Is ensuring food quality and safety keeping you up at night? Spoilage, bacterial growth, and failing to meet regulations can cripple a food processing business. Reliable refrigeration isn’t just helpful; it’s the backbone of your operation, crucial for extending shelf life and maintaining the integrity of the food supply chain.

Food processing refrigeration systems are crucial because they precisely control temperature and humidity. This slows spoilage, inhibits harmful bacteria growth (below 5°C/41°F is key), maintains product texture and nutritional value, significantly extends shelf life, and ensures strict food safety standards compliance.

In my role at Kaydeli, I often talk with Operations Managers like James Carter. They understand the stakes are high in the food industry, whether processing meat, dairy, fruits, or vegetables. Maintaining the cold chain isn’t just about keeping things cool; it’s about protecting consumers, preserving the quality customers expect, reducing waste, and running an efficient, compliant business. The technology has evolved significantly, and choosing the right system is more critical than ever. Let’s explore what these systems are and why they are so vital.

What are Food Processing Refrigeration Systems?

Struggling to understand the nuts and bolts of industrial cooling? SPut food processing refrigeration systems1 are specialized industrial systems designed to remove heat from food products and the spaces where they are processed, stored (cold storage), or transported. Their core purpose is preservation – slowing down natural decay processes and inhibiting microbial growth to keep food safe and quality from the farm or factory to the consumer’s table, essential in sectors like meat, poultry, dairy, and fruit/vegetable processing.

The journey from simple ice harvesting centuries ago to today’s sophisticated systems has been remarkable. Early pioneers like Carl von Linde developed mechanical refrigeration in the late 19th century, revolutionizing food preservation. Modern systems, while based on the same core principles, are far more advanced, efficient, and tailored to the specific needs of the food industry.

At the heart of most systems (especially the common mechanical vapor-compression type) are four key components working in a continuous cycle:

- Compressor: Think of this as the engine or heart of the system. It takes in low-pressure refrigerant vapor and compresses it into a high-pressure, high-temperature vapor. This requires significant energy input.

- Condenser: This component’s job is to reject heat from the system. The hot, high-pressure refrigerant vapor flows through the condenser (often coils with fans or using water), releases its heat to the surrounding air or water, and condenses into a high-pressure liquid.

- Expansion Valve (or Metering Device): This valve creates a pressure drop. The high-pressure liquid refrigerant flows through it, causing a rapid decrease in pressure and temperature, turning it into a cold, low-pressure mixture of liquid and vapor.

- Evaporator: This is where the actual cooling happens inside the refrigerated space (e.g., cold room, freezer, process chiller). The cold, low-pressure refrigerant flows through the evaporator coils. As the warmer air from the refrigerated space passes over these coils, the refrigerant absorbs the heat, boils, and turns back into a low-pressure vapor. This cooled air is then circulated in the space. The low-pressure vapor then returns to the compressor to start the cycle again.

Understanding these basics helps appreciate how these industrial refrigeration2 systems work tirelessly to protect our food supply. I remember explaining this cycle to a client once using the analogy of how their own facility’s AC worked, just on a much larger, more robust, and precisely controlled scale – it clicked instantly for them.

Types of Refrigeration Systems Used in Food Processing

Feeling lost in the different refrigeration technologies? While the goal is always cooling, the methods can vary significantly based on the application, scale, efficiency needs, and available energy sources. Choosing the right type is critical for performance and cost-effectiveness. Let’s look at the main categories used in the food industry.

1. Mechanical Vapor-Compression Refrigeration

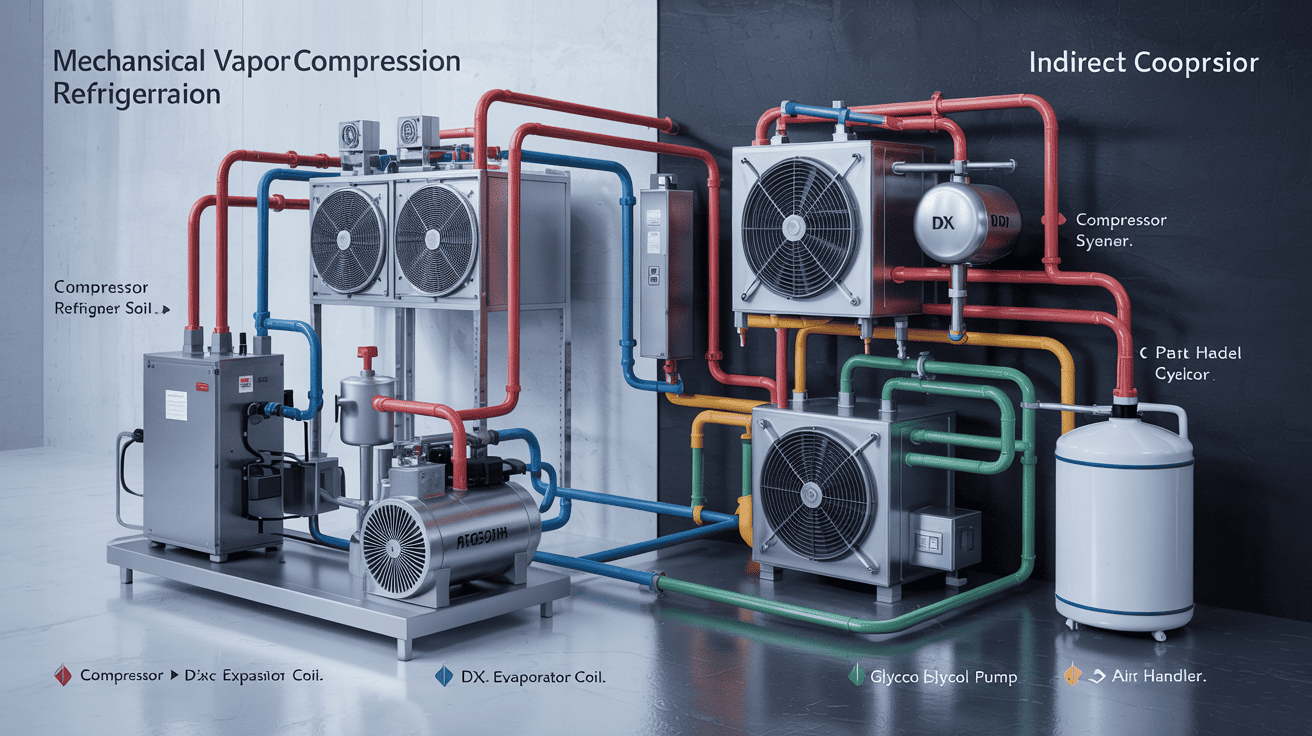

This is the most common type used in food processing, from small commercial refrigeration3 units to massive industrial plants. It relies on the vapor-compression cycle described earlier using various refrigerants. Within this category, there are two main approaches to delivering the cooling:

- Direct Expansion (DX) Systems: The refrigerant evaporates directly within the coils located in the space or equipment being cooled (e.g., inside the evaporator of a walk-in cooler). This offers efficient heat transfer and rapid response but means refrigerant lines run into the cooled space, carrying a potential (though manageable) leak risk.

- Indirect Cooling Systems (e.g., Brine or Glycol Systems): These use the primary refrigerant cycle to cool a secondary liquid (like saltwater brine or a glycol-water mixture). This cooled secondary liquid is then pumped to the point of use (e.g., air handlers in a large cold storage room, jackets on process tanks). This approach keeps the primary refrigerant contained, enhancing safety, especially with refrigerants like ammonia, and is suitable for distributing cooling over longer distances. However, it introduces an extra heat exchange step, which can slightly reduce overall efficiency compared to a DX system.

2. Absorption Refrigeration

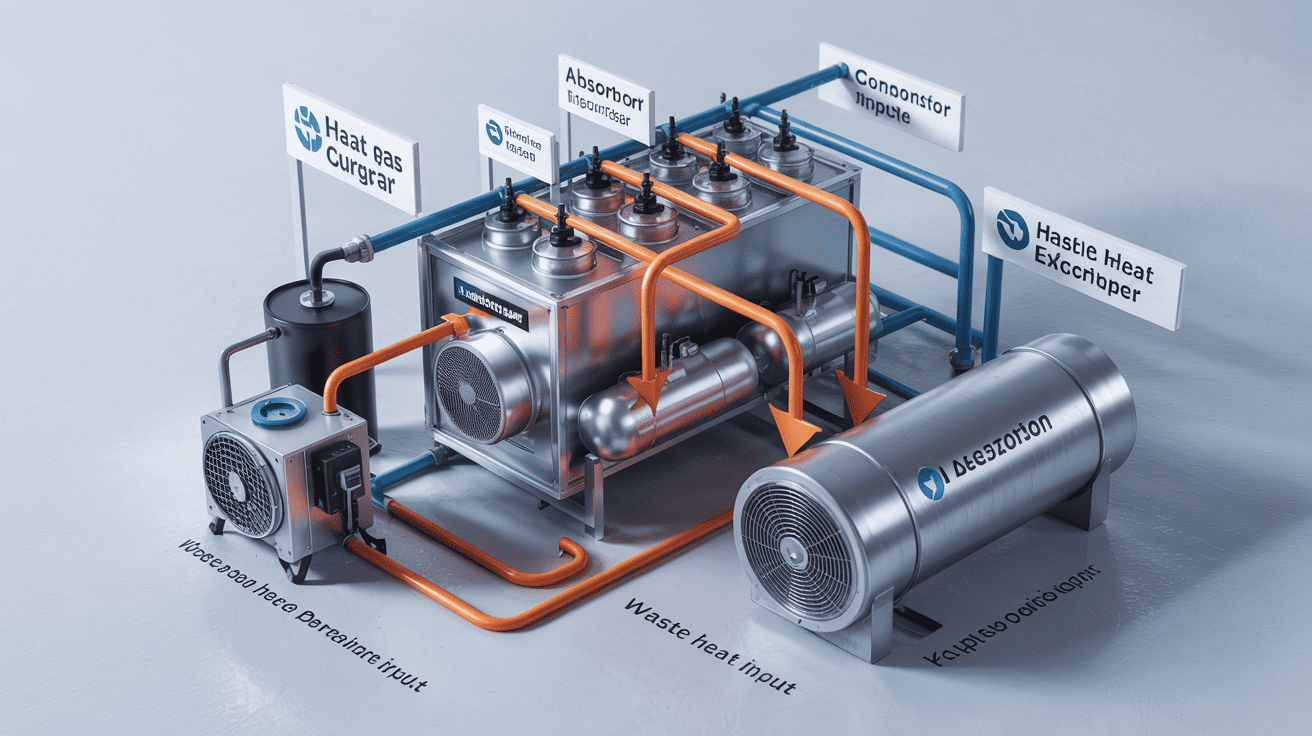

Unlike compression systems that use mechanical energy (electricity) to drive the process, absorption refrigeration primarily uses heat energy.

- How it works: It uses a heat source (like natural gas, steam, or even waste heat from other industrial processes) to drive a thermodynamic cycle involving an absorbent fluid and a refrigerant (often ammonia and water).

- Applications: Less common than compression systems in food processing due to generally lower efficiency, but can be very cost-effective in facilities with a cheap or readily available heat source.

3. Cryogenic Refrigeration

This method uses expendable cryogens – liquid substances at extremely low temperatures – to achieve rapid freezing or chilling.

- How it works: Liquid nitrogen (LN₂) at -196°C (-320°F) or liquid/solid carbon dioxide (CO₂) at -78.5°C (-109.3°F) comes into direct or indirect contact with the food product. The cryogen absorbs massive heat as it changes phase (liquid to gas, solid to gas), quickly freezing the product.

- Applications: Primarily used for Individually Quick Freezing (IQF) of small, high-value products like berries, shrimp, diced meats, or baked goods. The rapid freezing minimizes ice crystal formation, preserving product texture, flavor, and nutritional value exceptionally well compared to slower methods. Also used for chilling during mixing/grinding (e.g., CO₂ snow in meat processing). While operational costs are higher due to the consumable cryogen, it offers unique quality benefits for specific premium products like seafood and prepared foods.

Ammonia (NH₃) vs. CO₂ (R-744) Systems (Common Mechanical Compression Refrigerants)

Within mechanical compression systems, refrigerant is a significant decision point, especially for larger industrial applications. Ammonia (R-717) and Carbon Dioxide (R-744) are two leading "natural" refrigerants gaining prominence over older synthetic options due to environmental regulations. I often help clients weigh their pros and cons:

| Fonctionnalité | Ammonia (NH₃ / R-717) | Carbon Dioxide (CO₂ / R-744) |

|---|---|---|

| Efficacité | Highly efficient thermodynamic properties, especially in medium/high temps. | Good efficiency, particularly effective at very low temperatures (e.g., deep freezing). Transcritical systems needed for high ambient temperatures can impact efficiency. |

| Environmental | Zero ODP (Ozone Depletion Potential), Zero GWP (Global Warming Potential). Natural refrigerant4. | Zero ODP, GWP = 1 (baseline). Excellent environmental profile. Natural refrigerant4. |

| Safety | Toxic at relatively low concentrations. Flammable under certain conditions. Requires strict safety protocols (ventilation, leak detection, steel piping). Restricted use in some occupied spaces. | Non-toxic, non-flammable. Safer for personnel and occupied spaces. |

| Operating Pressure | Moderate pressures. | Very high pressures (significantly higher than ammonia or HFCs). Requires specialized components, piping, and technician expertise. |

| Material Comp.. | Corrosive to copper and brass. Requires steel piping and components. | Not corrosive to common metals like copper and steel. |

| Refrigerant Cost | Relatively inexpensive. | Generally inexpensive, but system component costs are higher due to pressure requirements. |

| System Cost | Moderate to high, driven by safety requirements and steel components. | Can be higher initially due to high-pressure components and specialized design needs. |

| Best Suited For | Large industrial cold storage, food processing plants (meat, dairy), breweries where safety can be managed (often in indirect systems). | Supermarkets (often cascade or transcritical systems), food processing (especially low-temp freezing), applications where toxicity/flammability are major concerns, or limited space. |

Choosing between these involves balancing efficiency, safety, cost, regulatory compliance, and the specific temperature requirements of the food processing application.

Why Refrigeration is Critical in Food Processing

Food needs cooling, but adequate refrigeration’s impact goes far beyond preventing milk from souring. For Operations Managers like James Carter, understanding why it’s critical helps justify investment and prioritize system performance. It boils down to three interconnected pillars: Safety, Quality, and Compliance.

1. Ensuring Food Safety

This is paramount. Refrigeration is one of the most effective tools to combat foodborne illness.

- Slowing Bacterial Growth: Most harmful bacteria (like Salmonella, Listeria, E. coli) thrive in the "Temperature Danger Zone," typically defined by the FDA as between 40°F and 140°F (4°C and 60°C). Proper refrigeration below 40°F (4°C) – with many experts and bodies like the WHO recommending storage below 5°C (41°F) – significantly slows down or stops the multiplication of these pathogens. Freezing below 0°F (-18°C) stops growth altogether (though it may not kill all bacteria), which is essential for frozen meat storage.

- Preventing Spoilage: Refrigeration also slows the growth of spoilage microorganisms (bacteria, yeasts, molds) that cause food to rot, develop off-odors, change texture, and become inedible, even if not immediately dangerous.

- Slowing Enzyme Reactions: Cold temperatures inhibit the natural enzymatic activity within food, preventing undesirable changes like enzymatic browning in fruits or texture degradation.

- Consistency: Maintaining consistent, correct temperatures throughout processing, storage, and transport (the "cold chain") is essential. Temperature fluctuations can allow bacteria to multiply rapidly during temporary excursions into the danger zone. I remember a client dealing with inconsistent product safety results until we traced it back to temperature abuse during a specific processing step – upgrading that chilling process made all the difference.

2. Maintaining Food Quality

Consumers expect food to look, taste, and feel right. Refrigeration plays a huge role in preserving these sensory and nutritional attributes.

- Texture: Slow chilling and freezing (especially ultra-rapid freezing with cryogenic systems) minimize the formation of large ice crystals that can damage cell structures, leading to mushiness upon thawing. Proper refrigeration helps maintain the desired firmness or tenderness of products like meat, fish, and produce.

- Taste and Aroma: Cold temperatures slow down enzymatic and chemical reactions that cause flavors and aromas to degrade or develop undesirable "off-notes."

- Appearance: Refrigeration helps preserve the natural color of foods and prevents wilting or drying out by maintaining appropriate humidity levels (critical for fresh produce).

- Nutritional Value: While some nutrient loss is inevitable over time, refrigeration significantly slows the degradation of vitamins and other sensitive nutrients compared to storage at ambient temperatures.

3. Extending Shelf Life & Reducing Waste

By slowing down all forms of degradation, refrigeration dramatically extends the usable life of perishable foods.

- Longer Storage: Shelf life can increase from days to weeks (refrigerated) or months (frozen), enabling longer transport distances and reducing the frequency of spoilage-related waste.

- Supply Chain Support: This extended life is fundamental to modern global food supply chains, allowing products to reach consumers far from their origin.

4. Meeting Regulatory Compliance

The food industry is heavily regulated for very good reasons. Failing to meet standards can result in hefty fines, forced recalls, facility closures, and irreparable damage to a brand’s reputation.

- HACCP Plans5: Hazard Analysis and Critical Control Points (HACCP) plans are mandatory for many food sectors. Refrigeration temperatures are almost always identified as Critical Control Points (CCPs) that must be monitored and documented rigorously.

- Agency Standards: Agencies like the FDA, USDA, and international bodies set specific temperature requirements for different food categories (e.g., dairy often requires 0-4°C).

- Record Keeping: Regulations often require detailed logs of temperature monitoring data. Modern refrigeration systems with integrated monitoring make this much easier and more reliable.

Adequate refrigeration isn’t just an operational choice; it’s a fundamental requirement for producing safe, high-quality food that meets consumer expectations and legal obligations.

Key Factors to Consider When Choosing a Refrigeration System

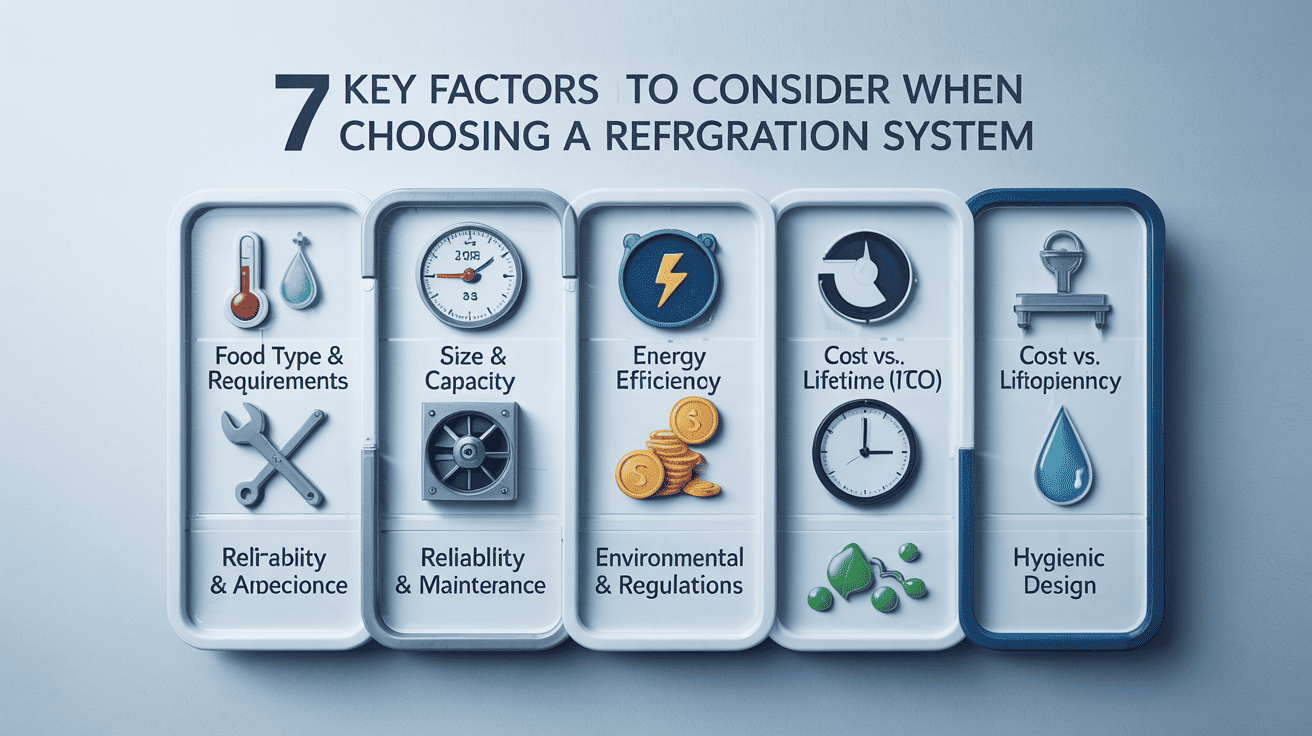

Selecting a new or replacement refrigeration system is a significant decision for any food processing facility. Balancing performance, cost, and compliance is key for someone like James Carter. Rushing this decision or focusing only on the upfront price tag can lead to long-term headaches. Here are the critical factors I always advise clients to evaluate thoroughly:

1. Food Type and Specific Requirements

Different foods have vastly different needs.

- Temperature: What specific temperature range is required (chilling vs. freezing)? Is precise control critical?

- Humidity: This is often overlooked but crucial. Fresh produce typically requires high humidity (85-95% RH) to prevent wilting and moisture loss, while processed meats might need lower humidity to inhibit surface microbial growth. The system must maintain the appropriate humidity level for the specific product.

2. Size and Capacity Requirements

The system must be able to handle the cooling load.

- Calculating the Load: This involves determining the total heat from the product, processes, infiltration (doors, air leaks), equipment (motors, lights), and transmission through walls/roof.

- Matching Capacity: The system’s cooling capacity (BTUs/hour or kW) must meet the peak load plus a safety margin (10-20%). Accurate load calculation by experienced engineers is vital to avoid under-sizing (compromising safety) or over-sizing (wasting energy and capital).

3. Efficacité énergétique6

Refrigeration is energy-intensive. Improving efficiency reduces OpEx and environmental impact.

- System Design & Components: Look for high EER/COP/IPLV ratings, efficient compressor types (e.g., screw, scroll), appropriately sized heat exchangers, and sound insulation.

- Variable Speed Drives (VSDs): Using VSDs on compressors and fans allows the system to match output to load precisely, saving significant energy (often 20-50%) compared to fixed-speed systems.

- Advanced Controls: Features like electronic expansion valves (EEVs), EC (electronically commutated) fans, optimized defrost cycles, and floating head pressure controls enhance efficiency.

4. Reliability and Maintenance Needs

Downtime is extremely costly.

- System Robustness: Choose systems with high-quality components designed for industrial duty cycles.

- Maintenance Requirements: Consider the complexity and frequency of required maintenance. Factor in the cost and availability of qualified technicians (especially for specialized systems like high-pressure CO₂ or ammonia).

- Preventative Maintenance: A robust preventative maintenance plan is essential for longevity and preventing unexpected failures.

5. Cost: Upfront (CapEx) vs. Lifetime (TCO)

Look beyond the initial purchase price.

- Total Cost of Ownership (TCO)7: Includes CapEx plus lifetime OpEx (energy, maintenance, water, refrigerant, potential downtime).

- Payback Period: A more efficient system may cost more upfront but offer a quick payback through energy savings. Analyze the TCO over the system’s expected lifespan (15- 25+ years).

6. Environmental Impact and Regulations

Regulations are tightening globally.

- Refrigerant Choice: Prioritize low-GWP options like ammonia (NH₃), CO₂ (R-744), or Hydrocarbons (HCs like R-290 propane in smaller systems) to comply with regulations (e.g., US AIM Act, EU F-Gas) phasing down HFCs.

- Leak Prevention & Detection: Essential for environmental responsibility and system efficiency.

- Sustainability Goals: Align system choice with corporate sustainability targets.

7. Hygienic Design

Crucial in food processing to prevent contamination.

- Cleanability: Surfaces should be smooth, accessible, and easy to clean thoroughly. Avoid crevices where bacteria can hide.

- Materials: Use food-grade, corrosion-resistant materials (like stainless steel) where contact with food or harsh cleaning chemicals is possible.

- Drainage: Ensure proper drainage to prevent standing water.

Making the correct choice involves carefully weighing all these factors, often with the help of experienced refrigeration engineers who understand the specific demands of the food processing industry.

Innovations and Future Trends in Food Processing Refrigeration

The world of industrial refrigeration isn’t standing still! Driven by the need for greater efficiency, enhanced safety, stricter environmental regulations, and better control, exciting innovations are constantly emerging. For Operations Managers like James, staying aware of these trends is key to future-proofing their facilities and staying competitive. Here’s a look at what’s shaping the future:

1. Dominance of Eco-Friendly Natural Refrigerants

The phase-down of high-GWP HFCs is accelerating the shift to natural alternatives:

- CO₂ (R-744): Expanding rapidly, especially with innovations like transcritical booster systems and ejector technology improving efficiency in warmer climates.

- Low-Charge Ammonia (NH₃): Designs significantly reducing the ammonia inventory minimize safety risks while retaining high efficiency, making ammonia viable for more applications via packaged systems.

- Hydrocarbons (HCs): Propane (R-290) is increasingly used in smaller self-contained commercial units due to its efficiency, governed by strict charge limits for safety.

2. Smart Refrigeration Systems and IoT Integration

IoT is revolutionizing management:

- Enhanced Monitoring & Data Analytics: Continuous tracking of all parameters provides real-time insights, optimizes performance, aids compliance reporting, and enables cloud-based management.

- Predictive Maintenance: Algorithms analyze data to predict failures before they happen, allowing proactive scheduling and preventing costly downtime. I’ve seen clients save thousands by catching issues early thanks to these alerts.

- Remote Diagnostics & Control: Reduces site visits and allows authorized remote adjustments.

3. Advanced Cooling and Chilling Methods

Techniques offering faster cooling and better quality preservation:

- Spray Cooling / Immersion Cooling: Using liquid sprays or baths for rapid, uniform cooling, especially for poultry or cooked products.

- Vacuum Cooling: Rapidly cools porous products like leafy greens or baked goods by evaporating moisture under vacuum.

- Deep Chilling / Superchilling: Cooling products to just below their initial freezing point (-0.5°C to -2°C) without forming significant ice, extending shelf life beyond standard chilling while maintaining fresh-like quality.

4. Improved Insulation and Door Technologies

Reducing heat ingress is key to efficiency:

- Advanced Insulation: Higher R-value materials like PIR foam and potentially Vacuum Insulated Panels (VIPs) for space-constrained areas.

- High-Speed Doors: Rapid roll-up or bi-parting doors minimize air exchange during entry/exit from cold rooms, significantly reducing infiltration load compared to slow-moving doors.

5. Focus on Sustainability and Energy Saving Technologies

System-level optimization:

- Heat Recovery: Capturing condenser waste heat for hot water or space heating.

- Optimized Defrost: Demand-based defrost cycles instead of fixed timers.

- Efficient Condensing: Adiabatic or evaporative condensers boost efficiency in hot climates.

- Thermal Energy Storage (TES): Using ice banks or phase change materials to shift energy use to off-peak times.

6. Emerging Non-Traditional Technologies (Future Potential)

While still primarily in research and development, these hold future promise:

- Magnetic Refrigeration: Uses the magnetocaloric effect for potentially higher efficiency and no traditional refrigerants.

- Thermoacoustic Refrigeration: Uses sound waves to generate cooling.

- Stirling Cycle Refrigeration: A long-known thermodynamic cycle being revisited for specialized cooling applications.

These are not mainstream but represent future breakthroughs for even greener and more efficient cooling.

These innovations are making food processing refrigeration systems more innovative, greener, and more reliable, helping businesses like James Carter’s meet today’s and tomorrow’s challenges.

Conclusion

Selecting and maintaining the right food processing refrigeration system is fundamental. It directly impacts food safety, food quality, operational efficiency, shelf life, waste reduction, and regulatory compliance – core responsibilities for any food business. Embracing efficient designs, reliable components, and appropriate refrigeration solutions, including sustainable natural refrigerants)8 and innovative technologies, ensures you not only meet today’s demands but also future-proof your operations in an evolving industry. Consulting with refrigeration experts can help navigate the complexities and find the optimal industrial refrigeration system for your specific needs.

-

Explore this link to understand how these systems enhance food safety and extend shelf life, crucial for any food business. ↩

-

Learn about the mechanics of industrial refrigeration and its importance in maintaining food quality and safety. ↩

-

Discover the various commercial refrigeration options and how they can optimize your food processing operations. ↩

-

Explore the advantages of natural refrigerants, including their environmental impact and efficiency, to make informed choices for your refrigeration needs. ↩ ↩

-

Understanding HACCP plans is crucial for ensuring food safety and compliance in the food industry. Learn how they can protect your business. ↩

-

Discover strategies to enhance energy efficiency in refrigeration, reducing operational costs and environmental impact while maintaining performance. ↩

-

Understanding TCO helps make informed decisions about refrigeration investments, ensuring long-term savings and efficiency. ↩

-

Exploring natural refrigerants can reveal eco-friendly options that enhance efficiency and comply with regulations, crucial for sustainability. ↩