ideal for small to mid-sized applications. | High; handles demanding industrial loads. | Very high; suitable for large-scale facilities. | Extremely high; used in massive facilities like power plants. |

| Eficiência energética | High for moderate cooling demands. | Moderate; durable for heavy-duty use. | High; optimized for continuous operations. | Very high; excellent for large-scale efficiency. |

| Aplicativos | Offices, labs, small-scale industries. | Heavy-duty industries, chemical plants, plastic molding. | Large factories, manufacturing facilities. | Power plants, large commercial buildings. |

Recursos

Requisitos de resfriamento

Necessidades de capacidade de resfriamento

Determinar a capacidade de resfriamento correta é fundamental para garantir o desempenho ideal e a eficiência energética. Os requisitos de capacidade de resfriamento variam de acordo com fatores como carga de calor, temperatura desejada e tamanho da aplicação. Para ajudá-lo a fazer a escolha certa, incluímos uma tabela de cálculo simples nesta página. Essa ferramenta ajuda a estimar a carga de resfriamento (em kW ou TR) necessária para a sua configuração específica, orientando-o em relação ao modelo de chiller ideal para atender às suas demandas de resfriamento com eficiência.

| Etapa | Descrição |

|---|---|

| 1. Determinar a carga térmica | Avalie o calor total produzido por seu equipamento ou processo. Isso geralmente pode ser encontrado nas especificações do equipamento. |

| 2. Aplicar fórmulas de resfriamento | Use fórmulas ou calculadoras do setor para converter a carga térmica em capacidade de resfriamento, levando em consideração a queda de temperatura desejada e o tamanho da área. |

| 3. Escolha com base na capacidade | Depois que o kW ou TR necessário for determinado, escolha um chiller com capacidade suficiente para lidar com a carga de resfriamento de forma eficaz. |

Os chillers do tipo Scroll e Pistão são versáteis e podem atender a uma variedade de demandas de resfriamento. Para necessidades de resfriamento moderadas a altas em aplicações de temperatura padrão, esses resfriadores oferecem desempenho confiável e eficiente em termos de energia.

Application Scenarios

Scroll and Piston Water Chillers are versatile cooling solutions designed to meet the specific needs of various industries. Their ability to provide precise and efficient cooling makes them indispensable in several applications.

Manufatura industrial

-Scroll Chillers: Suitable for small to mid-scale operations, such as light manufacturing and tool cooling.

-Resfriadores de pistão: Ideal for heavy-duty equipment like hydraulic presses, injection molding machines, and extrusion lines.

-Benefit: Maintains consistent equipment temperatures, ensuring efficient operation and reducing downtime.

Plastic and Rubber Processing

-Scroll Chillers: Used for mold temperature control in smaller-scale production.

-Resfriadores de pistão: Handles larger-scale operations, providing cooling for molds and machinery in high-output facilities.

-Benefit: Ensures uniform product quality by stabilizing mold and machinery temperatures.

Food and Beverage Industry

-Scroll Chillers: Perfect for refrigeration and small-scale storage systems.

-Resfriadores de pistão: Suitable for larger-scale operations, such as cooling water for brewing, dairy, or food processing.

-Benefit: Maintains product freshness by providing precise temperature control for refrigeration systems.

Sistemas HVAC

-Scroll Chillers: Common in small to mid-sized commercial buildings, providing efficient cooling for offices, retail spaces, and schools.

-Resfriadores de pistão: Used in large commercial or industrial HVAC systems where higher cooling capacities are required.

-Benefit: Creates comfortable indoor environments while optimizing energy consumption.

Temperature Control and Stability

Maintaining Optimal Water Temperatures

Scroll and Piston Water Chillers are designed to provide precise and stable temperature control, ensuring the efficiency and reliability of industrial and commercial processes. Their ability to maintain consistent water temperatures is critical for applications where even slight fluctuations can compromise performance.

| Recurso | Descrição |

|---|---|

| Advanced Temperature Control Systems | Both Scroll and Piston Water Chillers are equipped with smart control systems that monitor and regulate water temperatures in real time. This ensures consistent cooling performance even under varying load conditions. |

| High Precision for Sensitive Applications |

Scroll Chillers: Offer precise temperature control with minimal fluctuations, ideal for applications like laboratories and data centers where stability is crucial. Piston Chillers: Deliver robust cooling for processes with higher thermal loads, ensuring reliable performance even in demanding industrial environments. |

| Wide Operating Range | Capable of maintaining water temperatures from as low as 5°C to as high as 30°C, making these chillers versatile for a range of cooling needs across different industries. |

| Rapid Response to Temperature Changes | Both types of chillers respond quickly to changes in cooling demand, minimizing downtime and preventing thermal stress on equipment. |

Benefits of Stable Water Temperatures

| Benefit | Descrição |

|---|---|

| Improved Equipment Performance | Consistent cooling prevents overheating, ensuring that machinery operates at peak efficiency and reducing wear and tear on components. |

| Enhanced Product Quality | In processes like plastic molding and chemical production, stable temperatures improve product consistency and reduce defects caused by temperature variations. |

| Eficiência energética | By maintaining precise temperatures, Scroll and Piston Chillers minimize energy waste, lowering operational costs while maintaining performance. |

| Prolonged Equipment Lifespan | Preventing temperature fluctuations reduces mechanical stress, extending the lifespan of both the chiller and connected equipment. |

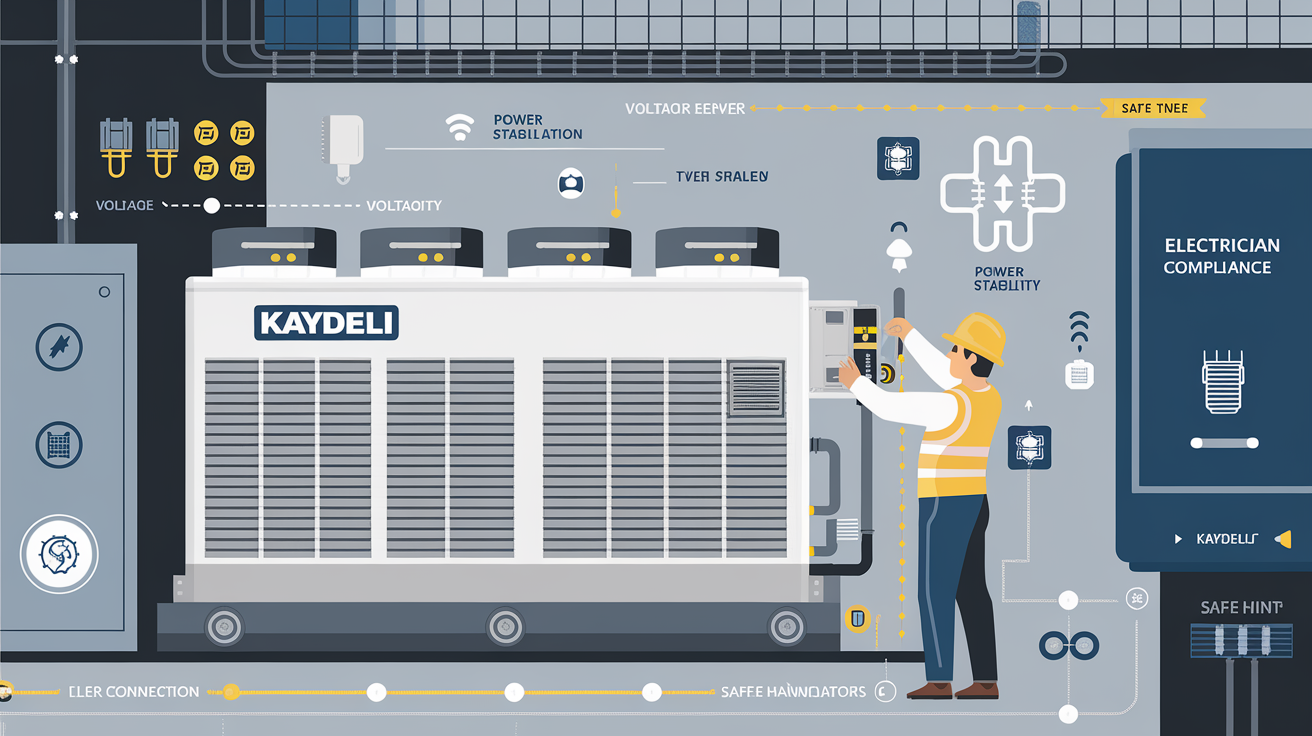

Instalação e manutenção

Installation Requirements for Optimal Performance

Proper installation is essential to maximize the efficiency and reliability of Scroll or Piston Water Chillers. Here are key considerations:

Requisitos de espaço

Place the chiller in a well-ventilated area to ensure proper heat dissipation and avoid overheating. Water-cooled chillers should also be installed near a stable water supply to optimize efficiency.

Superfície e posicionamento

Install the chiller on a level, vibration-free surface to prevent operational instability. A stable foundation protects internal components and ensures consistent cooling performance.

Configuração elétrica

Verify that the electrical supply meets the chiller’s power requirements. A licensed electrician should handle wiring and connections to prevent surges or electrical disruptions.

Maintenance Tips for Longevity and Efficiency

Routine maintenance is critical to keep your Scroll or Piston Water Chiller operating at peak performance. Here’s a recommended maintenance plan:

| Task | Descrição |

|---|---|

| Regular Cleaning | Clean water filters, heat exchangers, and evaporators to prevent buildup of dirt or scale, which can reduce cooling efficiency. For water-cooled systems, inspect and clean cooling towers or water supply lines regularly. |

| Monitor Refrigerant Levels | Check refrigerant levels periodically to ensure the system operates efficiently. Low refrigerant levels can lead to reduced cooling capacity and higher energy consumption. |

| Inspect and Replace Worn Components | Regularly inspect critical components like compressors, valves, and pumps for wear or damage. Replace any parts showing signs of deterioration to avoid breakdowns. |

| Water Quality Management | Ensure that the water used in the cooling system is clean and free from contaminants. Treat water to prevent scaling and corrosion in the heat exchangers. |

| Professional Maintenance | Schedule regular servicing by trained professionals to perform thorough system inspections, recalibrate controls, and ensure all components are functioning optimally. |

Eficiência energética e custo-benefício

Designed for Energy Efficiency

Kaydeli’s Scroll and Piston Water Chillers are engineered with energy-saving features to provide optimal cooling while minimizing energy consumption. Here’s how they achieve outstanding efficiency:

Efficient Heat Transfer

High-performance heat exchangers maximize cooling efficiency by ensuring optimal heat transfer. This reduces the workload on compressors, lowering energy consumption.

Advanced Compressor Technology

Scroll Compressors provide energy-efficient cooling for moderate demands, while Piston Compressors deliver powerful, efficient cooling for heavy-duty applications.

Smart Temperature Control

Equipped with advanced control systems, these chillers adapt cooling output based on real-time demand. This reduces unnecessary energy use during low-demand periods, improving overall efficiency.

Optimized for Water-Cooled Systems

Water-cooled designs use less energy compared to air-cooled alternatives, especially in environments with high cooling demands. This design makes them particularly cost-effective for industrial and commercial applications.

Long-Term Cost Benefits

Investing in Scroll or Piston Water Chillers provides significant cost savings over their lifespan. Here’s how:

Reduced Maintenance Expenses

Durable components and optimized designs minimize wear and tear, lowering the frequency and cost of repairs.

Lower Operational Costs

Energy-efficient compressors and heat exchangers reduce electricity bills, especially in facilities that require continuous operation.

Extended Equipment Lifespan

Stable temperature control reduces mechanical stress on the chiller and connected equipment, prolonging their operational life and delaying costly replacements.

Improved Productivity

Reliable cooling reduces downtime, allowing facilities to maintain consistent production schedules and meet operational targets.

Suporte à marca e pós-venda

Trust in Kaydeli’s Expertise

Kaydeli is a global leader in industrial cooling solutions, known for its innovative designs, durable products, and commitment to customer satisfaction. Here’s why Kaydeli’s Scroll or Piston Water Chillers are the preferred choice for industrial and commercial applications:

Unmatched Quality Standards

Kaydeli chillers are built with premium materials and cutting-edge technology, ensuring reliable and long-lasting performance under demanding conditions.

Conhecimento específico do setor

With years of experience in diverse industries, Kaydeli provides tailored cooling solutions to meet unique operational requirements.

Compromisso com a sustentabilidade

Kaydeli integrates energy-efficient components and environmentally friendly refrigerants, helping businesses achieve sustainability goals.

Suporte pós-venda abrangente

Kaydeli ensures peace of mind for its customers by offering a robust after-sales support system, designed to maximize chiller performance and longevity:

Assistência profissional para instalação

Expert guidance during installation ensures the chiller operates efficiently from day one, reducing setup errors and optimizing performance.

Planos de manutenção personalizados

Tailored maintenance schedules help keep the chiller in peak condition, minimizing downtime and ensuring consistent performance.

Suporte técnico 24 horas por dia, 7 dias por semana

Kaydeli’s dedicated support team is available around the clock to resolve any issues quickly, ensuring minimal operational disruptions.

Serviços de garantia e reparo

Comprehensive warranty options protect your investment, with prompt repairs or replacements to keep operations running smoothly.

Comentários de clientes e estudos de caso

Ouvir a opinião de outros usuários pode ser de grande valia ao selecionar o chiller certo. Aqui estão alguns destaques do feedback de clientes de vários setores que usam os resfriadores Kaydeli:

PolyTech Plastics

Kaydeli’s Piston Water Chiller has significantly improved the cooling consistency in our injection molding process. We’ve seen a 20% reduction in defects and smoother operation overall.

FreshBev Co.

We use Kaydeli’s Piston Chiller for cooling in our bottling line, and it’s been incredibly reliable, even during peak production times. Energy savings have also exceeded expectations.

Pharma Innovations

The Scroll Water Chiller has been a game-changer for our lab’s temperature-sensitive processes. It operates quietly and efficiently, allowing us to maintain precise conditions for quality control.