Neglected cooling systems deteriorate silently, causing unexpected breakdowns that halt production and trigger costly emergency repairs. Companies lose millions when their temperature control fails at critical moments.

Effective industrial cooling maintenance combines regular inspections, component cleaning, fluid checks, performance monitoring, and scheduled professional servicing. This systematic approach prevents failures, extends equipment life, improves efficiency, and significantly reduces long-term operating costs.

After 15 years in the refrigeration industry, I’ve witnessed countless preventable cooling system failures. The difference between reliable operation and expensive downtime often comes from simple maintenance practices. Let me share what I’ve learned to help keep your operations running smoothly.

How Should You Perform Routine Inspections for Industrial Cooling Systems?

Skipping regular inspections leaves minor issues undetected until they evolve into system-wide failures. I’ve seen minor problems become production-stopping emergencies within days when left unchecked.

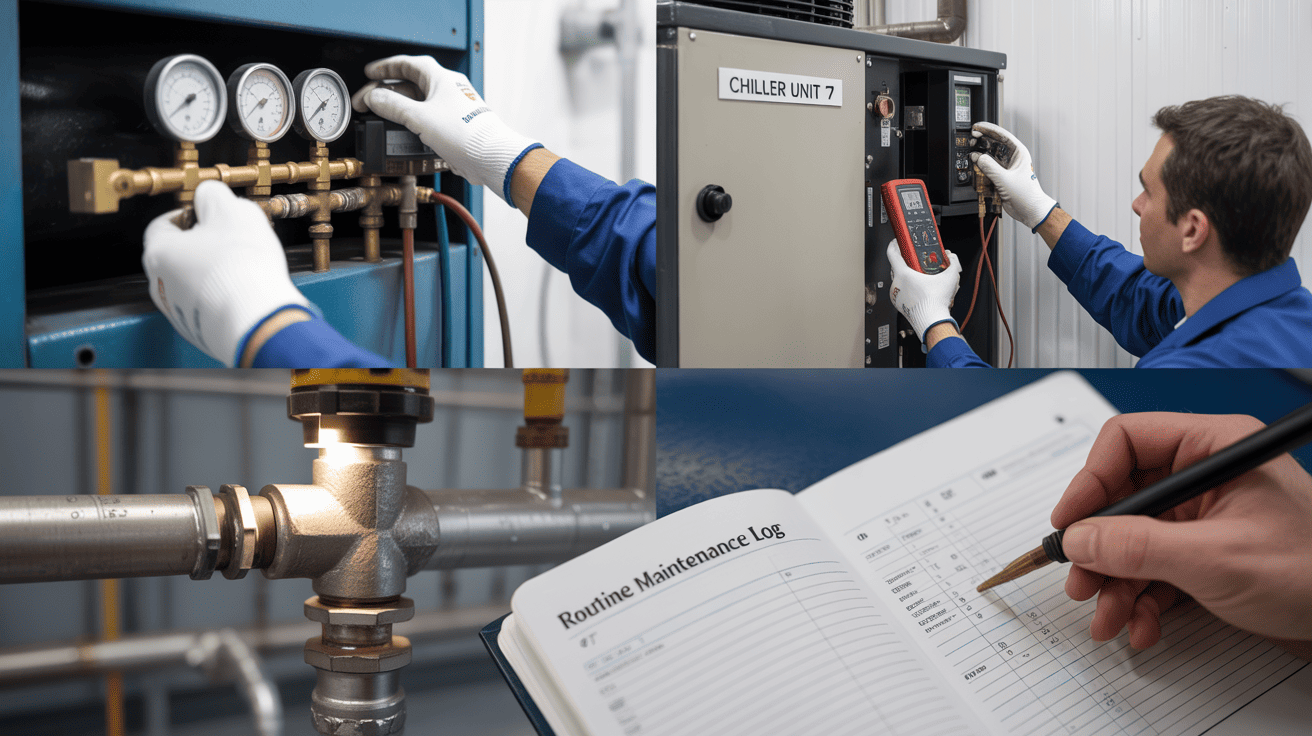

Effective routine inspections include examining refrigerant levels, checking for leaks, inspecting electrical connections, monitoring operating pressures, and temperatures. Your maintenance team should perform daily visual checks, weekly component inspections, and quarterly comprehensive evaluations while documenting findings in a dedicated log.

I remember visiting a pharmaceutical client whose production line had stopped due to a cooling failure. Their system had been showing warning signs for weeks – slightly elevated temperatures, unusual noises – but without a formal inspection process, these signals were missed. The eventual breakdown cost them three days of production and over $200,000 lost product.

Your inspection routine should be systematic and thorough. I recommend creating a standardized checklist covering these critical areas:

Key Inspection Points for Industrial Cooling Systems

| Component | What to Check | Warning Signs | Action Required |

|---|---|---|---|

| Refrigerant System | Pressure readings, sight glass clarity, pipe temperatures | Bubbles in sight glass, unusual pressure readings | Document readings, schedule leak test if suspicious |

| Condenser/Evaporator | Coil cleanliness, fin condition, fan operation | Bent fins, debris buildup, uneven frost patterns | Clean coils, straighten fins, verify airflow |

| Water Systems | Flow rates, temperature differential, water quality, pH, conductivity | Scale deposits, restricted flow, improper pH | Clean strainers, test water, adjust treatment |

| Electrical Components | Connection tightness, insulation condition, control accuracy | Discoloration, burning smell, erratic operation | Tighten connections, replace damaged components |

| Compressor | Oil levels, discharge temperatures, vibration, noise | Excessive noise, high discharge temperature | Check oil, verify refrigerant charge, analyze vibration |

Based on industry standards from ASHRAE guidelines, your inspection frequency should follow this pattern:

-

Daily Inspections: Visual checks for leaks, unusual noises or vibrations; monitor water levels, temperatures, and pressure gauges; ensure fan operation.

-

Weekly Inspections: Inspect coils and motor temperatures, test for leaks, check control operations, and assess water quality.

-

Quarterly Inspections: Conduct thorough exterior inspections, clean water strainers, lubricate bearings, and test water quality parameters.

-

Annual Inspections: Perform detailed mechanical and electrical component inspections, clean water systems, and adjust water treatment.

When we implemented this inspection system at a food processing plant in Guangdong, they identified and resolved eight potential failure points in the first month alone. According to Transtherm’s recommendations, facilities in dusty environments should increase their condenser cleaning frequency to weekly. At the same time, those with variable loads should monitor performance metrics more frequently to catch efficiency losses early.

What Preventive Maintenance Schedule Works Best for Industrial Chillers?

Many facilities attempt to maintain cooling systems with sporadic, intensive service sessions. This approach leaves equipment vulnerable between services and often misses developing issues.

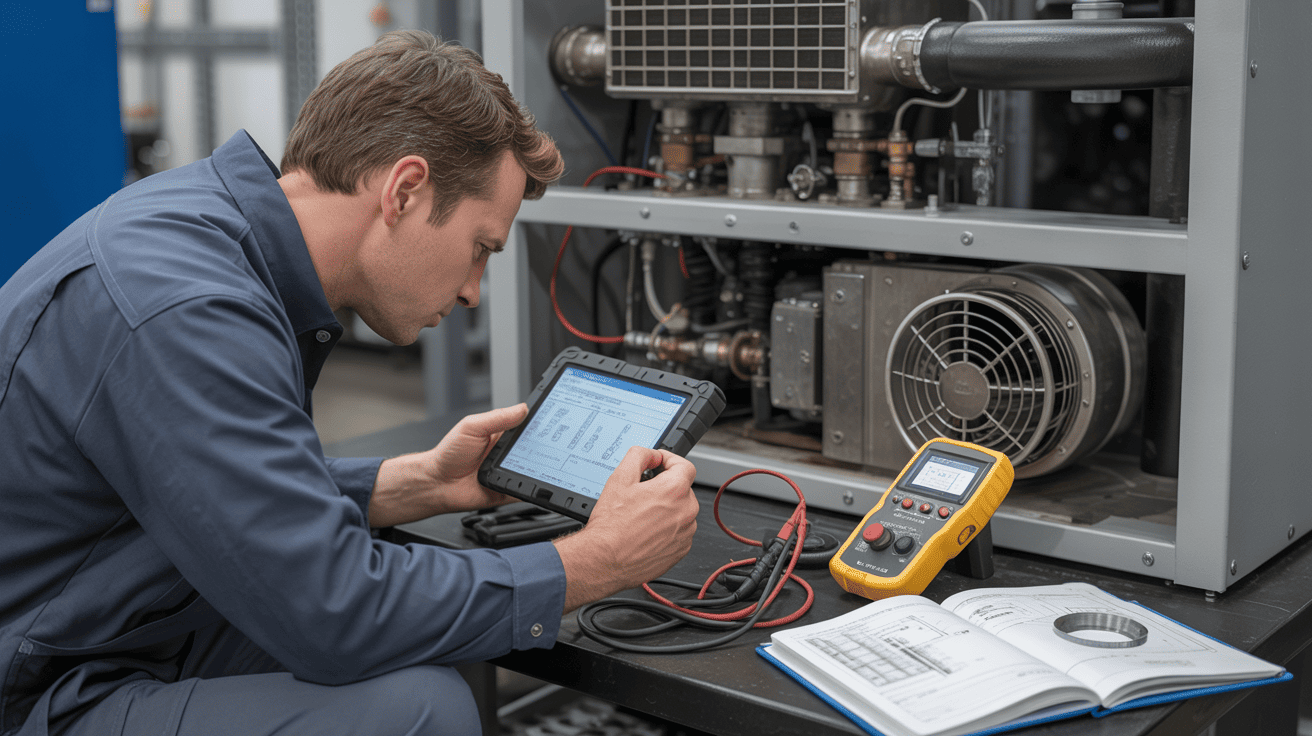

The ideal preventive maintenance schedule1 includes daily operational logs, weekly system inspections, quarterly comprehensive evaluations following manufacturer guidelines, semi-annual load balance reviews, and annual professional servicing. This layered approach ensures all system aspects receive appropriate attention while extending equipment life and reducing energy consumption.

Early in my career, I consulted for a textile manufacturer who complained about excessive energy costs and frequent component failures. Their maintenance consisted solely of reacting to problems and an annual shutdown inspection. After implementing a structured maintenance program based on Cold Shot Chillers’ recommendations, they reduced their energy consumption by 23% and virtually eliminated emergency service calls.

The key to effective maintenance is consistency and appropriate task distribution. Here’s the framework I recommend based on what’s worked best for our clients across different industries:

Daily Maintenance Tasks (5-10 minutes)

Your operators should perform these quick checks during regular rounds:

- Visual inspection for leaks or unusual conditions

- Verification of operating temperatures and pressures against targets

- Brief listening check for abnormal sounds or vibrations

- Confirmation that control systems display proper readings

- Logging operating conditions for trend analysis (temperatures, flow rates, pressures, fluid levels)

We installed simple visual indicators on a cooling system for an electronics manufacturer in Shenzhen. These "at-a-glance" gauges allowed operators to spot potential issues immediately without specialized knowledge. Within three months, they caught five developing problems before they affected production.

Weekly Maintenance Tasks (30-60 minutes)

These more detailed checks should be performed by maintenance personnel:

- Cleaning of external air filters and strainers

- Inspection of belt tension and alignment

- Verification of oil levels in compressors

- Testing of safety controls and alarms

- Recording and trending of performance data

- Inspection of evaporator and condenser coils

- Assessment of water quality in cooling systems

One automotive parts manufacturer I worked with began plotting their weekly performance data on simple charts, as UpKeep’s maintenance guide recommended. This visual tracking helped them identify a gradual decrease in efficiency that indicated scale buildup in their condenser water system before it became critical.

Quarterly Maintenance Tasks (2-4 hours)

These more involved procedures follow manufacturer guidelines and may require brief system adjustments:

- Chemical treatment of cooling water systems

- Cleaning of condenser coils

- Inspection of electrical controls and connections

- Calibration check of sensors and control systems

- Vibration analysis of rotating equipment

- Checking refrigerant leaks, oil levels, pressures, and temperatures

- Inspecting motor voltages, amps, starters, relays, and contactors

Semi-Annual and Annual Maintenance

These comprehensive services often require scheduled downtime and specialized technicians:

- Inspection of load balances and limits (semi-annual)

- Complete system performance evaluation

- Refrigerant circuit testing and adjustment

- Oil analysis for compressors

- Heat exchanger cleaning and inspection

- Control system optimization and calibration

- Electrical system inspections

- Replacement of aging sensors, motors, or pumps

According to SafetyCulture’s maintenance guidelines, facilities implementing this layered approach typically reduce emergency service calls by 70-85% within the first year while extending equipment life by 3-7 years beyond manufacturer expectations. Computerized maintenance management systems can help automate this scheduling process for larger operations.

How Can You Troubleshoot Common Industrial Cooling System Problems?

When cooling problems occur, maintenance teams often replace expensive components without proper diagnosis. This wastes resources and frequently fails to resolve the underlying issue.

Effective troubleshooting requires a systematic approach: document all symptoms precisely, test the simplest potential causes first, isolate system components for testing, utilize proper diagnostic tools, and consult system documentation. This methodical process identifies true root causes quickly.

Last year, one of our plastic injection molding clients called about temperature fluctuations affecting product quality. Their team had already ordered a replacement compressor, assuming that was the issue. Our technician’s systematic diagnosis revealed the problem was a failing temperature sensor providing incorrect feedback to the control system – a simple ¥300 part versus a ¥30,000 compressor.

Successful troubleshooting requires understanding how components interact within the cooling system. When problems arise, follow this structured approach:

Common Cooling Tower Problems and Solutions

Based on industry experience and NTT Training guidelines, here’s how to address typical cooling tower issues:

| Problem | Possible Causes | Soluciones |

|---|---|---|

| Water temperature rises unexpectedly | Low air flow, high water flow, impeded sprinkler output | Adjust blade level, correct flow rate, repair/replace sprinkler, check leaks |

| Excessive vibration or noise | Worn motor bearings, loose fan mount, unbalanced fan | Grease/replace bearings, retighten hardware, rebalance fan |

| Lowered cooling capacity | Motor/fan stopped, lower RPM, electrical issues | Verify fuses, clear obstructions, check voltage, ensure starter serviceable |

| Water carries over specified level | Blocked filter, fast sprinkler rotation, high sprinkler | Unblock filter, adjust sprinkler speed/angle, lower sprinkler position |

| Water conductivity not in range | Dirty probe, debris in solenoid, leaks | Clean probe, ensure solenoid closes, check for leaks, adjust chemical feed |

Common Chiller Problems and Solutions

For industrial chillers, Lando Chillers recommends focusing on these key troubleshooting areas:

| Problem Category | Common Issues | Possible Causes | Soluciones |

|---|---|---|---|

| Clogging Problem | Oil clogging, ice blockage, dirty clogging | Compressor wear, moisture, dust, impurities | Replace filters, evacuate system, clean with nitrogen, ensure proper drying |

| High-Pressure Problem | High condensing pressure, low pressure, pressure oscillation | Air in system, condenser issues, refrigerant levels | Clean condenser, adjust settings, recover refrigerant, check pressure switch |

| Temperature System Problem | High exhaust temperature | High suction temperature, broken valves, low efficiency | Address intercooler efficiency, fix valves, ensure water cooling |

When a semiconductor manufacturer reported unusual noises from their process cooling system, we performed an acoustic analysis that identified a specific frequency pattern. This led to a deteriorating bearing in the condenser fan motor, allowing for scheduled replacement before catastrophic failure.

Electrical and Control System Issues

For control-related problems:

-

Check power quality:

Measure actual voltage and phase balance at the equipment terminals. Many controllers are sensitive to power fluctuations that may not affect other equipment. -

Verify sensor accuracy:

Calibrate or replace questionable sensors. I’ve seen complex troubleshooting efforts abandoned when a simple temperature sensor replacement solved the problem. -

Inspect control logic:

Review programmed parameters and control sequences. After power interruptions or maintenance, settings sometimes change unexpectedly. -

Evaluate component communication:

Modern systems rely on networks of controllers. Communication interruptions can cause erratic operation that mimics mechanical problems.

Industry standards from ASHRAE’s Refrigeration Handbook y HVAC Systems and Equipment Handbook recommend documenting all troubleshooting steps2 for future reference and analysis. This practice helped one of our clients identify seasonal patterns in their system issues, allowing for proactive maintenance before problems occurred.

Conclusión

Effective industrial cooling system maintenance combines systematic inspections, tiered preventive maintenance, and methodical troubleshooting. This comprehensive approach maximizes cooling efficiency3, extends equipment lifespan, prevents costly breakdowns, and protects production processes from temperature-related disruptions4. By following industry-proven practices from reputable sources like ASHRAE, UpKeep, and Transtherm, you can ensure your cooling systems deliver reliable performance when needed.

-

Discover the optimal preventive maintenance schedule to enhance the efficiency and longevity of your industrial chillers. ↩

-

This link will provide you with a comprehensive guide on troubleshooting steps that can prevent costly breakdowns. ↩

-

Explore this resource to learn proven strategies that enhance cooling efficiency and prolong equipment lifespan. ↩

-

Discover methods to prevent temperature-related disruptions and ensure reliable cooling system performance. ↩