Selecting the wrong industrial chiller1 can lead to inefficient cooling, excessive energy costs, and production delays. Many manufacturers struggle with inappropriate chillers that waste money and compromise operations. After helping numerous clients select cooling systems, I’ve found that understanding key selection criteria is essential for finding the perfect chiller for your needs.

Choosing the right industrial chiller requires evaluating the process fluid type, cooling temperature requirements, flow rate needs, environmental conditions, and proper sizing. The optimal chiller should be compatible with your coolant, maintain required temperatures, handle necessary flow rates, operate reliably in your environment, and offer easy maintenance access for long-term reliability.

After working with hundreds of clients across various industries, I’ve witnessed how proper chiller selection can transform production efficiency and reduce operational costs. Whether you’re cooling process machinery, food products, or electronic equipment, the right chiller makes all the difference. Let’s explore the essential considerations guiding you to the ideal cooling solution for your specific application.

What Factors Should You Consider When Sizing an Industrial Chiller?

Undersized chillers fail to meet cooling demands, while oversized units waste energy and money. Companies struggle with production delays due to inadequate cooling capacity, while others pay excessive utility bills for unnecessary power consumption.

To properly size an industrial chiller1, calculate your heat load using the formula: Heat Energy (kW) = Flow Rate (l/s) × ΔT (°C) × Specific Heat Capacity (4.2 kJ/kg K for water, 4.8 kJ/kg K for glycol). Consider environmental factors like ambient temperature and altitude, and plan for potential future expansion needs to avoid premature system replacement.

Accurate sizing is the foundation of an effective cooling system. From my experience working with manufacturing clients, I’ve found that many underestimate the complexity of proper chiller sizing. Let me break down the essential factors:

Calculating Heat Load Accurately

The most critical step in sizing a chiller is calculating the heat load correctly. The formula is straightforward but requires precise inputs:

| Component | Description | Example |

|---|---|---|

| Flow Rate | Volume of coolant circulating per second (l/s) | 2.36 l/s |

| Temperature Difference (ΔT) | Change in temperature between inlet and outlet (°C) | 5°C |

| Specific Heat Capacity | Energy needed to heat 1kg of material by 1°C (kJ/kg K) | 4.2 kJ/kg K for water |

Using this example with water as the coolant:

Heat Energy (kW) = 2.36 l/s × 5°C × 4.2 kJ/kg K = 49.6 kW

This calculation gives us the minimum capacity needed. I always recommend adding a 10-15% safety factor to account for unexpected variables, especially in manufacturing environments where conditions can change.

Environmental Considerations for Sizing

The environment where your chiller operates significantly impacts its performance. I’ve helped clients in diverse settings understand these factors:

-

Ambient Temperature: High ambient temperatures reduce air-cooled chiller efficiency. If your facility regularly experiences temperatures above 35°C, you may need to increase capacity by 10-20%.

-

Altitude: Facilities at higher elevations experience reduced air density, decreasing air-cooled chiller efficiency. Above 1000 meters, consider additional capacity.

-

Indoor vs. Outdoor Installation: Outdoor chillers need appropriate IP/NEMA ratings. For example, IP54-rated canopies can operate in harsh conditions to -45°C, but proper sizing must account for these extremes.

When I consulted for a client in a desert region, we had to significantly upsize their air-cooled system to compensate for the 45°C summer temperatures they regularly experienced. Understanding these environmental factors prevented specific performance issues.

Future-Proofing Your Investment

A common mistake I see is selecting a chiller based solely on current needs. Industrial equipment typically has a 15-20 year lifespan, and production requirements often change:

- Plan for production increases of 20-30% if expansion is anticipated

- Consider modular solutions that allow for capacity additions

- Evaluate if seasonal variations will affect your cooling requirements

One manufacturing client I worked with initially requested a 60kW chiller based on their current production. After discussing their five-year growth plan, we opted for a 75kW system to accommodate their projected 25% increase in production capacity. Three years later, they expanded as planned and avoided the significant cost of replacing their cooling system.

With these sizing considerations properly addressed, you’ll avoid the pitfalls of inadequate cooling capacity or excessive energy consumption, ensuring optimal performance and cost-efficiency for your industrial processes.

How Do Different Cooling Methods Impact Chiller Performance?

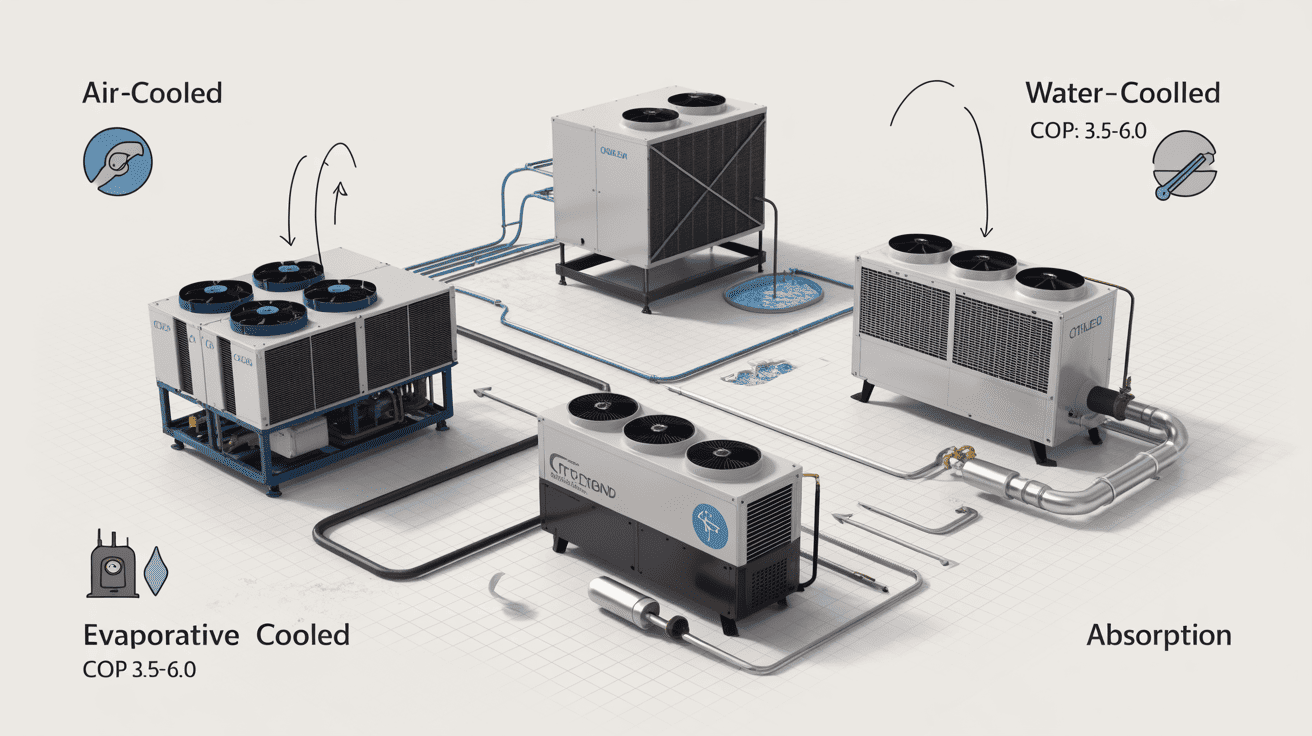

Selecting between air-cooled, water-cooled, evaporative, and absorption chillers presents a dilemma for many clients. Each offers distinct advantages in efficiency, installation costs, and maintenance requirements. Choosing incorrectly can lead to excessive operating costs or insufficient cooling in challenging environments.

The cooling method significantly impacts chiller performance. Air-cooled chillers offer a more straightforward installation with no cooling tower, but are less efficient in hot climates. Water-cooled chillers provide superior efficiency (COP 3.5-7.0) but require more maintenance. Evaporative cooled chillers offer up to 70% energy savings compared to air-cooled units, while absorption chillers use heat sources instead of electricity but have lower efficiency (COP 0.5-1.0).

Selecting the appropriate cooling method requires understanding the fundamental differences between available technologies and how they’ll perform in your specific environment. Let me share insights from my years helping clients navigate this critical choice.

Air-Cooled Systems: Simplicity and Versatility

Air-cooled chillers use ambient air to remove heat from the refrigerant, making them more straightforward to install and operate. Based on my experience with manufacturing facilities across various regions, these systems offer several advantages:

Benefits of Air-Cooled Chillers:

- No cooling tower required: Eliminates water treatment, tower maintenance, and associated costs

- Simpler installation: Requires only electrical connections and process fluid piping

- Ideal for limited water areas: Perfect for facilities with restricted water access or usage

- Versatile placement: Can be installed indoors or outdoors with proper clearances

However, these systems do have limitations. Performance decreases significantly in high ambient temperatures, with efficiency dropping as outdoor temperatures rise. They also typically have lower Coefficient of Performance (COP) ratings of 3.5-6.0 compared to water-cooled alternatives.

I recently helped a small plastics manufacturer select an air-cooled chiller for their new injection molding machines. Despite slightly higher energy costs than water-cooled options, the simplicity and reduced maintenance aligned perfectly with their limited facilities team.

Water-Cooled Systems: Maximum Efficiency

Water-cooled chillers utilize cooling towers to reject heat, offering significant efficiency advantages but requiring more complex installation:

Advantages of Water-Cooled Chillers:

- Higher efficiency: Typically 15% more efficient than air-cooled, with COP ratings of 3.5-7.0

- Consistent performance: Less affected by high ambient temperatures

- Longer lifespan: Generally experience less stress on components

- Lower operating costs: Despite higher maintenance needs, energy savings often offset these costs

The drawbacks include the need for a cooling tower, water treatment programs to prevent scaling and biological growth, and higher initial installation costs. These systems make the most sense for larger facilities with existing cooling towers or high cooling demands where efficiency savings justify the additional complexity.

For a pharmaceutical client with 24/7 cooling needs, we calculated a 3-year payback period for the additional investment in a water-cooled system based on energy savings alone, making it the superior choice despite higher initial costs.

Evaporative Cooled Chillers: The Middle Ground

Evaporative cooling combines aspects of both air and water cooling by using water evaporation to pre-cool the condenser air:

- Energy efficient: Uses up to 70% less energy than traditional air-cooled systems

- Water conservative: Uses less water than fully water-cooled systems

- Moderate maintenance: More than air-cooled but less than water-cooled

- Excellent for dry climates: Performs exceptionally well in low-humidity environments

This technology is gaining popularity as businesses seek to balance energy efficiency with water conservation. For a client in the southwestern United States, an evaporative-cooled system perfectly balanced water consumption and energy efficiency in their arid climate.

Absorption Chillers: Alternative Energy Source

Absorption chillers use heat (often waste heat, steam, or solar energy) rather than mechanical energy to drive the refrigeration cycle:

Low electrical consumption2: Use minimal electricity (typically <15kW for pumps only)

- Utilize waste heat3: Can leverage otherwise wasted heat from processes

- Reduced peak electrical demand: Helpful for facilities with electrical capacity limitations

- Lower efficiency: COP typically around 0.5 for single-effect and 1.0 for double-effect systems

These specialized systems are most applicable where waste heat is available or electricity costs are incredibly high. I helped a manufacturing facility implement an absorption chiller that utilized waste heat from their production process, significantly reducing their electricity consumption despite the lower overall efficiency of the system.

Each cooling method has its place, and the choice depends on your circumstances. Water availability, energy costs, ambient conditions, and maintenance capabilities are crucial in determining which cooling technology will provide the best long-term value for your application.

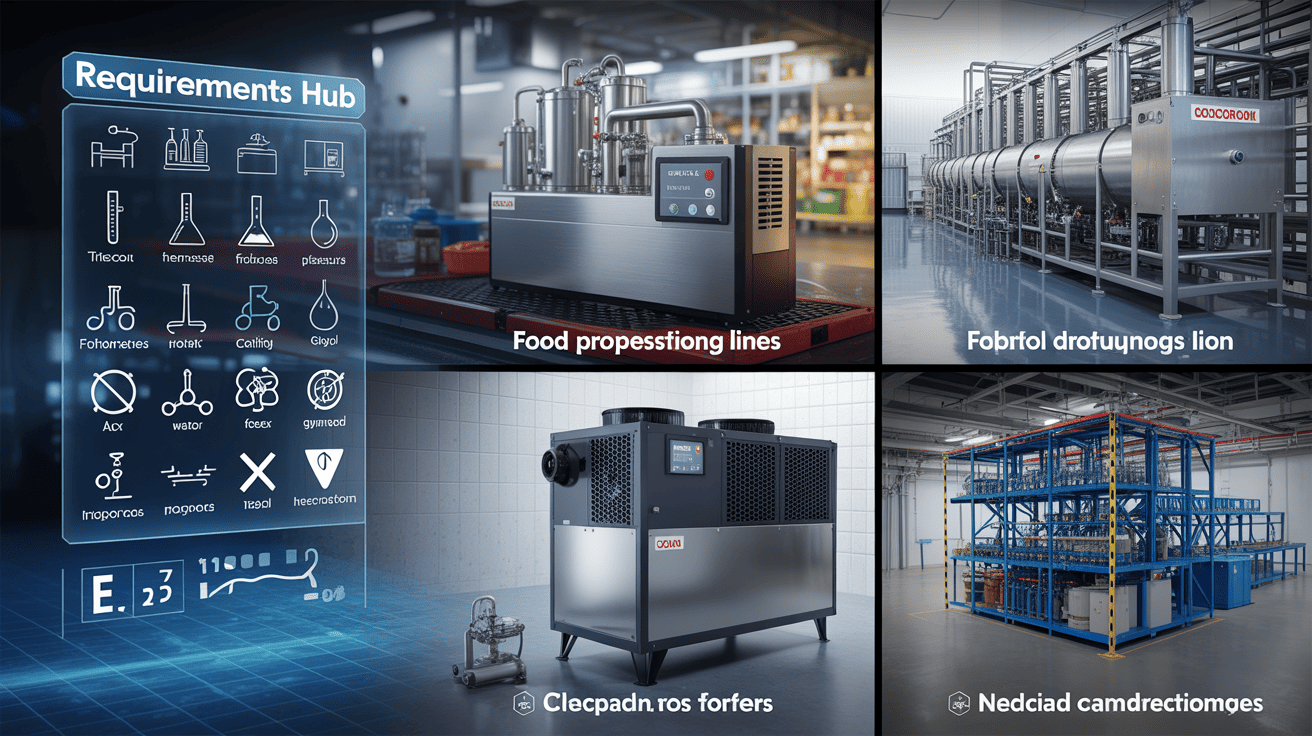

Why Is Understanding Your Application Requirements Critical for Chiller Selection?

I frequently encounter clients focusing solely on cooling capacity without considering their specific process requirements. This oversight leads to chillers that can’t maintain proper temperatures during critical operations or tack features essential for their application.

Understanding your application requirements is essential because different industrial processes have unique cooling demands. Food processing requires precise temperature control and food-grade materials, while metalworking might need chillers capable of handling high temperatures and corrosive fluids. Plastic extrusion may require separate heat exchangers, and chemical plants often need explosion-proof systems for safety.

Each industry and application presents unique challenges that directly impact chiller selection criteria. Through my work with clients across diverse sectors, I’ve found that failing to align chiller specifications with specific process requirements is one of the most common and costly mistakes. Let me walk you through key application considerations.

Process-Specific Temperature and Flow Requirements

Different manufacturing processes have fundamentally different temperature control needs:

Temperature and Flow Requirements by Industry:

| Industry | Temperature Range | Flow Characteristics | Special Considerations |

|---|---|---|---|

| Plastic Injection Molding | 5-95°C | Consistent flow | Temperature stability critical for part quality |

| Procesado de alimentos | 0-10°C | Variable based on product | Food-grade materials required |

| Metal Plating | 15-60°C | High flow rates | Corrosion resistance needed |

| Medical/Laboratory | 2-25°C | Precise flow control | High temperature stability (±0.1°C) |

| Laser Cooling | 20-25°C | Consistent, precise flow | Ultra-stable temperature control |

I worked with a plastic injection molding facility and experienced inconsistent product quality. Their existing chiller provided adequate cooling capacity but lacked the temperature stability for their high-precision parts. By replacing it with a specialized unit designed for injection molding applications, they reduced rejection rates by over 30%.

Coolant Type and Compatibility

The process fluid you need to cool directly influences chiller selection:

-

Water: Simplest option, but limited to above-freezing applications unless additives are used

-

Glycol Solutions: Used for below-freezing applications or freeze protection

- Ethylene glycol: Higher thermal efficiency, but toxic

- Propylene glycol: Food-safe but less thermally efficient

-

Oils: Used for high-temperature applications but require specialized heat exchangers

-

Specialized Fluids: Dielectric fluids for electrical applications or specialized chemicals for specific processes

When assisting a food processing client, we had to ensure adequate cooling capacity and food-grade materials throughout the system. We selected a chiller with stainless steel tanks and propylene glycol as the coolant, guaranteeing safety compliance and reliable performance.

Environmental and Safety Considerations

Your operating environment and safety requirements significantly impact chiller selection:

-

Explosive Atmospheres: Chemical plants may require explosion-proof chillers with appropriate certifications

-

Cleanroom Applications: Semiconductor or pharmaceutical facilities may need specialized designs to prevent contamination

-

Outdoor Installation: Requires weatherproofing, freeze protection, and appropriate IP/NEMA ratings

-

Noise Constraints: Some environments require low-noise chillers to maintain workplace comfort

I recently consulted for a chemical manufacturing facility that needed cooling for its reactor vessels. Standard chillers weren’t suitable due to the potentially explosive atmosphere. We specified a specialized explosion-proof system with remote controls outside the hazardous area, ensuring safety compliance and effective cooling.

Integration with Existing Systems

How your chiller will integrate with existing equipment and controls is another crucial consideration:

-

Control Systems: Ensure compatibility with your facility’s monitoring and control systems

-

Physical Integration: Consider space constraints, piping connections, and access requirements

-

Multiple Load Handling: Some applications require cooling multiple processes at different temperatures

-

Redundancy Requirements: Critical processes may require backup capacity or N+1 configurations

We designed a system with redundant chillers and pumps for a pharmaceutical manufacturer to ensure continuous operation even during maintenance or component failure. This redundancy was essential for their 24/7 process, and they could not tolerate cooling interruptions.

By thoroughly understanding your specific application requirements, you can select a chiller that meets your basic cooling needs and provides the precise performance characteristics and operational capabilities that your process demands. This application-focused approach prevents the common and costly scenario of modifying or replacing a technically adequate but application-inappropriate chiller.

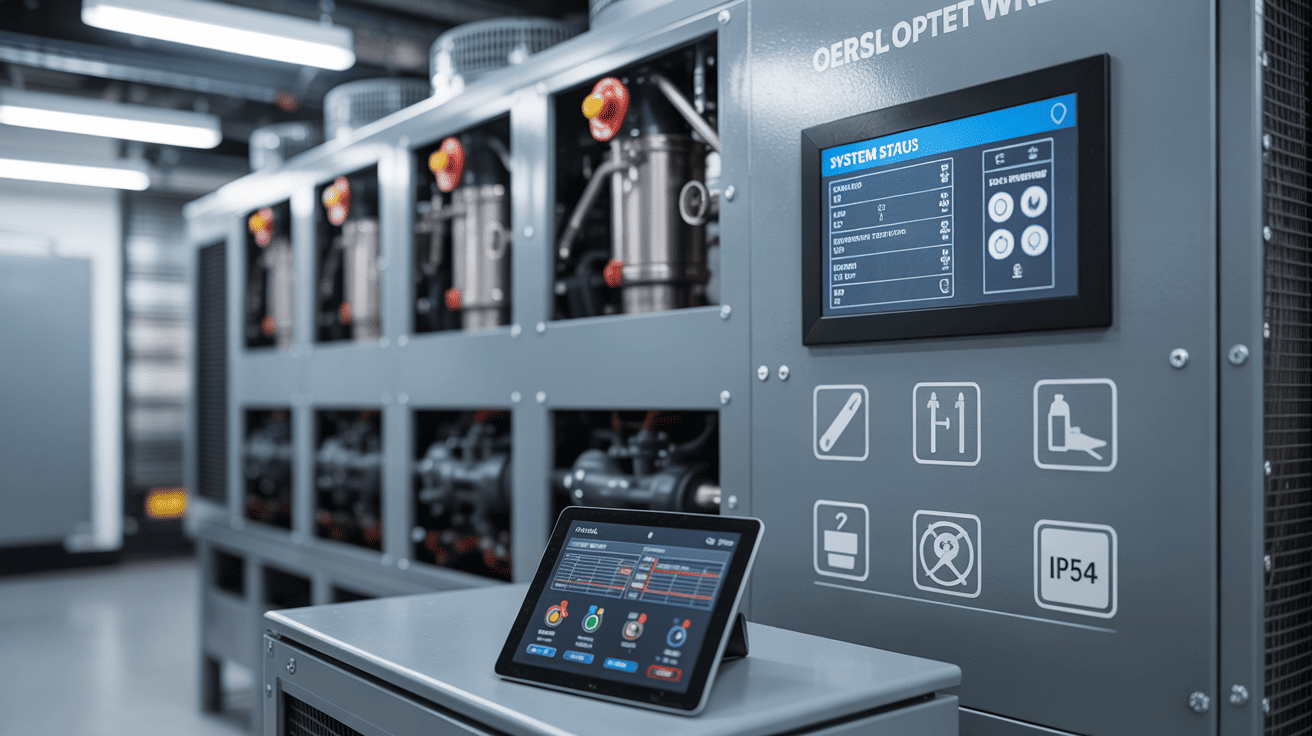

What Maintenance Considerations Should Influence Your Chiller Choice?

I’ve seen clients choose chillers based solely on purchase price, only to struggle with excessive maintenance costs and unexpected downtime. Maintenance accessibility and requirements should be key factors in your decision-making process.

Maintenance considerations4 should significantly influence chiller selection because they impact long-term reliability and operating costs. Look for chillers with easy access to components, safety features like flow switches and thermal probes, and appropriate environmental design (IP54-rated for harsh conditions). Consider inspection requirements like FGAS for certain refrigerants, and evaluate whether advanced control systems can reduce manual maintenance needs.

Maintainability is often overlooked during the selection process, yet it enormously impacts the total cost of ownership and system reliability. Through my years helping clients optimize their cooling systems, I’ve identified several key maintenance factors that should influence your chiller selection decision.

Accessibility and Serviceability

Not all chillers are created equal when it comes to serviceability. Key design features can dramatically impact maintenance time and costs:

Essential Accessibility Features:

-

Component Access: Look for designs with easy access to:

- Pumps and strainers

- Refrigeration components

- Control panels

- Heat exchangers

-

Service Clearances: Ensure adequate space around the chiller for maintenance tasks

-

Diagnostic Accessibility: User-friendly interfaces that provide clear fault information

I recently worked with a food production company, replacing their aging chillers. We prioritized serviceability in their selection criteria and chose a system with hinged access panels and pull-out components. Their maintenance team estimates this has reduced routine service time by approximately 40% compared to their previous equipment.

Safety Features and Protection Systems

Modern chillers should include various safety and protection features that reduce maintenance issues:

| Safety Feature | Function | Maintenance Benefit |

|---|---|---|

| Flow Switches | Prevent operation without adequate flow | Protects pump and prevents overheating |

| Level Switches | Monitor fluid levels | Prevents dry running and system damage |

| Thermal Probes | Monitor critical temperatures | Early warning of potential issues |

| Pressure Probes | Monitor system pressures | Identifies leaks or blockages |

| Strainers | Filter contaminants from fluid | Protects pumps and heat exchangers |

| Crankcase Heating | Prevents refrigerant migration | Extends compressor life |

A manufacturing client I advised was initially reluctant to pay for advanced protection features. After calculating potential downtime costs, they opted for a fully-equipped system. Within the first year, the protection systems prevented two potential major failures, saving an estimated $30,000 in repairs and lost production.

Environmental Considerations for Maintenance

The environment where your chiller operates directly impacts maintenance requirements:

-

Indoor vs. Outdoor Installation: Outdoor chillers need robust designs like IP54-rated canopies that can operate in extreme temperatures as low as -45°C

-

Dusty or Dirty Environments: Require more frequent filter and condenser cleaning

-

Water Quality: Poor water quality5 increases maintenance for water-cooled systems

-

Ambient Temperature Fluctuations: Can impact refrigeration system stability and maintenance needs

For a client operating in a dusty manufacturing environment, we specified a chiller with easily accessible and washable filters plus a coated condenser to reduce maintenance frequency. These features added slightly to the initial cost but saved hours of maintenance time each month.

Refrigeration System Type and Inspection Requirements

Different refrigeration systems have varying maintenance needs:

-

Hermetically Sealed Systems: Lower maintenance, but may require complete replacement if they fail

-

Semi-Hermetic Systems: Allow for component repair but require more regular maintenance

-

FGAS Regulations6: Systems using certain refrigerants require annual or bi-annual inspections

When helping clients select new chillers, I always discuss refrigerant options and their regulatory implications. For a European client with multiple facilities, we selected a refrigerant with a lower GWP (Global Warming Potential)system to reduce environmental impact and regulatory compliance burden.

Control Systems and Remote Monitoring7

Advanced control systems can significantly reduce maintenance needs:

-

Touch Screen Controllers: Provide clear information and troubleshooting guidance

-

Energy-Efficient Algorithms: Available for systems 11 kW and above

-

Remote Monitoring7: Allows for proactive maintenance before failures occur

-

Performance Tracking: Identifies efficiency degradation, indicating maintenance needs

A data center client invested in chillers with advanced monitoring capabilities, integrating with their building management system. This allows them to track performance trends and schedule preventive maintenance based on actual operating conditions rather than fixed intervals, significantly reducing maintenance costs and the risk of unexpected failures.

By thoroughly evaluating these maintenance factors during the selection process, you can avoid the common trap of focusing solely on purchase price and cooling performance. A slightly higher initial investment in a more maintainable system with better support often delivers substantially lower total cost of ownership over the equipment’s life cycle.

Conclusión

Selecting the right industrial chiller requires careful consideration of multiple factors: proper sizing using accurate heat load calculations, choosing the appropriate cooling method for your environment, understanding your specific application requirements, and evaluating maintenance considerations. By thoroughly assessing these elements, you’ll find a chiller solution that delivers optimal performance, efficiency, and reliability for your industrial application, avoiding costly mistakes and ensuring long-term satisfaction.

-

Explore this resource to understand the critical factors in selecting the right industrial chiller for your needs, ensuring efficiency and cost savings. ↩ ↩

-

Exploring this resource will provide insights into energy-efficient chiller technologies that can significantly reduce operational costs. ↩

-

This link will help you understand innovative methods to leverage waste heat, enhancing energy efficiency in cooling applications. ↩

-

Discover essential maintenance factors that can impact the reliability and cost-effectiveness of your chiller system over time. ↩

-

Understanding water quality’s effect on chiller maintenance can help you optimize system performance and reduce costs. ↩

-

Exploring FGAS regulations will help you stay compliant and informed about refrigerant management in your systems. ↩

-

Discover how remote monitoring can enhance maintenance efficiency and reduce unexpected failures in your cooling systems. ↩ ↩