- Kaydeli

- Pompe à chaleur centrifuge industrielle de grande capacité à 120°C

Pompe à chaleur centrifuge industrielle de grande capacité à 120°C

Catalogue:Heat Pumps Chillers

Déterminez la capacité de refroidissement adaptée à votre installation en estimant les besoins en kilowatts par heure. 🤓

|

Heating Capacity: --

|

|

Principe de fonctionnement simplifié des pompes à chaleur

Les pompes à chaleur fonctionnent en absorbant la chaleur de l'air, en la comprimant pour augmenter l'énergie, en libérant la chaleur pour l'utiliser et en recyclant le réfrigérant pour un chauffage ou un refroidissement continu.

Absorption de la chaleur

Compression

Dégagement de chaleur

Expansion

What is a 120°C Large-Capacity Industrial Centrifugal Heat Pump?

Le Pompe à chaleur à vis haute température 120°C is an advanced heating solution designed to deliver reliable and energy-efficient heating for industrial processes that require high-temperature outputs. Its innovative design allows it to achieve temperatures up to 120°C, making it a perfect choice for demanding applications in industries such as chemical processing, food manufacturing, and district heating.

| Fonctionnalité | Description |

|---|---|

| Exceptional Heating Capacity |

– Provides a maximum heating output of up to 10 MW, making it ideal for large-scale industrial applications. – Delivers consistent high temperatures up to 130°C, ensuring reliable performance for demanding processes. |

| Advanced Centrifugal Compressor Technology |

– Equipped with a high-efficiency centrifugal compressor that ensures low energy consumption while delivering high output. – Reduces wear and tear compared to other compressor types, ensuring long-term reliability. |

| High COP Efficiency |

– Achieves a Coefficient of Performance (COP) of up to 6.6, significantly reducing operational costs compared to traditional heating systems. – Optimized for both high and low-temperature conditions, maintaining performance even in challenging environments. |

| Eco-Friendly Operation |

– Utilizes environmentally friendly refrigerants with low-GWP (Global Warming Potential) to minimize environmental impact. – Incorporates advanced heat recovery technology to maximize energy efficiency and sustainability. |

| Simplified Installation and Maintenance |

– Modular design allows for easy integration into existing systems. – Durable components and advanced control systems minimize maintenance requirements. |

| Stage | Process | Key Details |

|---|---|---|

| Heat Absorption (Evaporation) | Heat is absorbed from a renewable energy source, such as groundwater, industrial waste heat, or a cooling water loop. | The evaporator transfers the absorbed heat to the refrigerant, which evaporates into a low-pressure gas. |

| Compression | The low-pressure gas is compressed by a centrifugal compressor, significantly increasing its temperature and pressure. | This step is essential for achieving high-temperature outputs while maintaining energy efficiency. |

| Heat Release (Condensation) | The high-pressure, high-temperature refrigerant releases heat in the condenser, transferring it to water or another working fluid. | Heated water or fluid is delivered at temperatures up to 130°C for industrial applications. |

| Expansion | After releasing heat, the refrigerant’s pressure and temperature are reduced through an expansion valve. | Prepares the refrigerant to repeat the cycle efficiently in continuous operation. |

120°C Centrifugal Heat Pump vs Boilers & Other Heat Systems

Compare the 120°C Large-Capacity Industrial Centrifugal Heat Pump with traditional boilers, screw heat pumps, and air source systems. Discover its superior efficiency, eco-friendliness, and industrial versatility.

| Fonctionnalité | 120°C Centrifugal Heat Pump | Traditional Boilers | Screw Heat Pumps | Pompes à chaleur à air |

|---|---|---|---|---|

| Source d'énergie | Renewable sources like water or waste heat. | Fossil fuels (coal, oil, gas). | Renewable or industrial heat sources. | Ambient air; efficiency drops in cold climates. |

| Heating Capacity | Up to 10 MW, suitable for large-scale applications. | High, but requires significant energy input. | Medium capacity, typically up to 5 MW. | Limited to small and medium-scale applications. |

| Efficiency (COP) | Up to 6.6, offering superior energy savings. | Low, due to combustion heat loss. | Moderate, typically between 3.5 and 5.0. | Low in colder climates; highly dependent on ambient temperatures. |

| Environmental Impact | Low emissions with eco-friendly refrigerants. | High emissions due to fossil fuel combustion. | Lower emissions but refrigerants may impact the environment. | Low emissions but limited by efficiency in extreme climates. |

| Plage de température | Delivers consistent heat up to 130°C. | Can reach high temperatures but at a higher energy cost. | Typically supports temperatures up to 100°C. | Limited to 70°C–80°C. |

| Applications | Industrial processes, district heating, and food processing. | Legacy systems or high-temperature niche applications. | Medium-scale industrial applications. | Residential or light commercial use. |

Ressources

Heating Requirements

Heating Capacity Needs

Selecting the right heating capacity is essential for ensuring the optimal performance and efficiency of the Pompe à chaleur centrifuge industrielle de grande capacité à 120°C. Below are the key considerations when determining your heating requirements.

| Aspect | Détails |

|---|---|

| 📊 Process Heating Demand |

- Calculate the total heat load required for processes like sterilization, drying, or chemical reactions. - Match system capacity to the required output in kilowatts (kW) or megawatts (MW). |

| 🏭 Application Size |

- Large-scale applications (up to 10 MW) are ideal for extensive industrial needs. - Modular setups can suit smaller operations while allowing future scalability. |

| 🌊 Heat Source Characteristics |

- Ensure access to consistent sources like water, geothermal energy, or waste heat. - Optimal source temperatures range from 10°C to 25°C for efficient operation. |

| 🏷️ Industry Examples |

Food Processing: 500 kW–2 MW for sterilization and pasteurization. District Heating: 3 MW–10 MW for large-scale residential or commercial use. Chemical Manufacturing: 1 MW–5 MW for distillation or reactions. Textile Industry: 500 kW–3 MW for dyeing and drying fabrics. |

| 🔄 Scalability |

- Choose systems that can adapt to future demand increases without major upgrades. - Slightly oversize the capacity to handle fluctuations while maintaining efficiency. |

Where 120°C Large-Capacity Industrial Centrifugal Heat Pump Excel

Le Pompe à chaleur centrifuge industrielle de grande capacité à 120°C is designed for demanding industrial and commercial applications that require consistent, high-temperature heating. Here are the key scenarios where this system performs exceptionally well:

Textile and Garment Industry

-Applications:

Heating processes for dyeing, washing, and fabric finishing.

Maintaining humidity levels for fabric quality.

-Benefits:

Delivers consistent heat for uniform fabric processing.

Reduces energy consumption in large-scale operations.

Pharmaceutical and Chemical Manufacturing

-Applications:

Steam sterilization of medical tools and production equipment.

High-temperature processes like distillation and chemical reactions.

-Benefits:

Ensures compliance with strict hygiene and safety standards.

Reduces carbon emissions compared to fossil fuel-based systems.

Food and Beverage Processing

-Applications:

Steam generation for sterilizing food containers and processing equipment.

Cooking, pasteurization, and drying of food products.

-Benefits:

Precise temperature control ensures food safety and quality.

Energy-efficient operation reduces operational costs compared to traditional boilers.

District Heating Systems

-Applications:

Centralized heating for residential, commercial, and industrial buildings.

Supplying hot water and space heating across urban areas.

-Benefits:

Provides cost-effective and sustainable heating for large-scale communities.

Supports renewable energy integration for greener operations.

Temperature Requirements for 120°C Large-Capacity Industrial Centrifugal Heat Pump

Le Pompe à chaleur centrifuge industrielle de grande capacité à 120°C is designed to operate efficiently across a wide range of input and output temperatures, ensuring optimal performance for demanding industrial applications. Understanding temperature requirements is crucial for selecting and operating the system effectively.

| Aspect | Détails |

|---|---|

| 🌡️ Optimal Operating Temperature |

- Output temperatures reach up to 120°C, ideal for high-temperature industrial processes. - Input heat source temperature operates best between 10°C and 25°C for efficient heat absorption. |

| ❄️ Low-Temperature Input |

- Performs efficiently even with source temperatures as low as 5°C. - Additional pre-heating mechanisms may be required for extremely low input temperatures. |

| 🔥 High-Temperature Applications |

- Capable of maintaining consistent output temperatures from 100°C to 120°C. - Ideal for sterilization, drying, and chemical processes requiring high-grade heat. |

| 🏭 Industry-Specific Needs |

Food and Beverage: 80°C–120°C for sterilization and pasteurization. Pharmaceutical: 100°C–120°C for steam sterilization. Textile Industry: 70°C–100°C for dyeing and finishing. Chemical Manufacturing: 90°C–120°C for distillation and reactions. |

| 🌍 Environmental Factors |

- Performance is unaffected by ambient temperatures due to stable water-based heat sources. - Proper insulation is essential to prevent heat loss during high-temperature applications. |

| ✅ Benefits of Proper Temperature Matching |

- Ensures optimal efficiency, minimizing energy waste. - Prolongs system lifespan by avoiding unnecessary strain. - Reduces operational costs while maintaining reliable performance. |

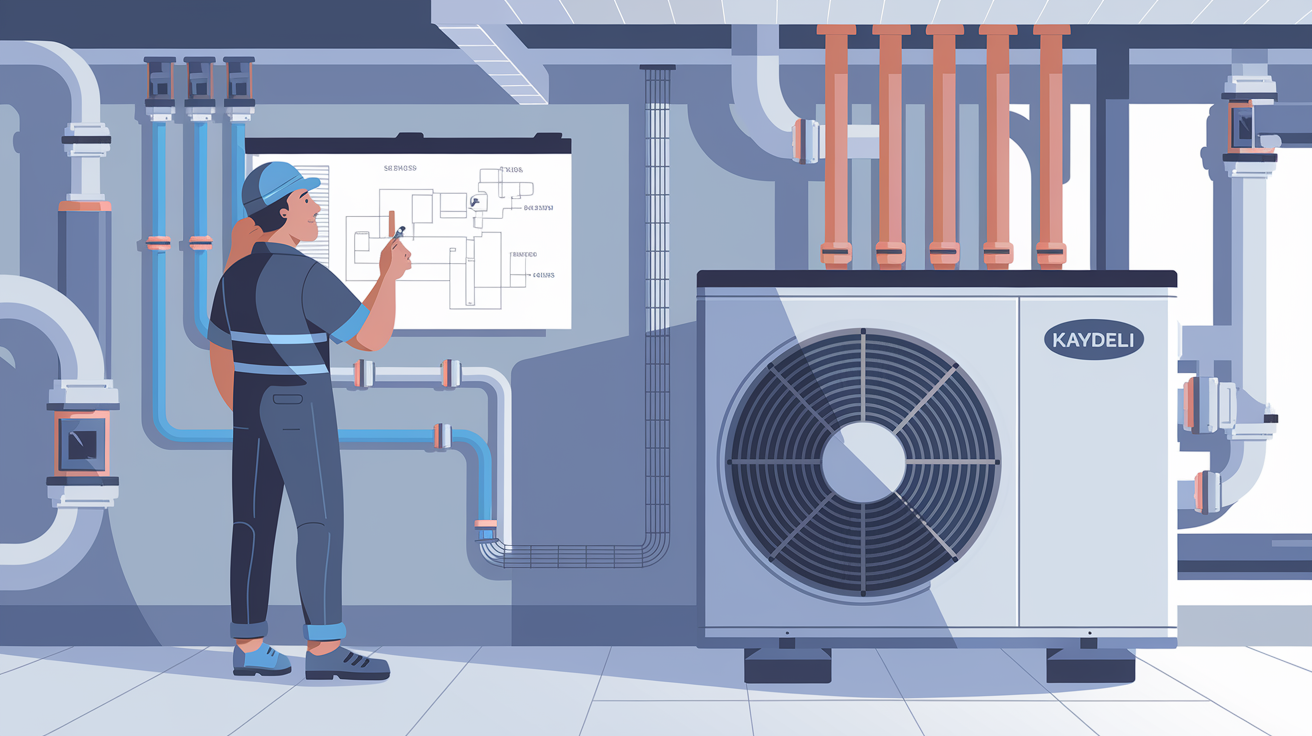

Installation et entretien

Proper installation and consistent maintenance are essential for ensuring the efficient and reliable operation of 120°C High-Temperature Screw Heat Pumps. This section provides a comprehensive guide to achieving optimal performance and long-term durability.

Lignes directrices pour l'installation

📍 Site Preparation

Ensure sufficient space for the heat pump and its components, allowing proper airflow and easy access for maintenance. Position the system close to the heat source (e.g., water or industrial waste heat) to minimize piping costs and heat loss.

🔧 System Integration

Verify compatibility with existing industrial processes or heating systems. Engage professional technicians to securely connect the system to power, water, and other utilities.

🌊 Water Quality Considerations

Assess water quality for potential impurities requiring filtration or treatment before use. Ensure a stable and consistent water supply to maintain optimal heat pump performance.

🛠️ Initial Testing

Test all components, including compressors, valves, and controls, to ensure proper operation. Confirm the system delivers consistent heat output at the required temperature range (up to 120°C).

Maintenance Best Practices

L'entretien régulier est essentiel pour préserver l'efficacité et la longévité des refroidisseurs à vis. Voici les étapes essentielles de l'entretien :

| Tâche de maintenance | Détails |

|---|---|

| 🧼 Regular Cleaning |

- Clean heat exchangers and water filters to prevent scaling, corrosion, or debris buildup that can reduce efficiency. - Flush the water circuit periodically to maintain smooth operation. |

| ⚙️ Component Inspections |

- Regularly inspect critical parts like compressors, pumps, and valves for signs of wear or damage. - Monitor refrigerant levels and top up if necessary to ensure efficient operation. |

| 🔍 Performance Monitoring |

- Use smart monitoring systems (if available) to track temperature output, energy consumption, and system performance. - Set up alerts for irregularities to address issues proactively. |

| 📅 Scheduled Servicing |

- Schedule annual professional servicing to perform in-depth inspections, recalibrate controls, and replace worn components. - Check and optimize system efficiency to prevent unexpected downtime. |

| 🌡️ Water Quality Management |

- Regularly test water for pH levels and impurities to prevent scaling and ensure longevity of the heat exchangers. - Install a water treatment system if operating in areas with poor water quality. |

Benefits of Proper Installation and Maintenance

-Efficacité énergétique: Maintains consistent performance, reducing operational energy costs.

-Longevity: Prevents component failures and extends the system’s lifespan.

-Reliability: Ensures continuous high-temperature output, even during peak demand periods.

-Cost Savings: Avoids costly repairs and minimizes system downtime.

Efficacité énergétique et rentabilité

Le Pompe à chaleur à vis haute température 120°C is designed to deliver exceptional energy efficiency while significantly reducing operational costs. This makes it an ideal solution for industries looking to balance high-performance heating with long-term sustainability.

Superior Energy Efficiency

Achieves exceptional performance with high COP values, efficient heat recovery, and minimal energy loss, ensuring optimal heating with reduced energy consumption.

⚡ High Coefficient of Performance (COP)

Achieves COP values above 4.0, meaning the system generates over four units of heat for every unit of electricity consumed.

🔄 Efficient Heat Recovery

Captures and reuses waste heat from industrial processes, reducing overall energy consumption.

📉 Minimal Energy Loss

Advanced screw compressor technology ensures precise energy usage, with minimal waste during heat transfer.

Operational Cost Savings

Lowers utility bills and maintenance costs by optimizing energy use, leveraging durable components, and integrating smart control systems for real-time efficiency.

💡 Reduced Energy Costs

Energy-efficient operation directly lowers utility bills for heating and steam generation.

🛠️ Lower Maintenance Costs

Durable components and simplified system design reduce the frequency and cost of maintenance.

🖥️ Smart Control Systems

Optimizes energy usage by adjusting output to match real-time heating demand, further reducing operating expenses.

Long-Term Sustainability

Supports environmental goals with low-GWP refrigerants, renewable energy integration, and compliance with stringent sustainability standards, reducing carbon emissions.

🌍 Environmentally Friendly Design

Utilizes low-GWP refrigerants, significantly reducing carbon emissions and supporting sustainability goals.

🌱 Renewable Energy Integration

Compatible with renewable heat sources such as industrial waste heat or geothermal energy, further decreasing environmental impact.

📜 Compliance with Regulations

Helps industries meet strict environmental and energy efficiency standards, avoiding penalties or fines.

Cost-Benefit Analysis

Highlights the economic advantages of choosing energy-efficient systems over traditional boilers, including reduced energy costs, minimal maintenance, and eco-friendly operations.

| Cost Factor | Traditional Boilers | 120°C Centrifugal Heat Pump |

|---|---|---|

| Efficacité énergétique | Low due to heat loss | High with COP > 6.5 |

| Fuel Dependency | Fossil fuel dependent | Renewable heat sources |

| Operational Costs | High utility costs | Reduced energy expenses |

| Maintenance Costs | Frequent repairs | Predictive maintenance system |

| Environmental Impact | High carbon emissions | Low emissions, eco-friendly |

Why Energy Efficiency Matters

-Cost Reduction: Directly lowers energy bills and maintenance expenses.

-Environmental Impact: Supports sustainability goals with reduced carbon emissions.

-Operational Reliability: Ensures consistent performance across varied industrial processes.

-Long-Term Profitability: Lowers Total Cost of Ownership (TCO) over the system’s lifespan.

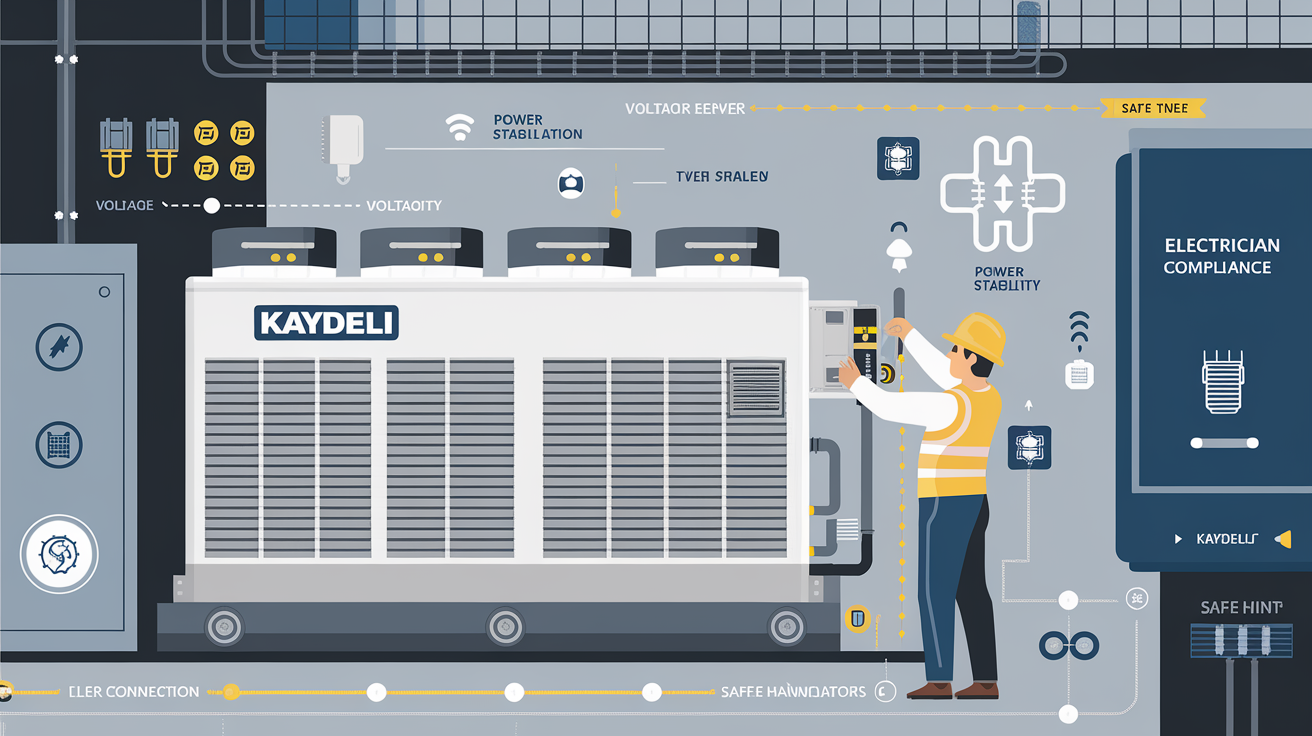

Soutien à la marque et au service après-vente

Investing in a Pompe à chaleur à vis haute température 120°C from Kaydeli means not just getting a high-performance product but also benefiting from industry-leading after-sales services. Kaydeli ensures that your system operates at peak efficiency and delivers long-term value.

Pourquoi choisir Kaydeli ?

Kaydeli est un leader mondial dans le domaine des solutions de chauffage et de refroidissement à haut rendement énergétique, réputé pour ses technologies innovantes et son soutien exceptionnel à la clientèle. Voici pourquoi Kaydeli se distingue :

Des normes de qualité exceptionnelles

Les refroidisseurs de Kaydeli sont construits avec des matériaux de qualité industrielle et une technologie avancée, ce qui garantit une durabilité et des performances constantes dans des conditions extrêmes.

Expertise sectorielle

Des années d'expérience dans diverses industries permettent à Kaydeli de fournir des solutions sur mesure qui répondent aux exigences uniques de chaque application.

Engagement en faveur du développement durable

Kaydeli donne la priorité aux conceptions respectueuses de l'environnement en intégrant des composants à haut rendement énergétique et des réfrigérants respectueux de l'environnement.

Fiabilité éprouvée

Les refroidisseurs Kaydeli, qui ont la confiance des plus grandes entreprises dans le monde entier, assurent un refroidissement précis et efficace des processus critiques.

Support après-vente complet

Kaydeli garantit la tranquillité d'esprit grâce à un solide programme après-vente conçu pour maximiser les performances et la durée de vie des produits.

Assistance professionnelle à l'installation

Des conseils d'experts lors de l'installation garantissent un fonctionnement efficace de votre refroidisseur dès le départ.

Plans de maintenance personnalisés

Des programmes d'entretien personnalisés permettent de maximiser les performances des refroidisseurs et de minimiser les temps d'arrêt.

Assistance technique 24/7

L'équipe d'assistance dédiée de Kaydeli est toujours disponible pour résoudre les problèmes rapidement, garantissant ainsi des opérations ininterrompues.

Services de garantie et de réparation

Des options de garantie complètes protègent votre investissement, avec des services de réparation rapides et efficaces.

La priorité de Kaydeli est d'offrir une valeur exceptionnelle à chaque client. En associant des produits innovants à un service après-vente exceptionnel, Kaydeli s'assure que les utilisateurs bénéficient d'une fiabilité, d'une efficacité énergétique et d'une assistance inégalées tout au long du cycle de vie du produit.

Commentaires des clients et études de cas

L'avis d'autres utilisateurs peut s'avérer précieux pour choisir le bon refroidisseur. Voici quelques exemples de commentaires de clients de diverses industries qui utilisent les refroidisseurs Kaydeli :

FreshTaste Food Processing Ltd.

Kaydeli’s heat pump not only improved our efficiency but also helped us meet environmental standards. It’s been an excellent investment!

PharmaCare Solutions

Kaydeli’s system ensures we meet the highest quality standards while staying energy-efficient. Highly recommended!

GlobalTextiles Group

The Kaydeli heat pump is a game-changer for our production line. We’ve seen noticeable cost savings and consistent results.