- Kaydeli

- 120°C High-Temperature Screw Heat Pump

120°C High-Temperature Screw Heat Pump

Catalog:Heat Pumps Chillers

Determine the right cooling capacity for your setup by estimating kilowatt requirements per hour. 🤓

💧 Cooling Capacity: kW

🏷️ Recommended Model:

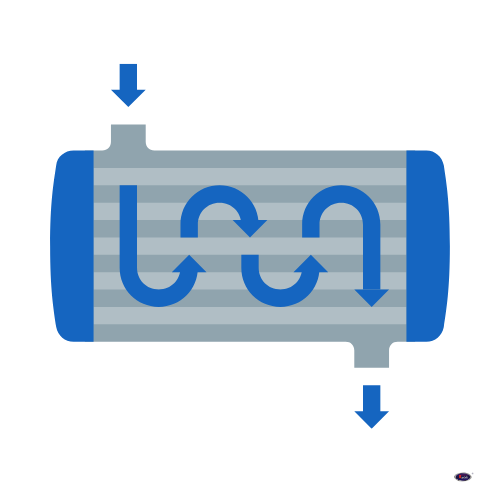

Simplified Working Principle of Heat Pumps

Heat pumps operate by absorbing heat from the air, compressing it to increase energy, releasing the heat for use, and recycling the refrigerant for continuous heating or cooling.

Heat Absorption

Compression

Heat Release

Expansion

What is a 120°C High-Temperature Screw Heat Pump?

The 120°C High-Temperature Screw Heat Pump is an advanced heating solution designed to deliver reliable and energy-efficient heating for industrial processes that require high-temperature outputs. Its innovative design allows it to achieve temperatures up to 120°C, making it a perfect choice for demanding applications in industries such as chemical processing, food manufacturing, and district heating.

| Key Characteristic | Description |

|---|---|

| High Temperature Capability | Delivers consistent heat outputs up to 120°C, ideal for demanding industrial applications such as sterilization, drying, and chemical processing. |

| High-Performance Screw Compressor | Efficiently compresses refrigerants to achieve high temperatures while minimizing energy waste, ensuring long-term reliability in harsh environments. |

| Energy Efficiency | Captures waste heat and leverages variable-speed technology to match load demand, significantly reducing energy consumption and operational costs. |

| Environmentally Friendly Design | Uses low-GWP refrigerants to comply with environmental regulations and supports renewable and waste heat integration. |

| Precise Temperature Control | Incorporates advanced control systems for consistent and accurate temperature regulation, ensuring optimal performance in processes requiring strict thermal management. |

| Stage | Description |

|---|---|

| Heat Absorption | Heat is absorbed from renewable sources like industrial waste heat, geothermal energy, or water, and transferred to a refrigerant in the evaporator, causing it to evaporate into a low-pressure gas. |

| Compression | The refrigerant gas is compressed by a screw compressor, significantly increasing its temperature and pressure, making it suitable for high-temperature applications. |

| Heat Release | The high-pressure, high-temperature refrigerant releases heat in the condenser, heating the working medium (e.g., water) to temperatures of up to 120°C. |

| Expansion | After releasing heat, the refrigerant’s pressure and temperature are reduced through an expansion valve, preparing it to repeat the cycle. |

120°C Screw Heat Pump vs Boilers & Air Source Systems

Compare the 120°C High-Temperature Screw Heat Pump with traditional boilers and air source systems. Discover its superior energy efficiency, eco-friendliness, and industrial versatility.

| Feature | 120°C High-Temperature Screw Heat Pump | Traditional Boilers | Air Source Heat Pumps |

|---|---|---|---|

| Energy Source | Utilizes renewable water-based heat sources (e.g., waste heat, geothermal energy). | Relies on fossil fuels such as coal, oil, or natural gas. | Extracts heat from ambient air, performance drops significantly in cold climates. |

| Efficiency | High Coefficient of Performance (COP) exceeding 4.0, ensuring low energy consumption. | Lower efficiency due to heat loss during combustion. | Moderate efficiency; highly dependent on ambient temperatures. |

| Environmental Impact | Eco-friendly with minimal carbon emissions using low-GWP refrigerants. | High carbon emissions due to burning fossil fuels, contributing to global warming. | Low emissions but reduced efficiency in extreme weather conditions. |

| Temperature Range | Delivers consistent heat up to 120°C, suitable for industrial applications. | Can produce high temperatures but requires significant energy input. | Limited to moderate temperatures, typically up to 70°C–80°C. |

| Operational Cost | Lower operational costs due to energy efficiency and heat recovery. | Higher costs due to fuel dependency and heat loss. | Moderate operational costs but higher in colder climates due to inefficiency. |

| Applications | Ideal for food processing, textiles, pharmaceuticals, and district heating. | Mostly used in legacy systems or for very high-temperature needs. | Best for residential or light commercial use; limited industrial applications. |

Resources

Heating Requirements

Heating Capacity Needs

Selecting the appropriate heating capacity for a 120°C High-Temperature Screw Heat Pump is essential for ensuring optimal performance, cost efficiency, and long-term reliability. Here’s how to determine your heating capacity needs:

| Aspect | Details |

|---|---|

| 📏 Process Heating Requirements |

- Calculate heating demand for specific processes like sterilization or drying. - Measure energy needs in kW or BTUs based on operational scale. |

| 🏭 Application Size |

- Larger facilities require higher capacity units. - Use modular systems for flexible scalability in growing operations. |

| 🌡️ Heat Loss |

- Poor insulation increases heat loss, requiring higher capacity to compensate. - Factor in ambient temperatures and humidity for precise sizing. |

| 📊 Industry Examples |

Food and Beverage: 100–300 kW for sterilization and pasteurization. Pharmaceutical: 200–500 kW for steam sterilization processes. Textile Industry: 300–800 kW for dyeing and finishing. District Heating: 500 kW–1 MW for centralized heating systems. |

| 🔄 Future Scalability |

- Choose a system slightly exceeding current heating needs to allow for growth. - Modular setups enable scaling without complete system replacement. |

Where 120°C High-Temperature Screw Heat Pumps Excel

The 120°C High-Temperature Screw Heat Pump is designed for demanding industrial and commercial applications that require consistent, high-temperature heating. Here are the key scenarios where this system performs exceptionally well:

Textile and Garment Industry

•Applications:

Heating processes for dyeing, washing, and fabric finishing.

Maintaining humidity levels for fabric quality.

•Benefits:

Delivers consistent heat for uniform fabric processing.

Reduces energy consumption in large-scale operations.

Pharmaceutical and Chemical Manufacturing

•Applications:

Steam sterilization of medical tools and production equipment.

High-temperature processes like distillation and chemical reactions.

•Benefits:

Ensures compliance with strict hygiene and safety standards.

Reduces carbon emissions compared to fossil fuel-based systems.

Food and Beverage Processing

•Applications:

Steam generation for sterilizing food containers and processing equipment.

Cooking, pasteurization, and drying of food products.

•Benefits:

Precise temperature control ensures food safety and quality.

Energy-efficient operation reduces operational costs compared to traditional boilers.

District Heating Systems

•Applications:

Centralized heating for residential, commercial, and industrial buildings.

Supplying hot water and space heating across urban areas.

•Benefits:

Provides cost-effective and sustainable heating for large-scale communities.

Supports renewable energy integration for greener operations.

Temperature Requirements for 120°C High-Temperature Screw Heat Pumps

The 120°C High-Temperature Screw Heat Pump is designed to operate efficiently across a variety of temperature conditions, delivering consistent high-temperature heating for demanding industrial applications. Understanding the temperature requirements is essential to ensure optimal performance and system longevity.

| Aspect | Details |

|---|---|

| 🌡️ Optimal Operating Temperature |

- Output temperatures reach up to 120°C, ideal for high-temperature industrial processes. - Input heat source temperature operates best between 10°C and 25°C for efficient heat absorption. |

| ❄️ Low-Temperature Input |

- Performs efficiently even with source temperatures as low as 5°C. - Additional pre-heating mechanisms may be required for extremely low input temperatures. |

| 🔥 High-Temperature Applications |

- Capable of maintaining consistent output temperatures from 100°C to 120°C. - Ideal for sterilization, drying, and chemical processes requiring high-grade heat. |

| 🏭 Industry-Specific Needs |

Food and Beverage: 80°C–120°C for sterilization and pasteurization. Pharmaceutical: 100°C–120°C for steam sterilization. Textile Industry: 70°C–100°C for dyeing and finishing. Chemical Manufacturing: 90°C–120°C for distillation and reactions. |

| 🌍 Environmental Factors |

- Performance is unaffected by ambient temperatures due to stable water-based heat sources. - Proper insulation is essential to prevent heat loss during high-temperature applications. |

| ✅ Benefits of Proper Temperature Matching |

- Ensures optimal efficiency, minimizing energy waste. - Prolongs system lifespan by avoiding unnecessary strain. - Reduces operational costs while maintaining reliable performance. |

Installation and Maintenance

Proper installation and consistent maintenance are essential for ensuring the efficient and reliable operation of 120°C High-Temperature Screw Heat Pumps. This section provides a comprehensive guide to achieving optimal performance and long-term durability.

Installation Guidelines

📍 Site Preparation

Ensure sufficient space for the heat pump and its components, allowing proper airflow and easy access for maintenance. Position the system close to the heat source (e.g., water or industrial waste heat) to minimize piping costs and heat loss.

🔧 System Integration

Verify compatibility with existing industrial processes or heating systems. Engage professional technicians to securely connect the system to power, water, and other utilities.

🌊 Water Quality Considerations

Assess water quality for potential impurities requiring filtration or treatment before use. Ensure a stable and consistent water supply to maintain optimal heat pump performance.

🛠️ Initial Testing

Test all components, including compressors, valves, and controls, to ensure proper operation. Confirm the system delivers consistent heat output at the required temperature range (up to 120°C).

Maintenance Best Practices

Routine maintenance is key to preserving the efficiency and longevity of Screw Type Chillers. Here are essential maintenance steps:

| Maintenance Task | Details |

|---|---|

| 🧼 Regular Cleaning |

- Clean heat exchangers and water filters to prevent scaling, corrosion, or debris buildup that can reduce efficiency. - Flush the water circuit periodically to maintain smooth operation. |

| ⚙️ Component Inspections |

- Regularly inspect critical parts like compressors, pumps, and valves for signs of wear or damage. - Monitor refrigerant levels and top up if necessary to ensure efficient operation. |

| 🔍 Performance Monitoring |

- Use smart monitoring systems (if available) to track temperature output, energy consumption, and system performance. - Set up alerts for irregularities to address issues proactively. |

| 📅 Scheduled Servicing |

- Schedule annual professional servicing to perform in-depth inspections, recalibrate controls, and replace worn components. - Check and optimize system efficiency to prevent unexpected downtime. |

| 🌡️ Water Quality Management |

- Regularly test water for pH levels and impurities to prevent scaling and ensure longevity of the heat exchangers. - Install a water treatment system if operating in areas with poor water quality. |

Benefits of Proper Installation and Maintenance

•Energy Efficiency: Maintains consistent performance, reducing operational energy costs.

•Longevity: Prevents component failures and extends the system’s lifespan.

•Reliability: Ensures continuous high-temperature output, even during peak demand periods.

•Cost Savings: Avoids costly repairs and minimizes system downtime.

Energy Efficiency and Cost-Effectiveness

The 120°C High-Temperature Screw Heat Pump is designed to deliver exceptional energy efficiency while significantly reducing operational costs. This makes it an ideal solution for industries looking to balance high-performance heating with long-term sustainability.

Superior Energy Efficiency

Achieves exceptional performance with high COP values, efficient heat recovery, and minimal energy loss, ensuring optimal heating with reduced energy consumption.

⚡ High Coefficient of Performance (COP)

Achieves COP values above 4.0, meaning the system generates over four units of heat for every unit of electricity consumed.

🔄 Efficient Heat Recovery

Captures and reuses waste heat from industrial processes, reducing overall energy consumption.

📉 Minimal Energy Loss

Advanced screw compressor technology ensures precise energy usage, with minimal waste during heat transfer.

Operational Cost Savings

Lowers utility bills and maintenance costs by optimizing energy use, leveraging durable components, and integrating smart control systems for real-time efficiency.

💡 Reduced Energy Costs

Energy-efficient operation directly lowers utility bills for heating and steam generation.

🛠️ Lower Maintenance Costs

Durable components and simplified system design reduce the frequency and cost of maintenance.

🖥️ Smart Control Systems

Optimizes energy usage by adjusting output to match real-time heating demand, further reducing operating expenses.

Long-Term Sustainability

Supports environmental goals with low-GWP refrigerants, renewable energy integration, and compliance with stringent sustainability standards, reducing carbon emissions.

🌍 Environmentally Friendly Design

Utilizes low-GWP refrigerants, significantly reducing carbon emissions and supporting sustainability goals.

🌱 Renewable Energy Integration

Compatible with renewable heat sources such as industrial waste heat or geothermal energy, further decreasing environmental impact.

📜 Compliance with Regulations

Helps industries meet strict environmental and energy efficiency standards, avoiding penalties or fines.

Cost-Benefit Analysis

Highlights the economic advantages of choosing energy-efficient systems over traditional boilers, including reduced energy costs, minimal maintenance, and eco-friendly operations.

| Factor | Traditional Boilers | 120°C High-Temperature Screw Heat Pump |

|---|---|---|

| Energy Consumption | High, due to fossil fuel combustion. | Low, with COP > 4.0 ensuring efficiency. |

| Operational Costs | High utility bills from fuel usage. | Reduced costs through heat recovery. |

| Maintenance Costs | Frequent servicing due to combustion. | Minimal due to durable components. |

| Environmental Impact | High carbon emissions. | Low emissions with eco-friendly refrigerants. |

Why Choose Energy-Efficient Systems?

•Cost Savings: Lower operational costs provide a quick return on investment.

•Sustainability Goals: Supports global efforts to reduce carbon footprints and achieve energy efficiency.

•Reliable Performance: Ensures consistent high-temperature outputs while maintaining minimal energy use.

Brand and After-Sales Support

Investing in a 120°C High-Temperature Screw Heat Pump from Kaydeli means not just getting a high-performance product but also benefiting from industry-leading after-sales services. Kaydeli ensures that your system operates at peak efficiency and delivers long-term value.

Why Choose Kaydeli?

Kaydeli is a global leader in energy-efficient heating and cooling solutions, renowned for its innovative technologies and exceptional customer support. Here’s why Kaydeli stands out:

Exceptional Quality Standards

Kaydeli’s chillers are built using industrial-grade materials and advanced technology, ensuring durability and consistent performance in extreme conditions.

Industry-Specific Expertise

Years of experience in diverse industries enable Kaydeli to deliver tailored solutions that meet the unique requirements of each application.

Sustainability Commitment

Kaydeli prioritizes eco-friendly designs by integrating energy-efficient components and environmentally friendly refrigerants.

Proven Reliability

Trusted by leading companies worldwide, Kaydeli chillers consistently deliver precise, efficient cooling for critical processes.

Comprehensive After-Sales Support

Kaydeli ensures peace of mind with a robust after-sales program designed to maximize product performance and lifespan

Professional Installation Assistance

Expert guidance during setup ensures your chiller operates efficiently from the start.

Customized Maintenance Plans

Tailored maintenance schedules help maximize chiller performance and minimize downtime.

24/7 Technical Support

Kaydeli’s dedicated support team is always available to address issues promptly, ensuring uninterrupted operations.

Warranty and Repair Services

Comprehensive warranty options protect your investment, with fast, efficient repair services.

Customer Feedback and Case Studies

Hearing from other users can be invaluable when selecting the right chiller. Here are some highlights of customer feedback from various industries that use Kaydeli chillers:

FreshTaste Food Processing Ltd.

Kaydeli’s heat pump not only improved our efficiency but also helped us meet environmental standards. It’s been an excellent investment!

PharmaCare Solutions

Kaydeli’s system ensures we meet the highest quality standards while staying energy-efficient. Highly recommended!

GlobalTextiles Group

The Kaydeli heat pump is a game-changer for our production line. We’ve seen noticeable cost savings and consistent results.