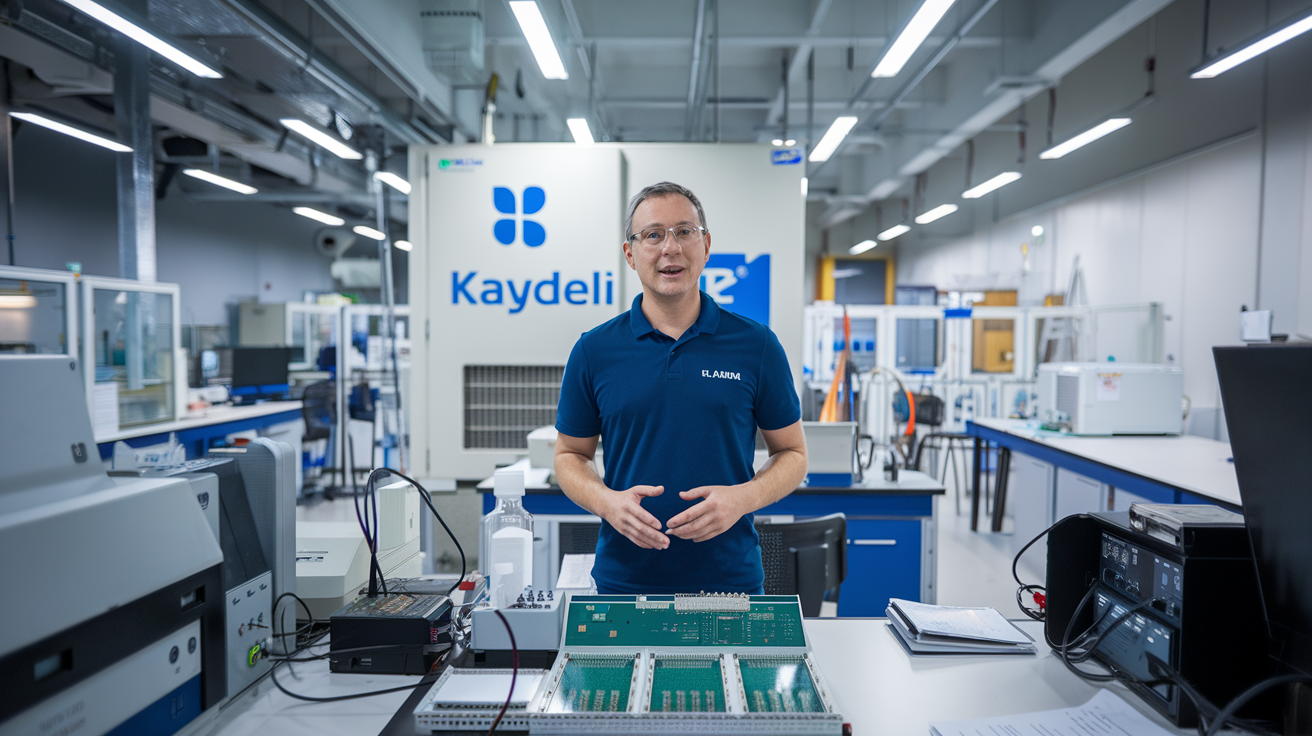

- Kaydeli

- PCB Industry Chillers

PCB Industry Chillers

Catalogy:Air Cooled Chillers

Determine the right cooling capacity for your setup by estimating kilowatt requirements per hour. 🤓

|

Cooling Capacity: --

|

|

Basic Working Principle of Chillers

Chillers operate on a refrigerant cycle to provide efficient cooling by extracting heat from designated areas. This cycle involves four main stages:

Compression

Condensation

Expansion

Evaporation

This process enables chillers to provide consistent cooling in various industrial and commercial applications by continuously removing heat from the environment.

What Are PCB Industry Chillers?

PCB Industry Chillers are specialized cooling units designed to meet the precise thermal management needs of PCB (Printed Circuit Board) manufacturing. PCB production involves a series of temperature-sensitive processes—such as soldering, etching, and laminating—where even slight temperature fluctuations can compromise the integrity of the circuit boards. PCB Industry Chillers maintain a stable temperature for cooling fluids, ensuring these critical processes run smoothly without risking damage to the components or affecting production quality.

| Feature | Description |

|---|---|

| Temperature Stability | Maintains consistent cooling throughout the PCB manufacturing process to support precision and quality control. |

| Process Support | Controls temperatures in systems that indirectly cool various stages of PCB production, helping prevent thermal stress on circuit boards and components. |

| Precision Control | Provides accurate temperature adjustments to match the unique demands of each stage in PCB production, minimizing defects and ensuring a higher-quality end product. |

Comparison with Other Types of Air-Cooled Chillers

PCB Industry Chillers have unique design features and performance characteristics that set them apart from general-purpose air-cooled chillers:

| Feature | PCB Industry Chillers | Other Air-Cooled Chillers |

|---|---|---|

| Precision Temperature Control | Engineered to provide highly precise temperature control, often within ±0.1°C, to prevent thermal stress that could compromise electronic components. | Typically used for broader applications, such as HVAC or general manufacturing cooling, where precision is less critical. |

| High Thermal Stability | Designed to maintain steady temperatures over long production cycles, helping prevent temperature fluctuations that could lead to quality issues in PCB production. | May be less suited to environments where strict temperature stability is required, making them less ideal for applications like PCB manufacturing. |

| Lower Operating Noise | Often built with noise-reducing features to meet the quieter environment requirements common in electronics manufacturing. | Noise control may be less of a priority, especially in industrial settings where ambient noise is expected. |

| Energy Efficiency in High-Demand Processes | Optimized for energy efficiency in continuous, high-precision operations typical of PCB production, maintaining cooling without excess power consumption. | While energy-efficient, they are generally not optimized for the extended, high-stability demands found in PCB manufacturing. |

| Dedicated Application Focus | Specifically tailored for PCB and electronics manufacturing, handling the unique thermal demands of sensitive components and preventing quality issues from minor temperature changes. | Broadly applicable across many industries, focusing on cooling efficiency for diverse applications but lacking the targeted design for precision electronics manufacturing. |

Resources

Cooling Requirements

Determining Cooling Capacity for PCB Manufacturing

In PCB manufacturing, precise cooling is crucial to maintain product quality and prevent thermal stress on components. Here’s how to assess the cooling requirements for PCB Industry Chillers:

| Step | Description |

|---|---|

| Evaluate the Heat Load | Identify the total heat generated during PCB processes, such as soldering and etching. This heat load is typically measured in kilowatts (kW) or tons of refrigeration (TR). In high-output facilities, continuous cooling is often needed to manage the accumulated heat effectively. |

| Consider Production Scale and Temperature Sensitivity | Determine the scale of your production and the temperature sensitivity of your PCB materials. For instance, high-frequency PCBs used in advanced electronics require tighter temperature control to avoid performance issues. This sensitivity informs the chiller’s capacity requirements, as smaller tolerance levels may require higher capacity or more frequent cooling. |

| Select Capacity Based on Process Demand | Use industry-standard formulas to convert the heat load and target temperature into the required cooling capacity (kW or TR) for PCB production. Consulting a cooling expert can also help ensure precise calculations tailored to PCB processes, reducing the risk of temperature fluctuations that can affect production quality. |

When to Use PCB Industry Chillers

Screw Type Chillers are optimized for applications with substantial, continuous cooling needs. Here are some scenarios where Screw Type Chillers are an ideal choice:

Cooling Production Equipment

PCB manufacturing involves equipment like soldering machines, pick-and-place machines, and laminators, which generate significant heat during operation. Excessive temperatures can impact equipment performance and PCB quality. PCB Industry Chillers provide cooling to these systems, maintaining optimal temperatures for stable, efficient operation. By circulating cooled water, chillers help prevent overheating, ensuring that production equipment performs reliably over extended periods.

Controlling Process Temperatures

Certain PCB manufacturing steps, such as coating, exposure, and developing, require precise temperature control to maintain material properties and process consistency. PCB Industry Chillers indirectly support these processes by supplying stable cooling water, which helps maintain the required environmental conditions. This temperature control contributes to product uniformity and increases the yield of high-quality PCBs.

Thermal Management for High-Power Density

With the growing integration of electronic components, PCB designs now have higher power densities, making effective thermal management critical. PCB Industry Chillers provide an indirect cooling solution through circulating water, which helps manage the temperature of PCBs and their components. This cooling prevents performance degradation or damage caused by excessive heat, ensuring product reliability even with increased component density.

Deep Cooling Technology for High-Performance Applications

In some advanced applications, such as high-performance computing systems, deep cooling technology is required to enhance the efficiency and reliability of PCBs. PCB Industry Chillers use refrigerant phase-change technology to absorb large amounts of heat, creating a low-temperature environment that optimizes the performance of electronic components. This deep cooling method is particularly useful for power-intensive electronics where heat management is critical.

Temperature Precision and Stability

Importance of Precise Temperature Control in PCB Manufacturing

In PCB manufacturing, maintaining stable and precise temperatures is essential to achieve consistent product quality and prevent damage to sensitive components. PCB Industry Chillers provide accurate temperature regulation, ensuring that all process stages operate under optimal conditions. Here’s how temperature precision and stability benefit PCB production:

| Benefit | Description |

|---|---|

| Enhanced Process Consistency | Many steps in PCB production, such as soldering, coating, and lamination, require controlled temperatures to maintain material integrity. PCB Industry Chillers provide a steady cooling source, indirectly helping keep each process within its required temperature range. This control enhances consistency and reduces the likelihood of defects in the finished product. |

| Reduced Thermal Stress on Components | High-power electronic components and densely packed PCBs are especially sensitive to temperature fluctuations. PCB Industry Chillers stabilize the coolant temperature used in thermal management systems, ensuring that heat is efficiently dissipated, and preventing thermal stress that could affect performance or longevity of the components. |

| Improved Yield and Quality | Temperature deviations can lead to poor adhesion in soldering or inconsistency in photoresist layers. By keeping process temperatures stable, PCB Industry Chillers indirectly help reduce material stress and production errors, improving the yield and quality of the finished PCBs. |

Key Features for Temperature Stability

| Feature | Description |

|---|---|

| Precision Cooling Technology | PCB Industry Chillers are engineered with high-precision temperature control capabilities, allowing them to maintain stable temperatures even in demanding environments. |

| Advanced Control Systems | Equipped with smart controls, these chillers adapt to changing cooling demands and maintain consistent temperatures without constant manual adjustments. |

| Efficient Heat Exchange | With optimized heat exchange systems, PCB Industry Chillers provide efficient cooling, ensuring that all parts of the production line remain within ideal temperature ranges. |

Installation and Maintenance

Installation Requirements

Proper installation of PCB Industry Chillers is essential to achieve the cooling stability required in PCB manufacturing. Here are some key considerations:

Optimal Placement and Ventilation

Ensure the chiller is installed in a well-ventilated area to maintain airflow and prevent overheating. PCB Industry Chillers often operate continuously in manufacturing settings, so positioning the unit where heat can dissipate efficiently is critical.

Stable and Secure Setup

Install the chiller on a stable, level surface to minimize vibrations, which can affect performance and durability. Placing the chiller close to the cooling loop but away from direct sunlight or other heat sources will support consistent cooling.

Electrical Compliance

Verify that the facility’s electrical setup meets the chiller’s power and voltage requirements to avoid power fluctuations that could impact its efficiency. Consulting with an electrician during installation helps ensure reliable operation.

Maintenance Tips for Optimal Performance

Regular maintenance is key to keeping PCB Industry Chillers performing efficiently and supporting stable temperatures throughout the manufacturing process:

•Routine Cleaning: Clean the air filters, condensers, and evaporator coils r

| Maintenance Task | Description |

|---|---|

| Routine Cleaning | Clean the air filters, condensers, and evaporator coils regularly to prevent dust buildup, which can reduce cooling efficiency. Regular cleaning helps maintain stable operation, essential for temperature-sensitive processes in PCB production. |

| System Inspections | Frequently check coolant levels, refrigerant pressure, and flow rates. Ensuring these elements are at optimal levels minimizes the risk of unexpected temperature fluctuations that could impact PCB quality. |

| Seasonal Adjustments | For facilities that experience seasonal temperature changes, adjusting maintenance frequency can help ensure stable performance. In hotter months, more frequent checks may be needed to avoid overheating. |

| Professional Maintenance | Schedule regular professional maintenance to check critical components like compressors, valves, and control systems. Professional inspections can identify and address issues early, reducing the risk of costly repairs and downtime. |

Energy Consumption and Cost-Effectiveness

Energy Efficiency of Screw Type Air-Cooled Chillers

PCB Industry Chillers are designed to handle the high demands of PCB production while maintaining energy efficiency, which is crucial for reducing operational costs over time. Here’s how these chillers provide efficient, cost-effective cooling:

Optimized Cooling Systems

PCB Industry Chillers use advanced cooling technology to deliver stable temperatures without excessive energy use. By providing only the necessary cooling to maintain optimal conditions, these chillers help PCB manufacturers minimize energy waste.

Variable Speed Compressors

Many PCB Industry Chillers come equipped with variable-speed compressors that adjust power output based on real-time cooling needs. This feature helps conserve energy during lower demand periods, such as production pauses or off-peak hours, directly reducing electricity costs.

High Efficiency in High-Precision Processes

Because PCB production often requires continuous, precise cooling, these chillers are engineered to operate efficiently in demanding conditions. Their design minimizes the need for additional cooling cycles, saving on energy and reducing wear on components.

Balancing Initial Investment with Operational Savings

Investing in a PCB Industry Chiller offers long-term cost benefits that offset the initial purchase and setup costs. Here’s what to consider:

Reduced Maintenance and Downtime

By using reliable components and energy-efficient designs, PCB Industry Chillers require less frequent maintenance and experience fewer breakdowns. This reliability reduces costly downtime, ensuring uninterrupted production.

Lower Operational Costs

The energy-efficient operation of these chillers directly contributes to lower monthly utility bills. This is particularly beneficial for facilities that operate 24/7, where continuous cooling is essential to maintain consistent production quality.

Extended Equipment Lifespan

PCB Industry Chillers are built to withstand high demands over extended periods. Their efficient performance reduces the strain on the equipment, contributing to a longer operational lifespan and lower replacement costs.

Brand and After-Sales Support

Trust in Kaydeli’s Expertise

Choosing a reliable brand like Kaydeli for PCB Industry Chillers ensures consistent, high-quality performance tailored to the needs of PCB manufacturing. Here’s why Kaydeli is a trusted choice:

Proven Reliability

Kaydeli chillers are designed and tested to meet stringent industry standards, providing stable, precise cooling essential for maintaining PCB quality.

Innovative Technology

Kaydeli integrates advanced cooling technology and energy-saving features into its PCB Industry Chillers, supporting reliable, efficient temperature control that keeps pace with modern production demands.

Sustainable Design

Kaydeli’s commitment to energy efficiency and eco-friendly manufacturing practices aligns with the sustainability goals of today’s PCB industry, offering chillers that minimize environmental impact.

Comprehensive After-Sales Support

Kaydeli provides extensive after-sales support to ensure long-term chiller performance and customer satisfaction. Here’s what customers can expect:

Installation Assistance

Kaydeli’s professional support team offers guidance to help customers install their chillers correctly, maximizing performance from the start.

Scheduled Maintenance Plans

Kaydeli offers maintenance programs designed to keep chillers in top condition, reducing the risk of unexpected downtime and helping customers maintain continuous production.

24/7 Technical Support

With dedicated technical assistance, customers can receive help anytime they need it, ensuring minimal disruption to their operations.

Warranty and Repair Services

Kaydeli’s robust warranty options provide customers with coverage for repairs or replacements, giving them peace of mind and ensuring their investment is protected.

Customer Feedback and Case Studies

Hearing from other users can be invaluable when selecting the right chiller. Here are some highlights of customer feedback from various industries that use Kaydeli chillers:

Electronics Manufacturing Facility

Kaydeli’s PCB Industry Chiller has been a valuable addition to our production line. It keeps our equipment at a stable temperature, indirectly preventing heat-related defects in our PCBs. We’ve seen improved consistency and reduced rework, which has boosted our production quality.

Global Circuits Inc.

Our high-output facility needs precise temperature control to maintain quality standards. Kaydeli’s chiller provides the reliable cooling we need to keep our equipment running smoothly, allowing us to meet large production demands without compromising on quality.

Skyline Hospitality Group

Our hotel guests rely on a comfortable, quiet environment, and Kaydeli’s Screw Type Chillers meet these needs perfectly. The energy efficiency has brought down our operating costs, while the low noise level enhances guest comfort. We’re pleased with the consistency and quality these chillers provide.