Temperature control problems plague countless manufacturing operations, causing production delays, quality issues, and wasted energy. Without precise cooling, critical processes fail and costs spiral out of control.

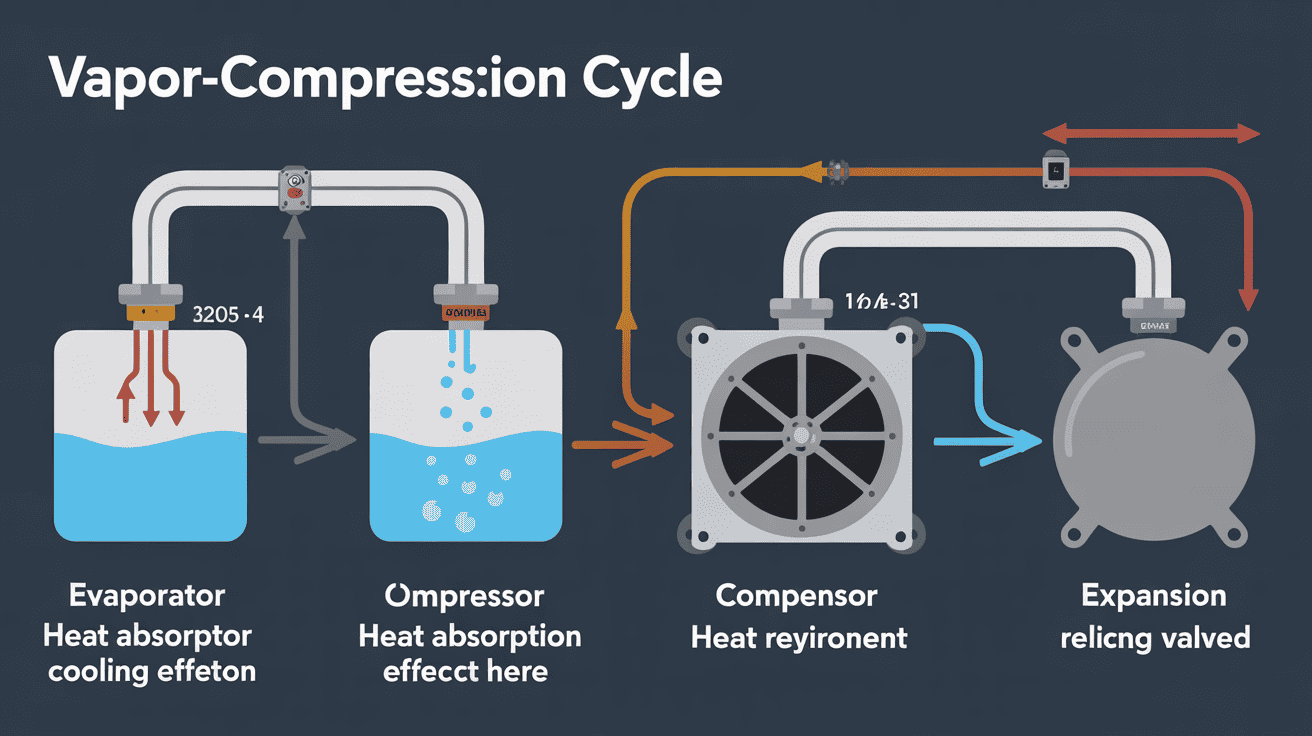

Industrial chillers work through a refrigeration cycle that removes Heat from process fluids or equipment. The system circulates refrigerant through four key components: evaporator (absorbs Heat), compressor (pressurizes refrigerant), condenser (releases heat), and expansion valve (reduces pressure). This closed-loop system continuously transfers Heat from your process to the external Environment.

After 15 years in refrigeration engineering before founding Kaydeli, I’ve seen firsthand how understanding chiller operation principles helps facility managers make better decisions. The evidence is clear—properly maintained chillers with optimal settings can reduce la consommation d'énergie1 by 30% or more. Let me walk you through how these essential cooling systems work.

What Are the Key Components of an Industrial Chiller System?

Many facility managers struggle with troubleshooting their chiller systems, wasting time and resources on ineffective repairs. Without knowing how each part functions, maintenance becomes guesswork rather than precision.

A standard industrial chiller consists of four primary components: the evaporator (absorbs Heat from process water), the compressor (increases refrigerant pressure and temperature), the condenser (rejects Heat to the Environment), and the expansion valve (reduces pressure to restart the cycle). These components work together in a closed loop to transfer Heat efficiently.

The Evaporator: Where Cooling Begins

The evaporator is where actual cooling of your process fluid happens. Choosing the right evaporator type dramatically affects system efficiency in my early designs.

Evaporators come in two main types:

- Plate Evaporators – Compact and efficient, ideal for smaller systems

- Shell and Tube Evaporators – Better for larger capacities and when fluid quality is variable

Inside the evaporator, the refrigerant absorbs Heat from the process water, changing from a liquid to a gas. This phase change is crucial—it allows the refrigerant to absorb large amounts of Heat without changing temperature significantly. Most industrial chillers cool water from around 12°C down to 7°C (54°F to 45°F), though specialized systems can reach temperatures as low as -40°F for applications like food freezing.

The Compressor: Powering the Cooling Process

The compressor is truly the heart of any chiller system. In my experience, compressor selection often determines the entire system’s efficiency and reliability.

Compressors in industrial chillers come in several types, each with specific applications and lifespans:

| Type de compresseur | Best Application | Efficacité | Lifespan | Plage de capacité |

|---|---|---|---|---|

| Reciprocating | Small to medium systems | Medium | 10-15 years | 10-200 tons |

| Vis | Medium to large systems | High | 15-20 years | 70-500 tons |

| Centrifugal | Large systems | Very High | 20-25 years | 100+ tons |

| Scroll | Small systems | High | 8-15 years | 10-100 tons |

At Kaydeli, we typically recommend screw compressors for most industrial applications because they balance efficiency, reliability, and maintenance requirements. When we introduced variable speed drives (VSDs) to our compressors, customers reported up to 30% energy savings at part-load conditions.

The compressor extracts the refrigerant vapor from the evaporator, raising its pressure and temperature. This pressure differential drives the entire refrigeration cycle2 and prepares the refrigerant for heat rejection in the next stage.

The Condenser: Rejecting Heat to the Environment

The condenser takes the hot, high-pressure refrigerant gas from the compressor and rejects its Heat to the surrounding Environment. This causes the refrigerant to condense into a liquid while maintaining high pressure.

There are two main condenser types:

- Air-cooled condensers – Use ambient air for heat rejection, typically with copper tubes and aluminum fins for heat transfer

- Water-cooled condensers – Use water (often from cooling towers) as the cooling medium, reducing energy use by over 15% compared to air-cooled systems

My research has shown that condenser water temperature dramatically impacts efficiency—for every 1°F increase above design temperature, chiller efficiency decreases by 1-2%. I’ve helped many clients implement cooling tower optimization strategies to keep condenser water temperatures as low as possible.

The Expansion Valve: Creating the Pressure Differential

The expansion valve, or a thermal expansion valve (TEV), sits between the condenser and evaporator. It creates a pressure drop in the refrigerant, allowing it to expand and cool before entering the evaporator.

This seemingly simple component has an outsized impact on system performance. In my design experience, improper expansion valve sizing can lead to inefficient cooling and compressor damage. Modern electronic expansion valves can precisely adjust to changing conditions, improving efficiency by 5-10% compared to mechanical valves.

Additional Critical Components

Beyond the four main components, industrial chillers include:

- Internal Tanks – Maintain consistent cold water temperature

- Pump Stations – Circulate water through the system and to process equipment

- Control Panels – Monitor and adjust system performance with fault indicators and alarms

- Water Treatment Systems – Prevent scale and biological growth that can reduce efficiency by 10-35%

How Does the Refrigeration Cycle Create Cooling Effects?

Despite using chillers daily, many engineers I’ve worked with find the refrigeration cycle2 confusing. This knowledge gap leads to suboptimal operation and missed opportunities for energy savings.

Industrial chillers create cooling through a four-stage vapor compression refrigeration cycle2. First, the evaporator absorbs Heat as refrigerant evaporates. Next, the compressor increases refrigerant pressure and temperature. Then, the condenser rejects Heat as the refrigerant condenses. Finally, the expansion valve reduces pressure, preparing refrigerant to absorb Heat again.

The Thermodynamic Process in Detail

Le refrigeration cycle2 is a heat pump that moves thermal energy from your process to the Environment. What fascinates me most is how this process manipulates the physical properties of refrigerants to create cooling.

Phase 1: Evaporation (Heat Absorption)

In the evaporator, the cold, low-pressure refrigerant (typically at 4-7°C/40-45°F) absorbs Heat from the process water. This heat transfer causes the refrigerant to evaporate completely, changing from a liquid to a vapor.

The refrigerant can absorb significantly more Heat than water due to its low boiling point and high latent Heat of vaporization. This makes it an excellent medium for heat transfer in industrial applications.

Phase 2: Compression

During compression, the refrigerant enters the compressor as a low-pressure vapor. The compressor adds mechanical energy to the refrigerant, increasing its pressure and temperature to 50-60°C (120-140°F) above ambient conditions.

This compression stage accounts for most of the la consommation d'énergie1 in a chiller system. That’s why variable speed drives that optimize compressor operation at part-load conditions can reduce annual energy costs by 30% or more.

Phase 3: Condensation (Heat Rejection)

The high-pressure, high-temperature refrigerant vapor in the condenser releases Heat to the ambient air or water. As it cools, it changes from a gas to a liquid while maintaining high pressure.

Optimal condenser water temperature is typically 29.4°C (85°F) or lower for water-cooled systems. My testing has shown that lowering the entering condenser water temperature by just 1°F can improve efficiency by 1-1.5%.

Phase 4: Expansion

After condensation, the high-pressure liquid refrigerant passes through the expansion valve, which creates a sudden pressure drop. This pressure reduction causes some refrigerant to flash into vapor, dramatically cooling the remaining liquid through auto-refrigeration.

The refrigerant leaves the expansion valve as a cold, low-pressure mixture of liquid and vapor at approximately 4-7°C (40-45°F), ready to begin the cycle again in the evaporator.

What Factors Influence Chiller Efficiency and Performance?

Plant managers frequently report unexplained increases in la consommation d'énergie1 or inability to maintain setpoint temperatures. Without understanding the key performance factors, they’re essentially operating blind.

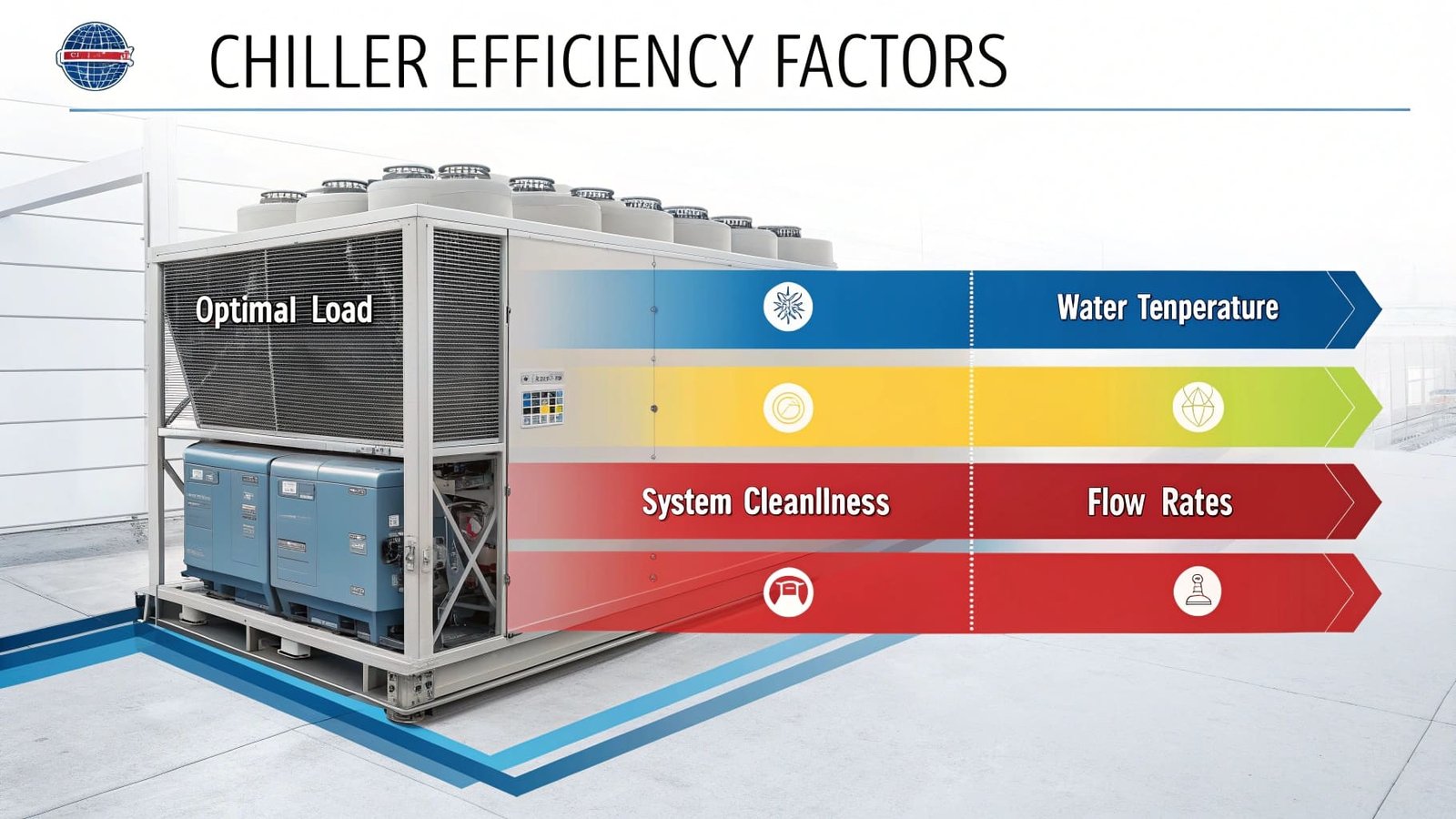

Chiller efficiency is measured by Coefficient of Performance (COP)3, typically ranging from 3.5 to 7.0, with higher values indicating better efficiency. Research shows optimal efficiency occurs at 70-75% load with properly maintained systems. Key factors include condenser water temperature, refrigerant charge, water treatment, and proper flow rates.

Load Conditions and Optimal Operation

In my experience designing and optimizing chillers, I’ve found that most systems operate most efficiently at around 70-75% of their maximum load. This finding has helped us design systems with multiple chillers that can be staged to keep individual units operating in their optimal range.

Here’s how different load conditions affect performance:

| Load Percentage | Typical Efficiency | Notes |

|---|---|---|

| 100% | 90-95% of optimal | Full load is rarely the most efficient point |

| 70-75% | 100% (Optimal) | Sweet spot for most chillers |

| 50% | 85-90% of optimal | Still efficient with VSDs |

| 25% | 60-70% of optimal | Efficiency drops significantly |

Water Temperature Management

The most crucial factor in chiller efficiency4 is proper temperature management for process and condenser water.

For every 1°F increase in chilled water temperature (at constant load), efficiency improves by:

- -1-2% for constant speed chillers

- 2-4% for variable speed chillers

Conversely, every 1°F increase in condenser water temperature above design reduces efficiency by 1-2%. When I help clients optimize their systems, we focus heavily on cooling tower performance to minimize condenser water temperatures.

Water Treatment and System Cleanliness

Poor water treatment5 is one of the most common and costly efficiency problems I encounter. The numbers are startling:

- Fouling and scaling can reduce efficiency by 10-35%

- Microbiological growth can reduce heat transfer by 15% or more

- Combined scale and iron deposits can cause an additional 10-20% efficiency loss

Our maintenance protocols always include regular water testing and treatment, which typically pays for itself within months through energy savings.

Flow Rates and System Design

Maintaining proper flow rates is critical for efficient operation:

- Below 3 ft/s causes laminar flow and poor heat transfer

- Above 12 ft/s can cause erosion and system wear

- Maintaining >90% of design flow ensures optimal efficiency

Industrial chillers come in two main system designs:

- Open-loop systems – Expose water to outside environments, suitable for large-tonnage applications but more prone to contamination

- Closed-loop systems – Sealed systems with less maintenance requirements, ideal for smaller applications and cleaner environments

Refrigerant Management and Environmental Considerations

Proper refrigerant charge is essential for optimal operation. Modern refrigerants also have varying environmental impacts:

| Refrigerant | ODP (Ozone Depletion) | GWP (Global Warming) | Common Applications |

|---|---|---|---|

| R-134a | 0 | 1430 | Medium-temp applications |

| R-410A | 0 | 1725 | Common in Europe and Asia |

| R-717 (Ammonia) | 0 | <1 | Industrial, environmentally friendly |

| R-32 | 0 | 675 | Newer, lower GWP option |

At Kaydeli, we’ve been transitioning to lower GWP refrigerants while maintaining or improving efficiency. This aligns with global environmental regulations and reduces long-term operating costs.

Maintenance Practices and Standards

Regular maintenance is not just about preventing breakdowns—it directly impacts energy efficiency. Our data shows poorly maintained chillers can consume 30% more energy than well-maintained units.

We recommend following standards like ASHRAE 90.1 and adhering to a structured maintenance program:

- Weekly visual inspections and log reviews

- Monthly water treatment5 checks

- Quarterly oil analysis for larger systems

- Annual comprehensive performance evaluation

Conclusion

Industrial chillers work through a carefully engineered refrigeration cycle, moving heat from your process to the environment while maintaining precise temperature control. By understanding these principles and optimizing the key performance factors, you can achieve 30% or more energy savings while extending equipment life and improving reliability.

-

Reducing energy consumption is vital for cost savings and sustainability. Discover strategies to enhance chiller efficiency and lower energy use. ↩ ↩ ↩

-

Understanding the refrigeration cycle is crucial for optimizing chiller performance and energy efficiency. Explore this link to deepen your knowledge. ↩ ↩ ↩ ↩

-

The COP is a key metric for evaluating chiller efficiency. Learn more about how it impacts energy savings and performance. ↩

-

Understanding chiller efficiency is crucial for optimizing energy use and reducing costs. Explore this link for in-depth insights. ↩

-

Effective water treatment is vital for maintaining chiller efficiency. Discover best practices and solutions to enhance performance. ↩ ↩