- Kaydeli

- Scroll or Piston Water Chiller

Scroll or Piston Water Chiller

Catalogue:Réfrigérants refroidis par eau

Cooling Capacity: 9-190 KW

Déterminez la capacité de refroidissement adaptée à votre installation en estimant les besoins en kilowatts par heure. 🤓

|

Capacité de refroidissement : --

|

|

Principe de fonctionnement de base des refroidisseurs

Les groupes frigorifiques fonctionnent sur la base d'un cycle du réfrigérant pour assurer un refroidissement efficace en extrayant la chaleur des zones désignées. Ce cycle comprend quatre étapes principales :

Compression

Condensation

Expansion

Évaporation

Ce processus permet aux refroidisseurs de fournir un refroidissement constant dans diverses applications industrielles et commerciales en éliminant continuellement la chaleur de l'environnement.

What Are Scroll and Piston Type Chillers?

Scroll and piston-type chillers are two specific air-cooled chillers with distinct compressor designs, each offering unique benefits for different cooling requirements.

Scroll compressors use a spiral scroll mechanism to achieve smooth and quiet refrigerant compression, making them ideal for environments where low noise is essential. Here’s how they work:

•The compressor consists of a fixed scroll and a moving scroll that rotates within it, gradually compressing the refrigerant to high pressure.

•This design eliminates intense mechanical contact, reducing noise and vibration.

-Ideal Applications: Scroll compressors are well-suited for office buildings, hotels, and public spaces where a quiet, stable cooling system is preferred.

Piston compressors, also known as reciprocating compressors, rely on a piston-driven mechanism that creates high-pressure cooling, making them ideal for demanding cooling applications. Here’s their operation:

•The piston compressor uses pistons within cylinders, similar to an engine, to compress refrigerant with strong force.

•This design allows for high compression ratios, delivering more powerful cooling for intensive applications.

-Ideal Applications: Piston compressors are commonly used in industrial settings, laboratories, and manufacturing plants, where high cooling power is essential.

Key Differences Between Scroll and Piston Compressors

-Noise Level: Scroll compressors offer quieter operation and are suitable for noise-sensitive environments.

-Cooling Power: Piston compressors provide higher cooling capacity and pressure, making them ideal for industrial applications requiring intensive cooling.

Differences Between Scroll and Piston Compressors

Les refroidisseurs d'eau à spirale et à piston se distinguent par la technologie de leur compresseur, chacun offrant des caractéristiques et des avantages uniques adaptés à différentes applications. Comparés à d'autres types de refroidisseurs d'eau, tels que les modèles à vis et centrifuges, ces refroidisseurs se distinguent par des aspects spécifiques.

| Fonctionnalité | Scroll Compressors | Piston Compressors | Screw Compressors | Centrifugal Compressors |

|---|---|---|---|---|

| Working Mechanism | Interlocking spiral scrolls compress refrigerant smoothly. | Piston motion in cylinders compresses refrigerant. | Rotary screws compress refrigerant continuously. | Rotating impeller compresses refrigerant using centrifugal force. |

| Bruit et vibrations | Low; suitable for quiet environments. | Moderate; handles industrial conditions. | Moderate; stable for continuous use. | Low; ideal for large-scale, quiet operations. |

| Capacité de refroidissement | Modéré ; idéal pour les applications de petite et moyenne taille. | High; handles demanding industrial loads. | Very high; suitable for large-scale facilities. | Extremely high; used in massive facilities like power plants. |

| Efficacité énergétique | High for moderate cooling demands. | Moderate; durable for heavy-duty use. | High; optimized for continuous operations. | Very high; excellent for large-scale efficiency. |

| Applications | Offices, labs, small-scale industries. | Heavy-duty industries, chemical plants, plastic molding. | Large factories, manufacturing facilities. | Power plants, large commercial buildings. |

Ressources

Exigences en matière de refroidissement

Besoins en capacité de refroidissement

Il est essentiel de déterminer la capacité de refroidissement adéquate pour garantir des performances et une efficacité énergétique optimales. Les besoins en capacité de refroidissement varient en fonction de facteurs tels que la charge thermique, la température souhaitée et la taille de l'application. Pour vous aider à faire le bon choix, nous avons inclus un tableau de calcul simple sur cette page. Cet outil permet d'estimer la charge de refroidissement (en kW ou TR) nécessaire pour votre installation spécifique, vous guidant ainsi vers le modèle de refroidisseur idéal pour répondre efficacement à vos demandes de refroidissement.

| Étape | Description |

|---|---|

| 1. Déterminer la charge thermique | Évaluez la chaleur totale produite par votre équipement ou votre processus. Cette information figure souvent dans les spécifications de l'équipement. |

| 2. Appliquer les formules de refroidissement | Utilisez des formules ou des calculateurs industriels pour convertir la charge thermique en capacité de refroidissement, en tenant compte de la chute de température souhaitée et de la taille de la zone. |

| 3. Choisir en fonction de la capacité | Une fois que le nombre de kW ou de TR nécessaires est déterminé, choisissez un refroidisseur d'une capacité suffisante pour gérer efficacement votre charge de refroidissement. |

Les refroidisseurs de type Scroll et Piston sont polyvalents et peuvent répondre à un large éventail de demandes de refroidissement. Pour des besoins de refroidissement modérés à élevés dans des applications à température standard, ces refroidisseurs offrent des performances fiables et efficaces sur le plan énergétique.

Scénarios d'application

Scroll and Piston Water Chillers are versatile cooling solutions designed to meet the specific needs of various industries. Their ability to provide precise and efficient cooling makes them indispensable in several applications.

Fabrication industrielle

-Refroidisseurs à spirale: Suitable for small to mid-scale operations, such as light manufacturing and tool cooling.

-Refroidisseurs à piston: Ideal for heavy-duty equipment like hydraulic presses, injection molding machines, and extrusion lines.

-Bénéfice: Maintains consistent equipment temperatures, ensuring efficient operation and reducing downtime.

Plastic and Rubber Processing

-Refroidisseurs à spirale: Used for mold temperature control in smaller-scale production.

-Refroidisseurs à piston: Handles larger-scale operations, providing cooling for molds and machinery in high-output facilities.

-Bénéfice: Ensures uniform product quality by stabilizing mold and machinery temperatures.

Industrie alimentaire et des boissons

-Refroidisseurs à spirale: Perfect for refrigeration and small-scale storage systems.

-Refroidisseurs à piston: Suitable for larger-scale operations, such as cooling water for brewing, dairy, or food processing.

-Bénéfice: Maintains product freshness by providing precise temperature control for refrigeration systems.

HVAC Systems

-Refroidisseurs à spirale: Common in small to mid-sized commercial buildings, providing efficient cooling for offices, retail spaces, and schools.

-Refroidisseurs à piston: Used in large commercial or industrial HVAC systems where higher cooling capacities are required.

-Bénéfice: Creates comfortable indoor environments while optimizing energy consumption.

Contrôle et stabilité de la température

Maintaining Optimal Water Temperatures

Scroll and Piston Water Chillers are designed to provide precise and stable temperature control, ensuring the efficiency and reliability of industrial and commercial processes. Their ability to maintain consistent water temperatures is critical for applications where even slight fluctuations can compromise performance.

| Fonctionnalité | Description |

|---|---|

| Advanced Temperature Control Systems | Both Scroll and Piston Water Chillers are equipped with smart control systems that monitor and regulate water temperatures in real time. This ensures consistent cooling performance even under varying load conditions. |

| High Precision for Sensitive Applications |

Scroll Chillers: Offer precise temperature control with minimal fluctuations, ideal for applications like laboratories and data centers where stability is crucial. Piston Chillers: Deliver robust cooling for processes with higher thermal loads, ensuring reliable performance even in demanding industrial environments. |

| Large plage de fonctionnement | Capable of maintaining water temperatures from as low as 5°C to as high as 30°C, making these chillers versatile for a range of cooling needs across different industries. |

| Rapid Response to Temperature Changes | Both types of chillers respond quickly to changes in cooling demand, minimizing downtime and preventing thermal stress on equipment. |

Avantages de la stabilité de la température de l'eau

| Bénéfice | Description |

|---|---|

| Improved Equipment Performance | Consistent cooling prevents overheating, ensuring that machinery operates at peak efficiency and reducing wear and tear on components. |

| Enhanced Product Quality | In processes like plastic molding and chemical production, stable temperatures improve product consistency and reduce defects caused by temperature variations. |

| Efficacité énergétique | By maintaining precise temperatures, Scroll and Piston Chillers minimize energy waste, lowering operational costs while maintaining performance. |

| Prolonged Equipment Lifespan | Preventing temperature fluctuations reduces mechanical stress, extending the lifespan of both the chiller and connected equipment. |

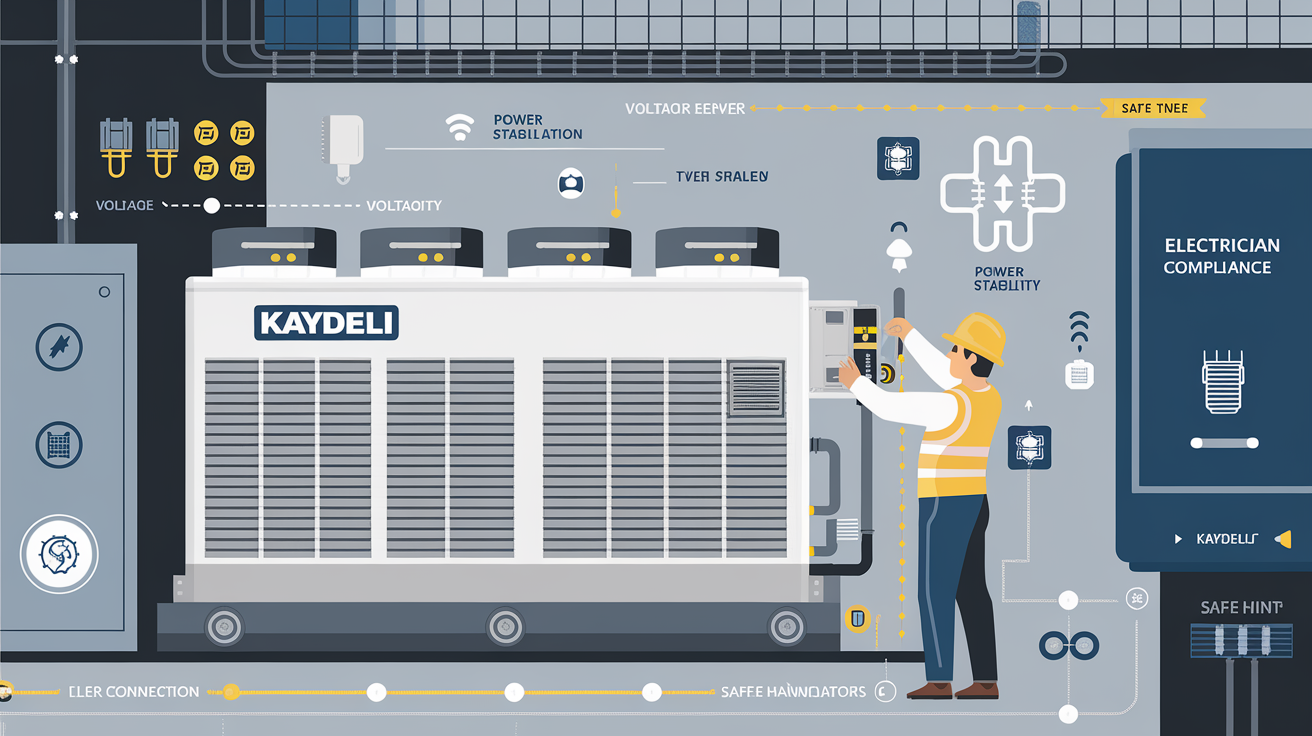

Installation et entretien

Installation Requirements for Optimal Performance

Proper installation is essential to maximize the efficiency and reliability of Scroll or Piston Water Chillers. Here are key considerations:

Exigences en matière d'espace

Place the chiller in a well-ventilated area to ensure proper heat dissipation and avoid overheating. Water-cooled chillers should also be installed near a stable water supply to optimize efficiency.

Surface and Positioning

Install the chiller on a level, vibration-free surface to prevent operational instability. A stable foundation protects internal components and ensures consistent cooling performance.

Configuration électrique

Verify that the electrical supply meets the chiller’s power requirements. A licensed electrician should handle wiring and connections to prevent surges or electrical disruptions.

Maintenance Tips for Longevity and Efficiency

Routine maintenance is critical to keep your Scroll or Piston Water Chiller operating at peak performance. Here’s a recommended maintenance plan:

| Tâche | Description |

|---|---|

| Nettoyage régulier | Clean water filters, heat exchangers, and evaporators to prevent buildup of dirt or scale, which can reduce cooling efficiency. For water-cooled systems, inspect and clean cooling towers or water supply lines regularly. |

| Contrôle des niveaux de réfrigérant | Check refrigerant levels periodically to ensure the system operates efficiently. Low refrigerant levels can lead to reduced cooling capacity and higher energy consumption. |

| Inspect and Replace Worn Components | Regularly inspect critical components like compressors, valves, and pumps for wear or damage. Replace any parts showing signs of deterioration to avoid breakdowns. |

| Water Quality Management | Ensure that the water used in the cooling system is clean and free from contaminants. Treat water to prevent scaling and corrosion in the heat exchangers. |

| Entretien professionnel | Schedule regular servicing by trained professionals to perform thorough system inspections, recalibrate controls, and ensure all components are functioning optimally. |

Efficacité énergétique et rentabilité

Conçu pour l'efficacité énergétique

Kaydeli’s Scroll and Piston Water Chillers are engineered with energy-saving features to provide optimal cooling while minimizing energy consumption. Here’s how they achieve outstanding efficiency:

Transfert de chaleur efficace

Les échangeurs de chaleur haute performance maximisent l'efficacité du refroidissement en assurant un transfert de chaleur optimal. La charge de travail des compresseurs est ainsi réduite, ce qui diminue la consommation d'énergie.

Technologie avancée des compresseurs

Les compresseurs Scroll offrent un refroidissement économe en énergie pour les demandes modérées, tandis que les compresseurs à piston offrent un refroidissement puissant et efficace pour les applications lourdes.

Contrôle intelligent de la température

Équipés de systèmes de contrôle avancés, ces refroidisseurs adaptent la puissance frigorifique en fonction de la demande en temps réel. Cela permet de réduire la consommation d'énergie inutile pendant les périodes de faible demande et d'améliorer l'efficacité globale.

Optimisé pour les systèmes refroidis par eau

Les modèles refroidis à l'eau consomment moins d'énergie que les modèles refroidis à l'air, en particulier dans les environnements où les besoins de refroidissement sont élevés. Cette conception les rend particulièrement rentables pour les applications industrielles et commerciales.

Avantages financiers à long terme

Investing in Scroll or Piston Water Chillers provides significant cost savings over their lifespan. Here’s how:

Réduction des frais de maintenance

Durable components and optimized designs minimize wear and tear, lowering the frequency and cost of repairs.

Réduction des coûts opérationnels

Energy-efficient compressors and heat exchangers reduce electricity bills, especially in facilities that require continuous operation.

Prolongation de la durée de vie de l'équipement

Stable temperature control reduces mechanical stress on the chiller and connected equipment, prolonging their operational life and delaying costly replacements.

Amélioration de la productivité

Reliable cooling reduces downtime, allowing facilities to maintain consistent production schedules and meet operational targets.

Soutien à la marque et au service après-vente

Trust in Kaydeli’s Expertise

Kaydeli is a global leader in industrial cooling solutions, known for its innovative designs, durable products, and commitment to customer satisfaction. Here’s why Kaydeli’s Scroll or Piston Water Chillers are the preferred choice for industrial and commercial applications:

Unmatched Quality Standards

Kaydeli chillers are built with premium materials and cutting-edge technology, ensuring reliable and long-lasting performance under demanding conditions.

Expertise sectorielle

With years of experience in diverse industries, Kaydeli provides tailored cooling solutions to meet unique operational requirements.

Engagement en faveur du développement durable

Kaydeli integrates energy-efficient components and environmentally friendly refrigerants, helping businesses achieve sustainability goals.

Support après-vente complet

Kaydeli ensures peace of mind for its customers by offering a robust after-sales support system, designed to maximize chiller performance and longevity:

Assistance professionnelle à l'installation

Expert guidance during installation ensures the chiller operates efficiently from day one, reducing setup errors and optimizing performance.

Plans de maintenance personnalisés

Tailored maintenance schedules help keep the chiller in peak condition, minimizing downtime and ensuring consistent performance.

Assistance technique 24/7

Kaydeli’s dedicated support team is available around the clock to resolve any issues quickly, ensuring minimal operational disruptions.

Services de garantie et de réparation

Comprehensive warranty options protect your investment, with prompt repairs or replacements to keep operations running smoothly.

Commentaires des clients et études de cas

L'avis d'autres utilisateurs peut s'avérer précieux pour choisir le bon refroidisseur. Voici quelques exemples de commentaires de clients de diverses industries qui utilisent les refroidisseurs Kaydeli :

PolyTech Plastics

Kaydeli’s Piston Water Chiller has significantly improved the cooling consistency in our injection molding process. We’ve seen a 20% reduction in defects and smoother operation overall.

FreshBev Co.

We use Kaydeli’s Piston Chiller for cooling in our bottling line, and it’s been incredibly reliable, even during peak production times. Energy savings have also exceeded expectations.

Innovations pharmaceutiques

Le refroidisseur d'eau Scroll a changé la donne pour les processus sensibles à la température de notre laboratoire. Il fonctionne silencieusement et efficacement, ce qui nous permet de maintenir des conditions précises pour le contrôle de la qualité.