Confused about cooling terms like "chiller" and "refrigerator"? Using the wrong one or misunderstanding their capabilities can be inefficient and costly. Let’s clarify their distinct roles.

Chillers are industrial cooling systems designed for precise, large-scale liquid cooling in processes, while refrigerators are appliances for preserving food or general cooling in smaller, less demanding applications.

It’s easy to get these terms mixed up, as both chillers and refrigerators work on the fundamental principle of removing heat. However, their design, capacity, target temperatures, and intended uses are worlds apart. Understanding these differences is crucial, especially when looking for a solution for your specific operational or personal needs. As General Manager of Kaydeli, where our slogan is "Precision Cooling, Engineered for Your Success," I’ve seen countless times how selecting the appropriate cooling technology is fundamental to efficiency and success. Let’s dive deeper into what sets them apart so you can make an informed decision.

How Do Their Core Functions and Target Temperatures Set Them Apart?

Struggling to see beyond the basic idea of "making things cold"? This oversimplification can lead to inefficient operations or damaged goods. We’ll explore their fundamental purposes and precise temperature capabilities.

المبردات1 provide precise, often very low, temperatures by cooling a liquid for industrial processes, while refrigerators maintain moderately cool temperatures within an enclosed space, primarily for preservation.

The core function and the temperatures they achieve are perhaps the most significant differentiators. While both devices cool, what they cool, how they cool it, and to what extent are vastly different.

The Chiller’s Realm: Process Liquid Cooling and Exactitude

Industrial chillers are the heavy-lifters in many manufacturing, commercial, and technical processes. Their primary job is to remove heat from a liquid (like water or a glycol solution), which then circulates through process equipment or HVAC systems to control temperature accurately. Think about industries like plastics manufacturing, where the temperature of molds needs to be exact – often within ±0.5°C – to ensure product quality and consistency. Or consider large commercial buildings where chillers provide the cooled water for the entire air conditioning system, typically in the 4–7°C range.

I remember a client in the advanced chemical processing sector. They were developing a new compound that required a reaction vessel to be maintained at precisely -25°C, with very little tolerance for fluctuation, for over 24 hours. A standard refrigeration unit wouldn’t even approach this temperature, let alone offer the stability or the capacity to handle the heat load from the reaction. Our Kaydeli engineering team designed a specialized low-temperature chiller using Mr. Li’s profound expertise in industrial refrigeration cycles. This system met their stringent temperature requirements and integrated with their process controls for seamless operation. This is typical for chillers; they are engineered for specific, demanding tasks where precision is non-negotiable. The temperature ranges for chillers can be incredibly broad, from moderately cool for comfort air conditioning down to -40°C or even lower for specialized industrial applications. The key is not just reaching a low temperature, but maintaining it consistently and reliably.

The Refrigerator’s Role: Preservation and Enclosed Space Cooling

Refrigerators2 are designed for less demanding tasks, primarily focused on creating a controlled, calm internal environment. The most common application is food preservation in homes and commercial kitchens. The goal is to keep food items above freezing but cool enough to slow down bacterial growth, typically maintaining the fresh food compartment between 0°C and 4°C. Freezer compartments aim for ≤-18°C for long-term storage. While vital for food safety, this doesn’t require pinpoint accuracy over a dynamic heat load or the extremely low temperatures many industrial chillers provide.

Other refrigerators might be used for beverage cooling, displaying chilled products in retail, or storing temperature-sensitive medications in pharmacies. Some specialized laboratory refrigerators exist for storing samples, but these generally don’t match an industrial chiller’s cooling power or active process cooling design. The focus is on maintaining a typically calm and stable environment within an insulated cabinet, rather than actively managing the temperature of an external, heat-generating process.

What Are the Major Design, Capacity, and Operational Differences We Should Know?

Are you thinking all cooling systems are built with similar guts and power? This assumption can lead to severe underperformance or unnecessary overspending. Let’s examine their construction, cooling power, energy use, and upkeep.

المبردات1 are robustly built with larger capacities and complex components for continuous, heavy-duty industrial use. Refrigerators2 are simpler, smaller, and designed for lighter, often intermittent, duty with a focus on internal volume.

The physical design, cooling capacity, energy profile, and maintenance needs of chillers and refrigerators directly reflect their different jobs. When we at Kaydeli design a chiller, we think about 24/7 reliability under substantial and often fluctuating thermal loads, maximizing energy efficiency at industrial scales, and ensuring the ability to integrate into complex plant operations. This philosophy leads to very different engineering choices compared to those for a standard refrigerator.

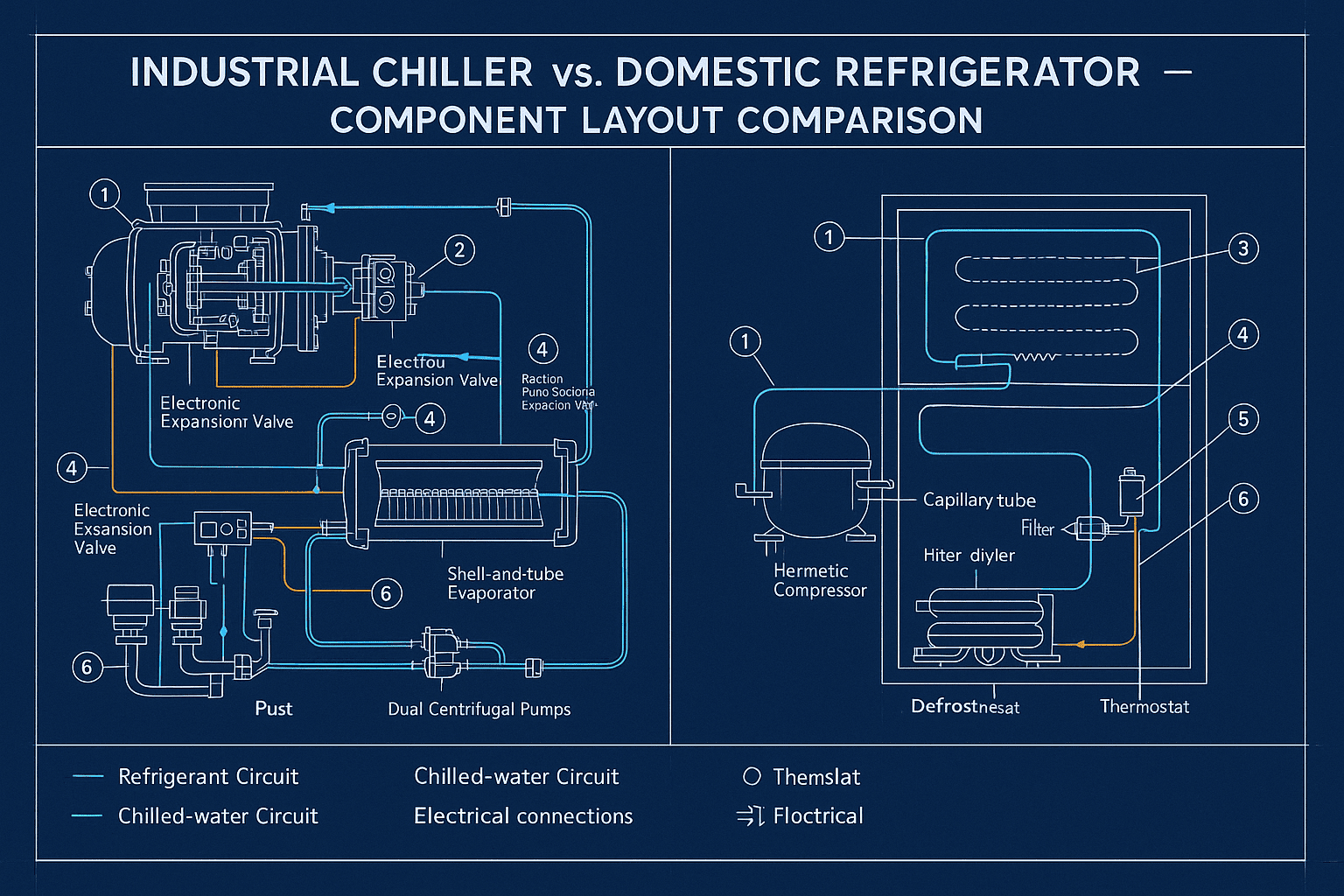

Chiller Design, Capacity, and Operation: Built for Industrial Demands

المبردات1 are engineered for toughness, precision, and high performance. Their components are typically larger, more durable, and designed for continuous operation in demanding industrial environments.

- Design & Components: المبردات1 are often modular systems. They include powerful compressors (screw, scroll, centrifugal), large evaporators and condensers (shell-and-tube, plate, or large finned coils), expansion valves, and often integrated pumps and sophisticated control systems (PLCs). They come in air-cooled variants (releasing heat to ambient air) or water-cooled variants (transferring heat to a water source, often a cooling tower, which are generally more efficient but require more infrastructure). Mr. Li, our CTO, always emphasizes that the selection between air-cooled and water-cooled depends heavily on the installation environment, available utilities, and long-term operational costs.

- Capacity: Chiller capacity is a measure of its heat removal capability, expressed in tons of refrigeration (TR) (1 TR = 3.517 kW) or kilowatts (kW). Capacities can range from a few kW for small laboratory or machine cooling applications to thousands of kW (tons) for large industrial plants, data centers, or district cooling systems. For instance, a 500-ton chiller can remove approximately 1,758 kW of heat.

- Energy Consumption: المبردات1 consume significantly more energy than refrigerators due to their scale and power. A 500-ton air-cooled chiller might consume around 350 kW of power, while a more efficient water-cooled model of the same capacity might use about 250 kW. Modern chillers incorporate energy-saving technologies like Variable Speed Drives (VSDs) on compressors, fans, and recovery systems to improve overall plant efficiency.

- Maintenance & Lifespan: Maintenance is more complex and critical for chillers. It involves regular checks of refrigerant levels, oil analysis, cleaning of condenser coils (for air-cooled) or tubes (for water-cooled, which can include descaling), and calibration of controls. Industrial chillers can have a lifespan exceeding 20 years with proper, diligent maintenance. I’ve seen Kaydeli units performing reliably after two decades in the field, which is a testament to robust design and good upkeep.

Refrigerator Design, Capacity, and Operation: Simplicity for Specific Tasks

Refrigerators2 are designed with user convenience, compactness, and cost-effectiveness for their intended purpose.

- Design & Components: They are typically self-contained, insulated cabinets with doors, shelves, and compartments optimized for food storage or specific item storage. Components like compressors (usually smaller, hermetic reciprocating types), evaporators, and condensers are integrated into a single, compact unit, designed for relatively quiet operation.

- Capacity: Refrigerator capacity is measured by internal storage volume, usually in liters or cubic feet. This can range from small, under-counter units of around 100 liters to large household or commercial units of 700 or more. This reflects how much it can hold, not its dynamic heat removal rate for a process.

- Energy Consumption: Refrigerators2 are designed for energy efficiency in their class, consuming anywhere from 100 to 800 kWh per year, depending on size, features, and efficiency rating.

- Maintenance & Lifespan: Maintenance is generally straightforward: cleaning coils, checking door seals, and occasional defrosting (though many are frost-free). Their lifespan typically ranges from 10 to 20 years.

Here’s a comparative table summarizing these aspects:

| Aspect | Chiller | Refrigerator |

|---|---|---|

| Primary Use | Industrial/Commercial process liquid cooling, HVAC | Food preservation, item storage in an enclosed space |

| Temperature Range | Wide (e.g., 4-7°C HVAC; down to -40°C industrial), precision ±0.5°C | 0–4°C (fresh food), ≤-18°C (freezer) |

| Design Features | Modular, robust, separate/large components, air/water-cooled options | Compact, insulated cabinet, integrated components, user-focused |

| Capacity Measurement | Cooling power (tons or kW, e.g., 500 tons = 1,758 kW) | Storage volume (100–700 liters or cubic feet) |

| Energy Consumption | High (e.g., ~250-350 kW for 500-ton), VSDs for efficiency | Low (100–800 kWh/year) |

| الصيانة | Complex, regular professional servicing, component checks, scale cleaning | Basic (coil cleaning, seal checks, defrosting) |

| Lifespan | 20+ years with good maintenance | 10–20 years |

This detailed comparison should clarify that while both are cool, their engineering and operational parameters are tailored for vastly different scales and purposes.

In Which Specific Applications Do المبردات3 و Refrigerators4 Truly Excel?

Unsure where each cooling type fits best in the real world? Misapplication means wasted resources, poor performance, and potential damage. We’ll highlight their ideal operational environments and typical uses.

المبردات3 excel in demanding industrial, commercial, and scientific settings requiring precise, high-capacity cooling for machinery, processes, and large spaces. Refrigerators4 are ideal for food storage, medical sample preservation, and general light-duty cooling within defined compartments.

Any cooling technology’s actual value and suitability are best seen in its practical applications. At Kaydeli, our focus on "Precision Cooling, Engineered for Your Success" underscores the specialized, critical applications where chillers are beneficial and indispensable. Understanding these distinct application areas helps solidify why their designs, capacities, and operational characteristics differ profoundly.

Chiller Applications: The Powerhouse of Industry, Commerce, and Advanced Technology

المبردات3 are critical components in many sectors where precise and reliable temperature control directly impacts product quality, process efficiency, equipment longevity, and safety. I’ve had the privilege of working with clients across many of these diverse industries, and the innovative ways chillers are employed always amaze me.

- HVAC Systems: Large commercial and institutional buildings like offices, hospitals, hotels, shopping malls, and airports rely on chillers to produce chilled water for their air conditioning systems, ensuring comfort for occupants.

- العمليات الصناعية5: This is a vast area.

- Plastics and Rubber: Injection molding, blow molding, extrusion – all require chillers to cool molds and hydraulic systems, ensuring consistent product dimensions, faster cycle times, and reduced scrap. I recall a plastics company struggling with inconsistent product quality due to temperature variations. Installing a Kaydeli chiller with precise feedback control dramatically improved their output.

- Metalworking & Finishing: Processes like plating, anodizing, and cooling cutting fluids for machine tools depend on chillers to maintain optimal temperatures, improve surface finish, and extend tool life.

- Chemical & Petrochemical: Many chemical reactions are exothermic or require specific temperatures. المبردات3 provide critical cooling to control reaction rates, ensure product purity, and maintain operational safety.

- Food and Beverage Industry (Processing): While refrigerators store finished goods, chillers are vital during processing. Breweries use them to cool wort rapidly; dairies cool milk; beverage plants chill product before bottling. They are also used in large-scale freezing and cooling tunnels.

- Medical and Laboratory Equipment: MRI machines, CT scanners, linear accelerators, and electron microscopes generate significant heat and require dedicated chillers for stable operation and to protect sensitive, expensive components. Precision here is paramount. Mr. Li often highlights our work providing ultra-reliable chillers for these life-saving technologies.

- Data Centers: The density of servers in modern data centers generates immense heat. المبردات3 (often large-capacity water-cooled or air-cooled units) are essential for maintaining optimal operating temperatures, preventing server failure, and ensuring data integrity.

- Pharmaceutical Manufacturing: From API (Active Pharmaceutical Ingredient) production to tablet coating and maintaining controlled environments for sensitive biologicals, chillers are crucial in ensuring product efficacy and compliance with stringent regulations.

Refrigerator Applications: Essential for Preservation and Localized Cooling

Refrigerators4 serve a different, though equally important, set of needs, primarily focused on preservation within an enclosed space and smaller-scale, localized cooling.

- Household Food Storage: This is their most ubiquitous application, keeping perishable foods fresh and safe for consumption in homes worldwide.

- Commercial Food Service & Retail: Restaurants, cafes, supermarkets, and convenience stores use commercial refrigerators, freezers, and refrigerated display cases to store ingredients, prepare food, and present chilled or frozen products to customers.

- Pharmaceutical and Medical Storage (Smaller Scale): Pharmacies, clinics, and hospitals use medical-grade refrigerators and freezers to store vaccines, certain medications, blood products, and patient samples that require stable, cool, or frozen temperatures. These are typically smaller and designed for static storage.

- Laboratory Sample Storage: Scientific and research labs use specialized laboratory refrigerators and freezers to preserve biological samples, chemicals, reagents, and cultures at specific, stable temperatures.

- Beverage Cooling & Vending: Display coolers in stores and beverage vending machines are typical examples of refrigeration used for immediate consumption or retail.

The key distinction remains: refrigerators typically cool a static, insulated volume, while chillers actively cool a dynamic process or a large volume via a heat transfer fluid, demanding greater capacity, robustness, and control precision.

الخاتمة

المبردات3 deliver precise, high-capacity cooling for industrial and large-scale applications by chilling liquids, while refrigerators offer general cooling for preserving items within smaller, enclosed spaces. Recognizing this fundamental difference is key to selecting the right technology for optimal performance, efficiency, and success.

-

Explore this link to understand how chillers are used in various industries for precise cooling needs, enhancing operational efficiency. ↩ ↩ ↩ ↩ ↩

-

Learn about the technology behind refrigerators and their role in food safety and preservation, crucial for everyday life. ↩ ↩ ↩ ↩

-

Explore how chillers are essential for precise cooling in various industries, enhancing efficiency and product quality. ↩ ↩ ↩ ↩ ↩ ↩

-

Learn about the critical role refrigerators play in food safety and storage, ensuring freshness and quality. ↩ ↩ ↩

-

Discover the innovative applications of chillers in industrial processes, improving product consistency and efficiency. ↩