Selecting between air-cooled and water-cooled chillers has been a critical decision that has impacted operational costs and efficiency for years. A hasty choice based on initial cost alone often leads to inefficient operations, excessive maintenance expenses, and premature system replacement.

When choosing between air-cooled and water-cooled chillers, consider your specific application requirements, location, and long-term objectives. Air-cooled chillers offer simpler installation with lower upfront costs and reduced maintenance needs, while water-cooled systems provide superior energy efficiency, longer lifespan, and better performance for larger applications.

Throughout my years helping clients select cooling systems, I’ve noticed this decision often creates confusion. Many factors beyond the initial price tag determine which system will deliver the best value. Let me share insights from my experience to help you navigate this critical choice for your cooling needs.

Which Cooling System Offers Better Energy Efficiency?

Energy costs typically represent 70-80% of a chiller’s lifecycle expenses. I’ve visited numerous facilities where managers were shocked by their utility bills after selecting a system based solely on equipment price.

Water-cooled chillers generally deliver superior energy efficiency1, operating at approximately 0.85 kW/ton compared to air-cooled systems at 1.5 kW/ton. This efficiency advantage comes from water’s superior heat transfer properties and lower condensing temperatures based on wet-bulb rather than dry-bulb readings.

Understanding the Physics Behind Efficiency Differences

The efficiency gap between these systems stems from fundamental thermodynamic principles, as demonstrated in real-world applications. Water-cooled chillers operate with lower condensing temperatures because they utilize cooling towers that reject heat based on the ambient wet-bulb temperature. This is typically 10-15°F lower than the dry-bulb temperature that air-cooled condensers rely on.

This temperature difference significantly impacts the compressor workload. For every 1°F reduction in condensing temperature, chiller efficiency improves by approximately 1-2%. I recall consulting for a pharmaceutical manufacturing facility that switched from air-cooled to water-cooled chillers and documented energy savings of nearly 35%, closely matching theoretical predictions.

However, while water-cooled chillers offer better core efficiency, we must consider the total system. Water-cooled setups require additional energy for condenser water pumps and cooling tower fans. These parasitic loads typically account for 0.1-0.2 kW/ton, slightly reducing the overall efficiency advantage.

Efficiency Considerations Based on Application and Climate

| Factor | Air-Cooled Performance | Water-Cooled Performance |

|---|---|---|

| Climate Impact | Efficiency drops in hot weather (>95°F) | Maintains efficiency in hot weather |

| Part-Load Efficiency | Modern VFD systems improve performance | Excellent with variable speed drives |

| Capacity Range | Best for smaller applications (<500 tons) | Superior for larger loads (up to 4,000 tons) |

| Peak Load Performance | Struggles during hottest days | Maintains consistent performance |

| Water Considerations | No water consumption | Requires 2-3 gallons/minute/ton |

Climate conditions significantly influence the efficiency equation. Water usage’s operational constraints and costs may outweigh efficiency benefits in regions facing water scarcity (currently affecting 2 billion people worldwide and projected to reach 4.6 billion in the coming decades).

I’ve worked with clients in desert environments where air-cooled chillers with advanced technologies like adiabatic pre-cooling and variable-speed compressors delivered better overall value despite the theoretical efficiency advantage of water-cooled systems. In one data center project in a water-restricted area, we implemented an air-cooled solution with economizers that achieved comparable efficiency to water-cooled alternatives while eliminating water consumption concerns.

The key takeaway from my experience is that while general efficiency trends favor water-cooled systems, your specific circumstances—including climate, facility size, load profile, and resource availability—must guide your final decision.

How Do Installation and Maintenance Requirements Differ?

The practical aspects of installing and maintaining these systems significantly impact their total cost of ownership2. I’ve seen projects where installation complexities added unexpected costs that took years to recover through efficiency gains.

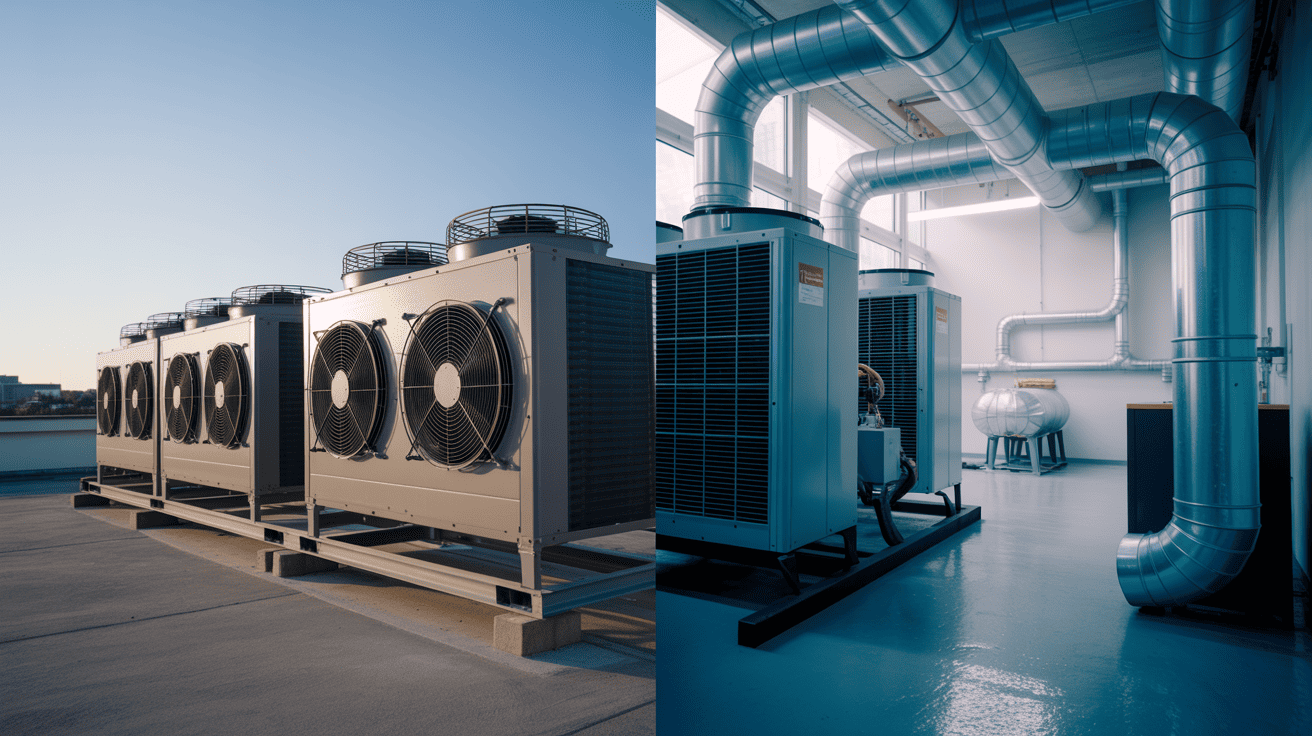

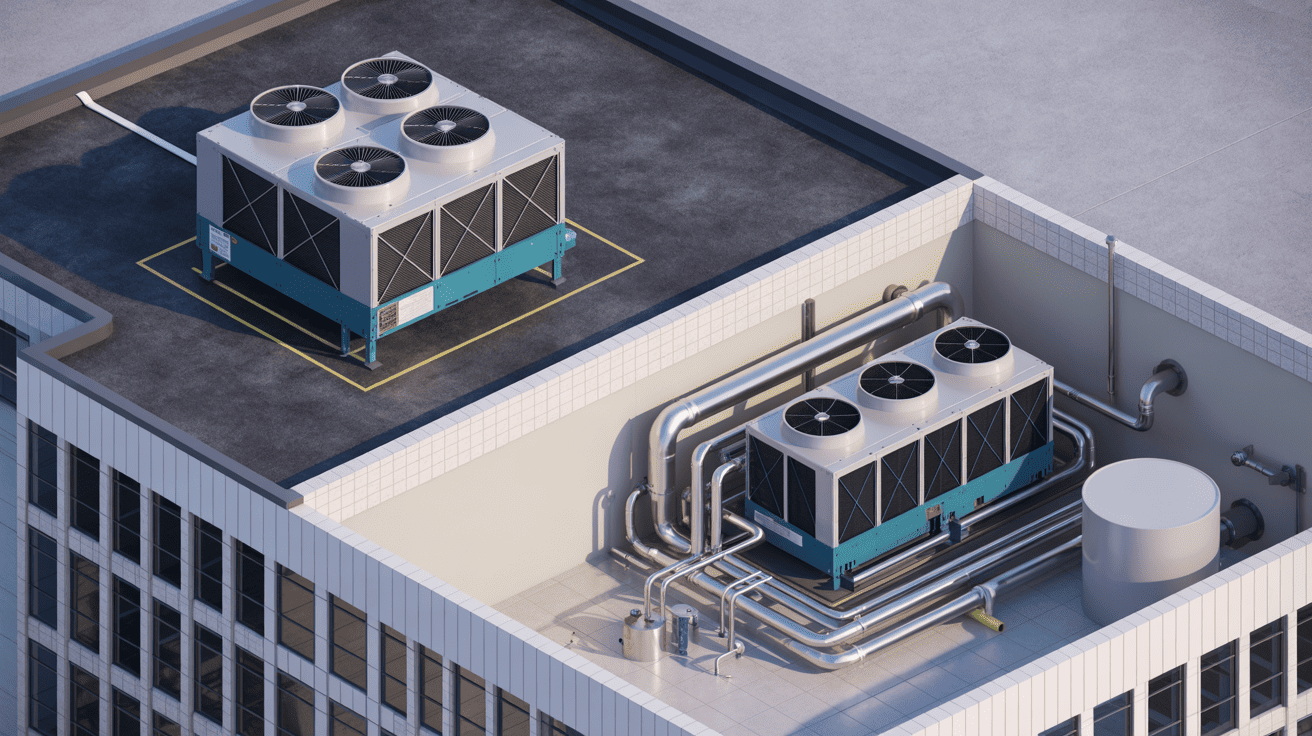

Air-cooled chillers require only electrical connections and chilled water piping, allowing for more straightforward, faster installation. Water-cooled systems demand cooling towers, condenser water pumps, water treatment systems, and more complex piping, increasing installation costs3 by 20-40% and extending timelines considerably.

Space Requirements and Installation Considerations

These systems’ physical footprint and infrastructure needs create practical constraints that often determine feasibility regardless of other factors. I recently consulted on a hospital expansion where space limitations made a water-cooled system the only viable option despite the client’s initial preference for air-cooled simplicity.

Air-cooled chillers typically require outdoor installation with adequate clearance for proper airflow—generally 4-6 feet on all sides. For a 200-ton system, you might need approximately 400 square feet of outdoor space. These units must also be placed with consideration for noise levels, which typically range from 88- 100+ dB, potentially requiring sound attenuation in noise-sensitive environments.

Water-cooled chillers are installed indoors in mechanical rooms, with the chiller itself requiring less space than equivalent air-cooled units. However, the total system footprint, including cooling towers, can be considerable, though these components can be distributed across different facility areas. The chiller room needs proper ventilation, drainage systems, and structural support. Noise levels are generally lower, typically in the 70s-90s dB range, making them more suitable for noise-sensitive applications.

Maintenance Requirements and Long-term Reliability

| Maintenance Aspect | Air-Cooled Systems | Water-Cooled Systems |

|---|---|---|

| Annual Maintenance Cost | 2-3% of initial cost | 3-5% of initial cost |

| Primary Maintenance Tasks | Condenser coil cleaning, refrigerant checks | Water treatment, tower maintenance, tube cleaning |

| Service Frequency | Quarterly inspections | Monthly water treatment, quarterly system checks |

| System Lifespan | 15-20 years | 20-30 years |

| Most Common Issues | Condenser fouling, fan motor failures | Scale formation, corrosion, biological growth |

From my experience managing cooling systems across various facilities, water-cooled systems demand more regular attention but generally offer longer service life. Water treatment is particularly critical—I’ve witnessed excellent systems fail prematurely due to inadequate water quality management. For a mid-sized system, chemical treatment programs typically cost $10,000-$20,000 annually, and cooling towers require regular cleaning and component replacement.

Air-cooled systems, while requiring less frequent maintenance, face their challenges. The condenser coils are directly exposed to outdoor elements and accumulate dirt, pollen, and debris that can reduce heat transfer efficiency by 10-15% if not regularly cleaned. I recommend quarterly inspections and at least annual thorough cleaning to prevent performance degradation.

Another consideration is refrigerant containment. Air-cooled systems typically contain more refrigerant and are more susceptible to leaks outdoors due to vibration and weather exposure. Water-cooled systems generally have lower leak rates due to their controlled indoor environment, an essential factor considering refrigerants’ increasing costs and environmental impact.

Which System Provides Better Return on Investment?

The financial analysis extends far beyond the initial purchase price. Having analyzed dozens of installations over my career, I’ve found that making ROI calculations based on comprehensive lifecycle costs reveals surprising results.

Air-cooled chillers have lower upfront costs (approximately $1,300/ton or $260,000 for a 200-ton system) but higher operating expenses. Water-cooled chillers require greater initial investment (roughly $1,700/ton or $340,000-$400,000 for equivalent capacity) but offer energy savings of approximately $53,040 annually for a 200-ton system, potentially providing payback in just over 2 years.

Breaking Down the Initial Investment

Understanding the total installed cost difference requires looking beyond equipment prices. Based on projects I’ve overseen, here’s how the costs typically distribute:

For air-cooled chillers, major cost components include:

- Chiller equipment: 65-75% of total cost

- Installation labor: 15-20% of total cost

- Electrical infrastructure: 5-10% of total cost

- Chilled water piping: 5-10% of total cost

For water-cooled chillers, the distribution shifts significantly:

- Chiller equipment: 40-50% of total cost

- Cooling tower: 15-20% of total cost

- Condenser water pumps and piping: 10-15% of total cost

- Water treatment system: 5-10% of total cost

- Installation labor: 20-25% of total cost

- Electrical connections: 5% of total cost

This breakdown explains why the initial investment differs so dramatically between systems. The additional components required for water-cooled systems create higher upfront costs but contribute to superior efficiency.

Comprehensive Lifecycle Cost Analysis

To accurately evaluate ROI, we must consider all costs across the equipment’s lifespan. I typically use a 20-year analysis period when advising clients, as this represents these systems’ average service life expectancy.

Using data from real installations and industry standards, here’s what our analysis includes:

- Initial capital costs: Equipment, installation, and infrastructure

- Energy costs: Based on efficiency (0.85 kW/ton vs 1.5 kW/ton), usage patterns, and local utility rates

- Maintenance costs: Regular service, repairs, and component replacements

- Water costs: For water-cooled systems4 only (makeup water for evaporation and blowdown)

- Replacement costs: Major components that may need replacement during the analysis period

- Residual value: Remaining value at the end of the analysis period

For a 200-ton system operating 16 hours per day at 85% load for 300 days annually with electricity at $0.10/kWh, the annual energy cost would be approximately $69,360 for a water-cooled system versus $122,400 for an air-cooled system—a difference of $53,040 annually.

With an additional initial investment of approximately $110,000 for the water-cooled option, the simple payback period would be about 2.07 years. Even accounting for water-cooled systems4‘ higher maintenance costs of $10,000-$20,000 annually, the net savings still support a compelling ROI for long-term ownership.

However, in specific scenarios with advanced technologies, this equation can change. I recently evaluated a facility where an air-cooled variable speed centrifugal chiller5 delivered lower total operating costs than a water-cooled screw chiller for a 140-ton load, highlighting that technological advancements are narrowing the gap in specific applications.

Conclusion

Choosing between air-cooled and water-cooled chillers requires balancing multiple factors. Water-cooled systems generally offer superior efficiency and longevity for larger applications. At the same time, air-cooled chillers provide a more straightforward installation and lower maintenance for smaller needs or water-scarce areas. Your best choice depends on your specific application, location, resources, and long-term operational priorities.

-

Exploring energy efficiency can help you understand how to reduce operational costs and improve system performance. ↩

-

Learning about total cost of ownership can help you make informed decisions that maximize your investment in cooling systems. ↩

-

Understanding installation costs is crucial for budgeting and planning your cooling system project effectively. ↩

-

Explore the advantages of water-cooled systems to understand their efficiency and cost-effectiveness in HVAC applications. ↩ ↩

-

Discover the benefits of air-cooled variable speed centrifugal chillers and how they can optimize energy efficiency in cooling systems. ↩